Parts for Caterpillar 3412C - Cylinder Head Section

Loading...

Loading... Caterpillar 3412C Cylinder Head Parts Catalog

The Caterpillar 3412C is a legendary engine in the heavy-duty diesel lineup, widely respected in marine propulsion, offshore drilling, industrial power generation, and construction equipment. Known for its ability to operate under extreme conditions, the 3412C depends on a properly functioning cylinder head assembly to maintain performance and efficiency.

The cylinder head forms the upper sealing surface of the combustion chamber. It houses the intake and exhaust valves, guides, springs, rotocoils, injector nozzles, and other related hardware. Any wear or failure in these parts can compromise compression, fuel efficiency, and ultimately, the reliability of your Caterpillar engine.

This catalog provides a comprehensive overview of cylinder heads and related components for Caterpillar 3412C engines, including coverage where applicable for 3412 and 3412B engines.

Complete Cylinder Heads

Bare Cylinder Head for 3412C

The bare cylinder head option is delivered without valves or springs, making it ideal for rebuilders who want to customize their setup. This is often chosen by shops that already have replacement valve train components or prefer to install premium aftermarket parts during assembly.

-

Application: Caterpillar 3412, 3412B, and 3412C engines

-

Benefit: Maximum flexibility during overhaul projects

-

Use Case: Recommended for operators seeking cost control and precision assembly

Cylinder Head with Valves and Springs Installed

A fully assembled cylinder head comes complete with valves and springs already installed, offering a ready-to-install solution. This option drastically reduces downtime and ensures that valve clearances, seating, and spring tension are already matched.

-

Application: Caterpillar 3412, 3412B, and 3412C engines

-

Benefit: Saves time during rebuilds and minimizes the chance of installation errors

-

Use Case: Best for operators who want fast turnaround with OEM-level reliability

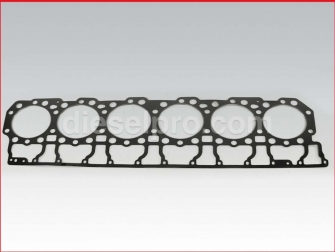

Cylinder Head Gasket Sets

The gasket set provides the necessary sealing components for a top-end rebuild. A complete kit includes the cylinder head gaskets, seals, and associated hardware needed to maintain proper compression and prevent leaks.

-

Coverage: Typically one set per engine, designed to cover two heads

-

Function: Maintains combustion chamber sealing and prevents cross-contamination of coolant and oil

-

Compatibility: Designed for Caterpillar 3412 engines with specific serial number prefixes such as 3JK, 7BL, 7HG, 9KS, and 9PW

-

Importance: Critical for any overhaul, since worn gaskets can cause overheating, oil dilution, and loss of compression

Cylinder Head Fasteners and Hardware

Head Bolts

Cylinder head bolts play a vital role in securing the head to the block and maintaining clamping force under extreme combustion pressures. For the 3412C, specialized heavy-duty bolts are required to prevent head warping and gasket failure.

-

Applications: Used across Caterpillar 3406, 3408, 3412, and 3412C engines

-

Features: Heat-treated steel, high tensile strength, precision-machined threads

-

Benefit: Ensures long-term structural stability under heavy load cycles

Head Bolt Washers

Washers distribute torque evenly and prevent galling or damage to the cylinder head surface during bolt tightening.

-

Applications: Compatible with Caterpillar 3406, 3408, 3412, C15, and C18 engines

-

Benefit: Essential for maintaining even torque distribution and preventing premature wear

Intake and Exhaust Valves

Intake Valves

The intake valves regulate the flow of fresh air into the combustion chamber. They are manufactured to withstand high temperatures, maintain precise seating, and deliver optimal airflow.

-

Applications: Caterpillar 3408, 3412, and 3412C engines

-

Compatibility: Supplied for a wide range of arrangement numbers across multiple engine configurations

-

Benefit: Restores combustion efficiency, ensures smooth air delivery, and supports maximum power output

Exhaust Valves

Exhaust valves manage the removal of hot gases from the combustion chamber. Designed to resist extreme heat and wear, they are critical to maintaining reliable performance under continuous-duty cycles.

-

Applications: Caterpillar 3406, 3408, 3412, and 3412C engines

-

Benefit: Reduces back pressure, prolongs turbocharger life, and ensures consistent exhaust flow

Valve Train Components

Rotocoils

Rotocoils are installed on intake and exhaust valves to promote even rotation, reducing localized wear and extending valve and seat life.

-

Applications: Caterpillar 3408, 3412, and 3412C

-

Benefit: Enhances valve longevity and prevents premature seat failure

Valve Guides

Valve guides keep valves aligned as they open and close, reducing side load stress and maintaining correct seating.

-

Applications: Caterpillar 3406, 3408, and 3412

-

Benefit: Ensures consistent performance and reduced oil consumption

Valve Guide Oil Shields

These shields protect valve guides from excessive oil exposure and contamination, keeping the combustion chamber clean.

-

Applications: Caterpillar 3412 and 3412C

-

Benefit: Prevents oil fouling and extends guide life

Valve Inserts

Valve seat inserts provide a hardened surface for intake and exhaust valves to seal against. They are designed to withstand extreme pressure and heat cycles.

-

Applications: Caterpillar 3406, 3408, and 3412

-

Benefit: Prevents seat erosion and improves valve seating consistency

Valve Springs

Valve springs maintain proper tension and ensure that intake and exhaust valves return to their closed position.

-

Applications: Caterpillar 3400 series engines

-

Benefit: Critical for accurate timing and preventing valve float

Valve Locks

Valve locks secure the spring retainer to the valve stem, ensuring the entire assembly remains in place during high-speed operation.

-

Applications: Caterpillar 3400 series engines

-

Benefit: Small but essential—failure can cause catastrophic valve damage

Cylinder Head Seals and Gaskets

Cylinder Head Gaskets

Head gaskets are installed between the cylinder head and the block, sealing combustion pressures and fluid passages.

-

Applications: Caterpillar 3412, 3412C, and 3412E engines

-

Benefit: Two are required per engine to ensure proper sealing

Precombustion Chamber Gaskets

These gaskets prevent leaks between the precombustion chamber and cylinder head.

-

Applications: Caterpillar 3400 series engines

-

Benefit: Essential for efficient ignition and combustion stability

Injector Adaptor Components

Adaptor Nozzles

Adaptor nozzles allow precise fuel injection into each combustion chamber. They are critical for maintaining spray pattern accuracy and combustion efficiency.

-

Applications: Caterpillar 3408C, 3412, and 3412C engines

-

Benefit: Ensures consistent fuel atomization and efficient burn

O-Ring Seals for Adaptor Nozzles

High-pressure O-rings seal injector adaptor nozzles, preventing leaks and maintaining stable fuel delivery.

-

Applications: Caterpillar 3412 and 3412C

-

Benefit: Low-cost but vital—seals prevent fuel dilution and misfires

Push Rods, Lifters, and Valve Train Support

Push Rods

Push rods transfer camshaft motion to the rocker arms, ensuring accurate valve actuation.

-

Applications: Caterpillar 3406, 3408, and 3412

-

Benefit: Precision-machined for durability and smooth operation

Valve Lifters (Tappets)

Valve lifters maintain contact between the camshaft and push rods, ensuring smooth motion transfer.

-

Applications: Caterpillar 3406, 3408, and 3412

-

Benefit: Reduces wear, improves timing stability, and prevents valve train noise

Why Choose Diesel Pro Power for Caterpillar 3412C Cylinder Head Parts

When investing in cylinder heads or related top-end components for your Caterpillar 3412C, the supplier you choose matters just as much as the quality of the part itself. A cylinder head is one of the most critical components of the engine, and downtime caused by poor-quality replacements or delayed shipping can cost thousands in lost productivity. Diesel Pro Power eliminates these risks by providing unmatched support, fast fulfillment, and a customer-first approach.

-

Global Shipping Network

Diesel Pro Power ships to more than 180 countries, ensuring your Caterpillar 3412C parts arrive quickly no matter where your operation is located. From commercial shipping fleets to offshore rigs and remote power plants, we keep your equipment running by reducing downtime through reliable delivery. -

Proven Customer Trust

More than 40,000 satisfied customers worldwide depend on Diesel Pro Power. This proven track record means you’re partnering with a supplier trusted across industries where failure is not an option—marine, oil and gas, construction, and power generation. -

Comprehensive Parts Coverage

Every part you need for a 3412C cylinder head rebuild is available in one place. From complete assembled heads to bare castings, gasket sets, bolts, valves, springs, and even small hardware like locks and oil shields, Diesel Pro Power provides the full catalog in one streamlined source. -

Marine & Industrial Specialization

Unlike general automotive suppliers, Diesel Pro Power focuses exclusively on continuous-duty Caterpillar engines used in marine and industrial applications. This specialization ensures that the cylinder head parts you purchase are engineered for heavy workloads, long service intervals, and extreme operating environments. -

Expert Technical Support

Choosing the right cylinder head or gasket set requires knowledge of arrangement numbers, serial prefixes, and application details. Diesel Pro Power’s team of specialists is here to guide you, ensuring the correct fit the first time. Our expertise helps prevent costly mistakes and maximizes uptime for your Caterpillar 3412C engine.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588