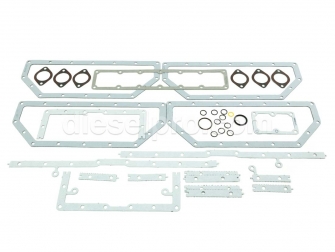

Parts for Caterpillar 3412E - Gasket Section

Loading...

Loading... Parts for Caterpillar 3412E – Gasket Section

The Caterpillar 3412E engine is a powerhouse widely used in heavy-duty applications such as marine propulsion, power generation, oilfield operations, and industrial machinery. To keep such an engine operating at peak performance, sealing components are critical. Gaskets and seals provide the airtight and fluid-tight barriers necessary to prevent leaks, maintain compression, and ensure long service life.

This section covers all major gasket solutions available for the Caterpillar 3412E engine, including full overhaul gasket sets, in-frame repair kits, cylinder head gasket sets, individual seals, and specialty gaskets for key components like the turbocharger, exhaust manifold, and oil pan.

Importance of Gaskets in the Caterpillar 3412E

Gaskets may seem like small components compared to cylinder heads or pistons, but they play one of the most vital roles in engine operation. On the Caterpillar 3412E:

-

Sealing High-Pressure Zones: Cylinder head gaskets and liner seals must withstand the extreme pressures and temperatures of combustion.

-

Preventing Oil & Coolant Leaks: Oil pan gaskets, crankshaft seals, and expansion tank gaskets maintain fluid integrity under continuous operation.

-

Maintaining Airflow Integrity: Turbocharger, intake, and exhaust gaskets ensure the correct delivery of pressurized air without leaks.

-

Supporting Longevity: Quality gasket materials reduce wear on mating surfaces and extend engine service life.

When it comes to overhauls, in-frame rebuilds, or even small repairs, choosing the correct gasket is essential to keeping the Caterpillar 3412E reliable.

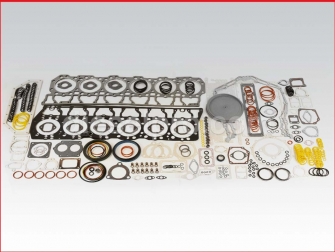

Overhaul Gasket Set for Caterpillar 3412E Engines

A complete overhaul gasket set is essential when performing a major rebuild of the 3412E engine. This comprehensive kit includes all major gaskets, O-rings, seals, and related components needed to disassemble and reassemble the engine from the block up.

-

Coverage for Major Components: Includes gaskets for cylinder heads, liners, intake and exhaust manifolds, oil pan, front and rear crankshaft seals, and more.

-

Designed for Full Engine Rebuilds: Ideal when the engine is stripped completely for overhaul, ensuring every sealing point is refreshed.

-

Serial-Specific Fit: These sets are designed for Caterpillar 3412E serial number ranges such as 9KS and 9PW, guaranteeing a proper match to engine variations.

Using a full overhaul gasket set not only saves time by bundling all required seals together but also eliminates the risk of missing critical components during a rebuild.

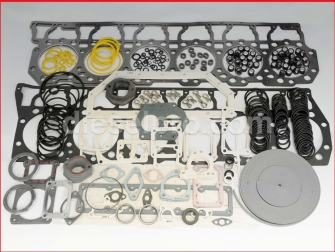

Gasket Set for In-Frame Repair

An in-frame repair gasket set is tailored for maintenance where the engine remains installed in equipment, vessel, or generator. Instead of a complete teardown, an in-frame set covers components that can be accessed and replaced without removing the entire engine block.

-

Includes Cylinder Head, Liner, and Oil Seals: Perfect for repairs where compression, coolant, or oil leaks are a concern.

-

Keeps Downtime Low: By allowing partial repairs, operators can get the engine back in service faster.

-

Compatible with Multiple Variants: The in-frame gasket set supports the Caterpillar 3412 as well as 3412B, 3412C, and certain 3412E variants.

These sets are frequently used in fleet operations, marine applications, and power generation facilities where downtime is costly.

Cylinder Head Gasket Set

The cylinder head gasket set is one of the most critical sealing packages for the Caterpillar 3412E. Designed to cover two heads per engine, this set includes the head gaskets and related sealing components necessary to maintain combustion pressure and prevent coolant or oil leaks.

-

Ensures Compression Integrity: Head gaskets seal the combustion chamber, preventing gas leakage during high-pressure firing cycles.

-

Prevents Coolant and Oil Mixing: Protects the engine from catastrophic failures caused by fluid contamination.

-

Designed for Dual-Head Systems: Since the 3412 series uses two heads, the set provides coverage for the complete engine.

Replacing head gaskets is essential during top-end rebuilds, cylinder head replacements, or whenever overheating or gasket failure occurs.

Cylinder Liner Seal Kit

Cylinder liners in the Caterpillar 3412E rely on precision sealing to prevent coolant leakage into the combustion chamber and crankcase. The liner seal kit provides O-rings and seals for each individual liner.

-

One Kit per Liner: Operators must purchase multiple kits when replacing several or all liners.

-

Maintains Coolant Control: Prevents cross-contamination between coolant and lubricating oil.

-

Durable Materials: Designed to withstand the constant heat cycles of heavy-duty operations.

These seals are critical during major overhauls and liner replacement jobs.

Expansion Tank Gasket Set

The expansion tank gasket set for the Caterpillar 3412E ensures that the cooling system maintains proper pressure and coolant flow.

-

Seals Expansion Tank to Housing: Prevents leaks from the coolant reservoir.

-

Maintains System Pressure: Ensures consistent cooling efficiency, especially in high-demand marine and power generation applications.

-

Compatible with Multiple Models: Works for both 3408 and 3412 engines.

A failing expansion tank gasket can result in coolant loss, overheating, and engine performance issues.

Aftercooler Gasket

The Caterpillar 3412E relies on its aftercooler system to reduce intake air temperatures after turbocharging, improving efficiency and power. The aftercooler gasket ensures no leakage of pressurized air or coolant at the joint.

-

Air-Tight Seal: Maintains boost pressure and airflow integrity.

-

Temperature Resistant: Designed for high-heat conditions typical of aftercoolers.

-

Critical for Turbocharged Engines: Prevents loss of performance and protects the combustion process.

Air Compressor Gasket

The air compressor gasket is a small but critical component for Caterpillar 3412E engines equipped with auxiliary air compression systems.

-

Prevents Air Leaks: Ensures proper functioning of the compressor for starting systems or auxiliary equipment.

-

Supports Accessory Reliability: Air compressors often power essential onboard systems in marine or industrial setups.

-

Durable Design: Built to withstand continuous vibration and thermal cycles.

Exhaust Manifold Gasket

The exhaust manifold gasket creates a seal between the engine block and the manifold, ensuring exhaust gases flow efficiently into the turbocharger or exhaust piping.

-

Heat Resistant: Withstands extreme exhaust temperatures.

-

Prevents Gas Leakage: Protects operators from fumes and prevents performance loss.

-

Critical for Turbocharging: Maintains exhaust pressure required for turbocharger operation.

Flywheel Housing Gasket

The flywheel housing gasket seals the flywheel cover to the engine block. Though less noticeable than head or liner gaskets, it plays an important role in protecting internal components.

-

Prevents Oil Leakage: Ensures the rear of the block remains sealed against oil seepage.

-

Supports Proper Alignment: A good seal ensures the flywheel housing stays correctly aligned with the transmission.

-

Durable Under Stress: Designed to withstand torsional vibration and continuous stress.

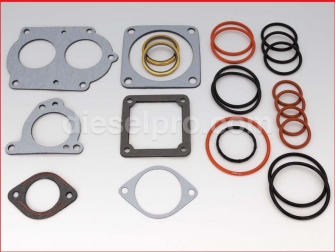

Turbocharger Gasket

The Caterpillar 3412E turbo system requires precision sealing to prevent leaks in both exhaust and intake paths. Turbocharger gaskets ensure reliable airflow and pressure.

-

One Per Turbo: Each turbo requires its own dedicated gasket.

-

High Heat Resistance: Built for extreme exhaust gas temperatures.

-

Protects Turbo Performance: Ensures the turbo operates at peak efficiency without pressure loss.

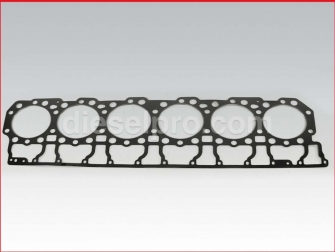

Head Gasket

The individual head gasket for the Caterpillar 3412E provides sealing for each head, and two are required per engine.

-

Supports Combustion Efficiency: Maintains the pressure needed for complete combustion.

-

Prevents Leaks: Stops coolant and oil leaks between the block and head.

-

Critical During Rebuilds: Always replaced during cylinder head installation or major overhauls.

Oil Pan Gasket

The oil pan gasket seals the joint between the oil pan and the bottom of the engine block.

-

Prevents Oil Leaks: Ensures lubrication remains within the system.

-

Maintains Crankcase Integrity: Helps keep contaminants out of the oil system.

-

Durable Construction: Designed to handle vibration and oil exposure over long service intervals.

Crankshaft Seals (Front and Rear)

The front and rear crankshaft seals are among the most critical gaskets for preventing oil leakage at the rotating ends of the crankshaft.

-

Front Crankshaft Seal: Protects the timing cover area and accessory drive from leaks.

-

Rear Crankshaft Seal: Prevents oil seepage where the crankshaft meets the flywheel housing.

-

Vital for Engine Longevity: Leaking crank seals can quickly lead to oil loss and bearing damage.

Why Buy Caterpillar 3412E Gaskets from Diesel Pro Power

Trusted by 40,000+ Customers Worldwide

Diesel Pro Power serves operators in more than 180 countries, supplying fleets, shipyards, power plants, and industrial facilities with reliable gasket solutions.

Fast Global Shipping

Every order ships within 24 hours and includes real-time tracking, helping operators minimize downtime.

Engine-Specific Catalogs

Unlike generic suppliers, Diesel Pro Power organizes parts by engine model. Caterpillar 3412E owners can find the exact gasket sets and seals they need without confusion.

Premium Quality Components

All gasket kits and seals meet or exceed OEM standards, ensuring long-lasting durability under the harshest operating conditions.

Expert Technical Support

From identifying the right gasket set to installation guidance, Diesel Pro Power provides direct support backed by decades of Caterpillar experience.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588