Cummins 6C Engine Parts - Cylinder Head Section

Loading...

Loading... Cylinder Heads & Related Components For Cummins 6C Engines

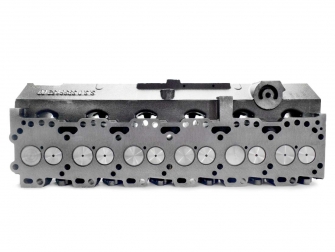

The Cummins 6C engine family—including the 6C8.3, 6CT8.3, and 6CTA8.3—has earned a reputation for reliable power delivery in a wide range of industrial, commercial, and marine applications. The cylinder head plays a critical role in maintaining engine performance, efficiency, and emissions compliance. At Diesel Pro Power, we carry a comprehensive selection of brand-new cylinder heads and all related components for the 6C series to help you get your engine back in peak operating condition.

New Cylinder Heads for Cummins 6C, 6CT, and 6CTA 8.3 Engines

We offer multiple configurations of new cylinder heads for the Cummins 6C engine platform:

-

New Head with Valves – 16” Air Intake (Non-Marine): This version is ideal for land-based equipment where the intake configuration requires a more compact fit.

-

New Head with Valves – 21” Air Intake (Non-Marine): Designed for larger industrial applications needing increased airflow and a higher intake profile.

-

New Head with Valves – 21” Air Intake (Marine): Specially manufactured for marine-grade requirements with corrosion-resistant treatments and materials suited for saltwater environments.

Each cylinder head comes complete with pre-installed valves to reduce rebuild time and ensure proper valve seating from the start.

Intake & Exhaust Valves

The intake and exhaust valves in your Cummins 6C engine are responsible for regulating airflow and combustion gases in and out of the cylinder head. If these valves are worn, damaged, or improperly seated, the engine’s performance and emissions can be drastically affected.

-

Intake Valves: Precision-engineered for optimal fit, air seal, and thermal resistance.

-

Exhaust Valves: Manufactured to withstand the higher heat loads from exhaust gases. Often paired with valve rotators for extended life.

All valves are compatible with both standard and marine-grade cylinder heads in the 6C, 6CT, and 6CTA configurations.

Valve Train Components

To keep your valvetrain in top shape, we provide all necessary supporting components engineered to OE standards or better:

Valve Springs

Each intake and exhaust valve requires a high-strength spring to maintain seating pressure. We offer:

-

Standard Intake Valve Springs

-

Exhaust Valve Springs with Rotator Compatibility

Springs should always be replaced if any fatigue, cracks, or wear are present.

Valve Rotators

Valve rotators are used on the exhaust side to prevent hot spots and valve seat erosion. If you’re replacing exhaust valves, it’s a good practice to replace the rotators as well.

Valve Spring Retainers & Keepers

Essential for securing the springs in place, these components must withstand high-frequency motion and heat. Always inspect for cracks, warping, or wear before reuse.

Cylinder Head Fastening Hardware

Reassembling your 6C head properly starts with the right hardware.

Cylinder Head Bolts

We offer two types of cylinder head bolts:

Torque-to-yield specifications should always be followed when installing new bolts. Do not reuse old bolts, as they may have stretched beyond spec.

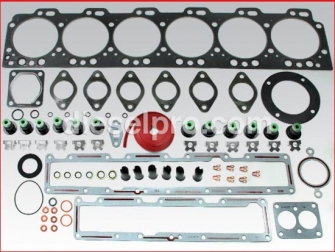

Gaskets & Sealing Components

Proper sealing is critical for maintaining compression and preventing coolant or oil leaks.

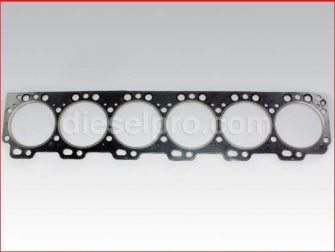

Head Gaskets

We carry head gaskets designed specifically for Cummins 6C and 6CT engines, with variations for different horsepower ratings:

Gasket kits include critical sealing surfaces for the head, intake, exhaust, and valve covers.

Valve Cover Gaskets

Manufactured to maintain an oil-tight seal, these gaskets are essential when performing any head work or replacing valve train components.

Intake Connection Gaskets

These gaskets ensure airtight intake manifold to head sealing—important for maintaining turbo boost pressure and preventing air leaks.

Gear Cover & Gear Housing Gaskets

Engine timing gear enclosures require specialized gaskets to prevent oil leakage. These should always be replaced if the gear cover is removed during head service.

Valve Guides & Inserts

Worn guides can cause valve stem wobble, increased oil consumption, and premature valve failure. We offer:

-

Standard Valve Guides

Oversized valve inserts are commonly used during head refurbishments to restore valve seat height and sealing surfaces.

Valve Stem Seals (Steam Valve Seals)

Valve stem seals control oil flow to the valve guides. Worn seals can cause oil burning, smoke, and carbon buildup. We carry seals manufactured from high-temperature elastomers for extended durability in high-heat applications.

Push Rods & Rocker Arm Hardware

Replacing worn push rods is critical in any head service job, especially when bent or oil passageways are blocked.

-

Push Rods for 6C, 6CT, and 6CTA Engines: Ensure precise valve timing and oil transfer to rocker assemblies.

-

Heavy Hexagon Nuts: Used in the rocker arm assembly to provide secure adjustments.

Temperature Switches (Compatible Applications)

We also offer temperature switches compatible with Cummins and Detroit Diesel engines, closing at 205°F and designed with a 1/2" NPT thread size. These are often replaced during top-end rebuilds or cylinder head servicing to ensure accurate engine temperature monitoring.

Marine vs. Non-Marine Cylinder Heads

Differences in Configuration

-

Non-Marine Cylinder Heads:

-

Available with 16” or 21” air intake ports.

-

Optimized for industrial or on-highway applications.

-

Typically do not require corrosion-resistant coatings.

-

Marine Cylinder Heads:

-

Built with special materials and coatings to resist saltwater corrosion.

-

Feature marine-specific port alignments and hardware configurations.

-

Often paired with EGR or turbo modifications unique to marine duty cycles.

Be sure to select the correct cylinder head based on your application—marine engines should never use non-marine heads, as longevity and reliability will be compromised.

Cylinder Head Maintenance Tips for Cummins 6C Series

-

Always follow OEM torque specs and bolt tightening sequences.

-

Replace all sealing components during a head swap—especially the head gasket and intake/exhaust manifold gaskets.

-

Inspect all valve components for wear, including valves, springs, seals, guides, and rotators.

-

Flush the cooling system to prevent contamination of the new head.

-

Verify push rods and rocker components for straightness and surface integrity.

Why Buy Your 6C Cylinder Head Parts from Diesel Pro Power?

With over 40,000 satisfied customers worldwide, Diesel Pro Power is your trusted partner for Cummins engine rebuild parts. We stock only quality-assured components for long-term reliability and performance, including:

-

Brand-new cylinder heads ready to install

-

Precision-engineered valve components

-

OEM-quality gaskets and seals

-

Fast shipping and in-stock availability

We also provide technical guidance and personalized support so you can order with confidence.

Common Applications for the Cummins 6C, 6CT, and 6CTA Engines

-

Agricultural Equipment (tractors, harvesters)

-

Marine Propulsion and Generator Sets

-

Industrial Machinery

-

Construction Equipment

-

Emergency Standby Generators

-

Water Pumps and Irrigation Systems

These engines are known for their robustness, simplicity, and long service life—which is why investing in proper top-end service with a quality cylinder head is critical to extending their usable lifespan.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588