Cummins 6B Engine Parts - Engine Overhaul Kit Section

Loading...

Loading... -

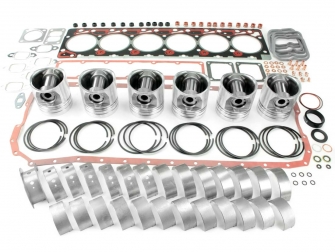

Cummins Rebuild Kit for 6B, 6BT, 6BTA - 17.5:1 compression ratio

IFK2160-6B

For engines with CPL #s 597, 692, 712, 716, 729, 761, 804, 807, 856, 938, 943, 947, 948, 949, 950, 970, 971, 994, 1160, 1163, 1168, 1189, 1207, 1245, 1246, 1266, 1279, 1288, 1289, 1440, 1554, 1601, 1627, 1685, 2049, 2413

Price: $ 776.09 -

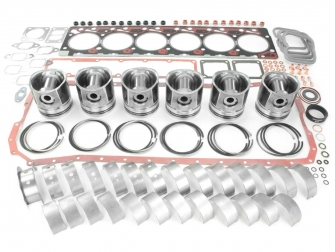

Cummins Rebuild Kit for 6B, 6BT, 6BTA

IFK2747-6B

For engines with CPL #s 1071, 1902, 1948, 1961, 1962, 2014, 2015, 2016, 2071, 2122, 2125, 2242, 2292, 2296, 2372, 2373, 2417, 2551, 2868, 3868, 8444

Price: $ 682.32 -

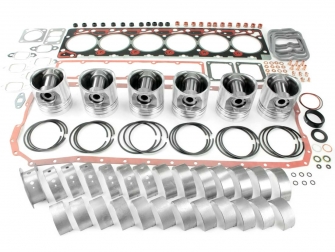

Cummins Rebuild Kit for 6B, 6BT, 6BTA

IFK2561-6B

For engines with CPL #s 1551, 1552, 1553, 1744, 1914, 1915, 1916, 2000, 2013, 2023, 2175, 2243, 2249, 2252, 2253, 2347, 2348, 2375, 3219

Price: $ 669.36 -

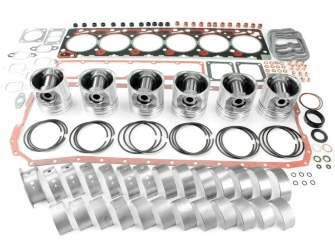

Cummins Rebuild Kit 6B, 6BT, 6BTA - 15.3:1 compression ratio

IFK0756-6B

For engines with CPL #s 1975, 2205, 2208, 2956, 8457

Price: $ 882.76 -

Cummins Rebuild Kit for 6B, 6BT, 6BTA - 16.5:1 compression ratio

IFK2100-6B

For engines with CPL #s 599, 600, 698, 713, 715, 742, 792, 834, 912, 940, 961, 962, 983, 998, 1174, 1209, 1518, 1523, 1524, 1581, 2050, 2530, 2891, 8206.

Price: $ 699.13 -

Cummins Rebuild Kit for 6B, 6BT, 6BTA - 17.3:1 compression ratio

IFK2060-6B

For engines with CPL #s 596, 691, 714, 791, 802, 845, 960, 999, 1320, 1403, 1433, 1608

Price: $ 661.50 -

Cummins Rebuild Kit for 6B, 6BT, 6BTA - 17.5:1 compression ratio

IFK2170-6B

For engines with CPL #s 953, 970, 1165, 1247, 1313, 1322, 1408, 1570, 1613, 1638, 1928

Price: $ 697.28 -

Nozzle to cool pistons for Cummins B, BT, BTA, ISB and QSB

4937308

Requires one per piston

Price: $ 11.65 -

Cummins Salvage Sleeve - Standard

3904166

Liner to repair or return block to standard sizePrice: $ 40.05 -

-

-

-

-

Cummins Fuel Filter & Water Separator

3286503

3.02" diameter, 5.62" height, thread: M16 x 1.5" - 6H INTPrice: $ 44.78 -

-

Cummins Oil Filter

3908616

Spin-on type. 3.66" outside diameter, 5.35" height, thread size: 1-16 UNPrice: $ 25.74 -

-

Oil Filter Removal Wrench for Detroit Diesel, Caterpillar & Cummins

2321

4-21/32" to 5-5/32"Price: $ 63.29 -

-

Temperature switch for Detroit Diesel, Cummins, Caterpillar engines

5146080

Closes at 205 degrees Fahrenheit.Thread size is 1/2 NPTPrice: $ 97.19 -

Cummins 6B Overhaul Kits – Reliable Rebuild Solutions for Naturally Aspirated Engines

Diesel Pro Power offers CPL-matched overhaul kits specifically designed for the Cummins 6B, a naturally aspirated variant of the B Series engine family. Renowned for its simplicity, mechanical durability, and long operational life, the 6B engine remains a workhorse in industrial, agricultural, and marine auxiliary settings.

Whether you’re restoring a 6B engine for stationary power generation, irrigation duty, construction equipment, or marine support roles, our complete engine rebuild kits and accessories are trusted by over 40,000 Diesel Pro Power customers around the world.

Cummins 6B Engine Overview

The Cummins 6B is a 5.9-liter inline 6-cylinder naturally aspirated diesel engine. It shares the robust mechanical platform of the 6BT and 6BTA engines but lacks forced induction. This simplicity makes the 6B particularly desirable for low-maintenance, low-speed, high-torque applications.

Key Specs:

-

Engine Type: Inline 6-cylinder, naturally aspirated

-

Displacement: 5.9L (359 cu. in.)

-

Fuel System: Mechanical direct injection

-

Induction: Naturally aspirated (no turbocharger)

-

Applications: Agricultural pumps, generators, off-road equipment, marine auxiliaries

The 6B’s minimal electronics and durable cast-iron construction make it a favorite in harsh environments where reliability is paramount.

When to Rebuild a Cummins 6B Engine

Over time, even the most reliable 6B engines require overhaul. Common signs of rebuild necessity include:

-

Loss of compression or power

-

Excessive blow-by

-

Increased oil or fuel consumption

-

Difficult cold starting

-

White, blue, or black exhaust smoke

-

Internal coolant leaks or overheating

A full rebuild can restore original performance and prolong service life by thousands of hours when done with the correct CPL-matched components.

What’s Included in a Cummins 6B Overhaul Kit?

Each Diesel Pro Power 6B rebuild kit contains:

-

Pistons matched to CPL compression ratio

-

Piston rings and wrist pins

-

Cylinder liners

-

Main and rod bearings

-

Complete upper and lower gasket sets

-

Crankshaft front and rear seals

All kits are based on OEM CPL specifications to guarantee compatibility with your engine block, piston bowl shape, and injection timing.

CPL Number Compatibility – Choose the Right Overhaul Kit

Diesel Pro Power offers several Cummins 6B rebuild kits based on CPL numbers and compression ratio:

Overhaul Kit for Cummins 6B – Compatible with CPL Numbers:

597, 692, 712, 716, 729, 761, 804, 807, 856, 938, 943, 947, 948, 949, 950, 970, 971, 994, 1160, 1163, 1168, 1189, 1207, 1245, 1246, 1266, 1279, 1288, 1289, 1440, 1554, 1601, 1627, 1685, 2049, 2413

-

Compression Ratio: 17.5:1

Overhaul Kit for Cummins 6B – Compatible with CPL Numbers:

1071, 1902, 1948, 1961, 1962, 2014, 2015, 2016, 2071, 2122, 2125, 2242, 2292, 2296, 2372, 2373, 2417, 2551, 2868, 3868, 8444

Overhaul Kit for Cummins 6B – Compatible with CPL Numbers:

1551, 1552, 1553, 1744, 1914, 1915, 1916, 2000, 2013, 2023, 2175, 2243, 2249, 2252, 2253, 2347, 2348, 2375, 3219

-

Compression Ratio: 15.3:1

Overhaul Kit for Cummins 6B – Compatible with CPL Numbers:

1975, 2205, 2208, 2956, 8457

-

Compression Ratio: 15.3:1

Overhaul Kit for Cummins 6B – Compatible with CPL Numbers:

599, 600, 698, 713, 715, 742, 792, 834, 912, 940, 961, 962, 983, 998, 1174, 1209, 1518, 1523, 1524, 1581, 2050, 2530, 2891, 8206

-

Compression Ratio: 16.5:1

Overhaul Kit for Cummins 6B – Compatible with CPL Numbers:

596, 691, 714, 791, 802, 845, 960, 999, 1320, 1403, 1433, 1608

-

Compression Ratio: 17.3:1

Overhaul Kit for Cummins 6B – Compatible with CPL Numbers:

953, 970, 1165, 1247, 1313, 1322, 1408, 1570, 1613, 1638, 1928

-

Compression Ratio: 17.5:1

Matching Compression Ratio to Application

Compression Ratio Guidelines:

-

15.3:1 – Lower compression for emissions-tuned or light-duty builds

-

16.5:1 – Standard industrial duty and balanced torque applications

-

17.3:1 – High-efficiency fuel configurations

-

17.5:1 – Heavy-duty operation and cold-start performance

Incorrect piston compression can result in hard starting, detonation, or reduced output. Always confirm CPL before ordering.

Complementary Components for a Complete Rebuild

Expansion Plug Kit

Seals block coolant passages. Includes core plugs for full reseal.

Salvage Sleeve (Standard)

Used to recondition blocks with excessive cylinder wear.

Crankshaft Seal Kit – Front

Includes seal and dust cover. Prevents leaks at front cover.

Piston Cooling Nozzles

Spray oil to underside of pistons for improved heat dissipation. One per cylinder.

Post-Rebuild Maintenance and Filters

Oil Filter

Protects engine during critical break-in period.

Fuel Filter

Shields injectors from contaminants in new fuel system.

Fuel/Water Separator

Protects injection system from corrosion or cavitation damage.

Essential Tools for 6B Engine Rebuilds

-

Feeler Gauge – For precise valve lash setting

-

Piston Ring Installer – Prevents damage to new rings

-

Fuel Filter Wrench – Makes servicing easier

-

Oil Filter Wrench – Sized for Cummins filter housings

Cooling System Add-Ons

-

Radiator Cleaner – Removes rust and scale from internal coolant passages

-

Temperature Switch (205°F) – Activates fan or alarm circuits in overheating conditions

Monitoring Gauges

-

Oil Pressure, Coolant Temperature, Gauges with Alarms

Post-rebuild monitoring is essential to engine longevity.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588