Repuestos para Cummins 6BTA - Sección Conjunto de Reparación

Loading...

Loading... -

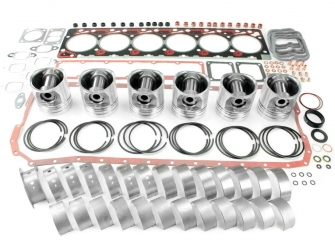

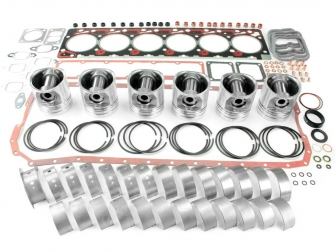

Cummins Conjunto de Reparacion motores 6B, 6BT, 6BTA, 17.5:1 relación de compresión

IFK2160-6B

Para motores con CPL #s 597, 692, 712, 716, 729, 761, 804, 807, 856, 938, 943, 947, 948, 949, 950, 970, 971, 994, 1160, 1163, 1168, 1189, 1207, 1245, 1246, 1266, 1279, 1288, 1289, 1440, 1554, 1601, 1627, 1685, 2049, 2413

Precio: $ 813,77 -

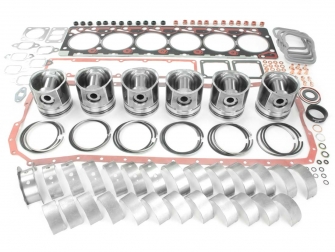

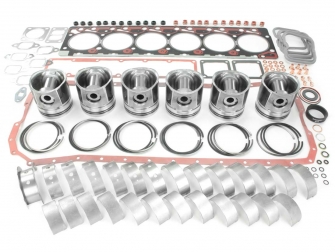

Cummins Conjunto de Reparacion 6B, 6BT, 6BTA

IFK2747-6B

Para motores con CPL #s 1071, 1902, 1948, 1961, 1962, 2014, 2015, 2016, 2071, 2122, 2125, 2242, 2292, 2296, 2372, 2373, 2417, 2551, 2868, 84468

Precio: $ 713,58 -

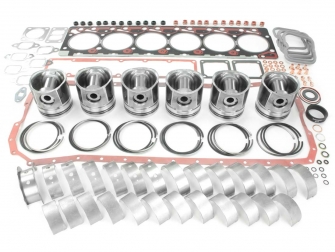

Cummins Conjunto de Reparacion para 6B, 6BT, 6BTA

IFK2561-6B

Para motores con CPL #s 1551, 1552, 1553, 1744, 1914, 1915, 1916, 2000, 2013, 2023, 2175, 2243, 2249, 2252, 2253, 2347, 2348, 2375, 3219

Precio: $ 700,62 -

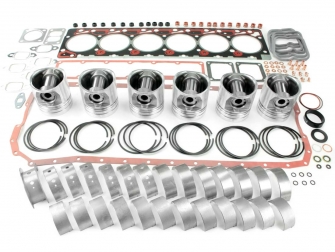

Cummins Conjunto de Reparacion 6B, 6BT, 6BTA, 15.3:1 relación de compresión

IFK0756-6B

Para motores con CPL #s 1975, 2205, 2208, 2956, 8457

Precio: $ 917,93 -

Cummins Conjunto de Reparacion 6B, 6BT, 6BTA, relación de compresión 16.5:1

IFK2100-6B

Para motores con CPL #s 599, 600, 698, 713, 715, 742, 792, 834, 912, 940, 961, 962, 983, 998, 1174, 1209, 1518, 1523, 1524, 1581, 2050, 2530, 2891, 8206.

Precio: $ 733,07 -

Cummins Conjunto de Reparacion 6B, 6BT, 6BTA, 17.3:1 relación de compresión

IFK2060-6B

Para motores con CPL #s 596, 691, 714, 791, 802, 845, 960, 999, 1320, 1403, 1433, 1608

Precio: $ 694,20 -

Cummins Conjunto de Reparacion 6B, 6BT, 6BTA, 17.5:1 relación de compresión

IFK2170-6B

Para motores con CPL #s 953, 970, 1165, 1247, 1313, 1322, 1408, 1570, 1613, 1638, 1928

Precio: $ 729,98 -

Boquilla para enfriar pistones para Cummins B, BT, BTA, ISB y QSB

4937308

Requiere uno por pistón

Precio: $ 11,65 -

Cummins Camisa estándar

3904166

Camisa para reparar el bloque y retornarlo a tamaño estándarPrecio: $ 40,05 -

Cummins Conjunto de Sello Delantero para Cigüeñal

3937111

Incluye el sello y el guardapolvoPrecio: $ 25,46 -

-

-

Cummins Filtro de combustible

4990879

2,813" de diámetro, 4,57" de altura, rosca: M16 x 1,5" - 6Precio: $ 29,02 -

Cummins Filtro de combustible y separador de agua

3286503

3,02" de diámetro, 5,62" de altura, rosca: M16 x 1,5" - 6H INTPrecio: $ 44,78 -

Herramienta para ensamblar aro de piston

J8128

Para motores Detroit Diesel y CumminsPrecio: $ 65,10 -

Cummins Filtro de aceite

3908616

Tipo giratorio. Diámetro exterior de 3,66", altura de 5,35", tamaño de rosca: 1-16 UNPrecio: $ 25,74 -

Llave para quitar el filtro de combustible de Detroit Diesel y Cummins

190

3-7/16" a 3-3/4"Precio: $ 14,50 -

Llave para remover filtro de aceite para Detroit Diesel, Caterpillar y Cummins

2321

4-21/32" a 5-5/32"Precio: $ 63,29 -

Limpiador de radiador

18E

Solo disponibles para venta con envios terrestres dentro USA y CanadaPrecio: $ 37,51 -

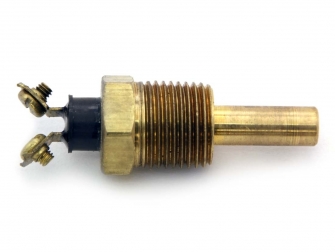

Switch de temperatura para Detroit Diesel, Cummins, Caterpillar

5146080

Cierra a 205 grados Fahrenheit.El tamaño de la rosca es 1/2 NPTPrecio: $ 97,19 -

Cummins 6BTA Overhaul Kits – Complete Rebuild Kits by CPL and Compression Ratio

The Cummins 6BTA engine is a turbocharged powerhouse known for its balance of performance and efficiency across marine and industrial applications. When your 6BTA shows signs of wear — like excessive blow-by, smoke on startup, loss of power, or declining compression — it’s time to consider a full rebuild using a kit that precisely matches your engine’s CPL and compression ratio.

At Diesel Pro Power, we carry premium-quality overhaul kits for the Cummins 6BTA, organized by CPL and compression ratio for direct fitment. These kits include pistons, liners, bearings, and full gasket sets to restore your engine to original factory condition or better.

With more than 40,000 satisfied customers worldwide and a catalog purpose-built for marine and industrial diesel power, Diesel Pro Power is your most reliable source for Cummins 6BTA engine rebuild solutions.

Engine Specifications & Applications – Cummins 6BTA

-

Configuration: 6-cylinder inline diesel

-

Displacement: 5.9 liters (359 cubic inches)

-

Bore x Stroke: 102 mm x 120 mm

-

Cycle: 4-stroke

-

Aspiration: Turbocharged, aftercooled (intercooled)

-

Fuel System: Direct injection, rotary or inline mechanical pump

-

Compression Ratios Common to the 6BTA: 15.3:1, 16.5:1, 17.3:1, 17.5:1

-

Applications:

-

Marine propulsion and generator sets

-

Stationary industrial power units

-

Hydraulic drive systems and pump stations

-

Agricultural irrigation systems

-

Overhaul Kits for Cummins 6BTA by CPL Number and Compression Ratio

Diesel Pro Power matches each 6BTA overhaul kit to specific CPL (Control Parts List) numbers. CPL matching ensures piston design, compression height, combustion chamber profile, and liner fitment align with Cummins factory specs.

Rebuild Kit – 17.5:1 Compression Ratio

Compatible CPL Numbers: 597, 692, 712, 716, 729, 761, 804, 807, 856, 938, 943, 947, 948, 949, 950, 970, 971, 994, 1160, 1163, 1168, 1189, 1207, 1245, 1246, 1266, 1279, 1288, 1289, 1440, 1554, 1601, 1627, 1685, 2049, 2413

This high-compression kit provides fast ignition timing and strong torque under load — ideal for standard marine and industrial 6BTA builds operating in cooler environments.

Rebuild Kit – 17.5:1 Compression Ratio

Compatible CPL Numbers: 953, 970, 1165, 1247, 1313, 1322, 1408, 1570, 1613, 1638, 1928

Includes pistons and liner profiles matched for CPLs with more recent piston cooling nozzle designs and exhaust backpressure tuning.

Rebuild Kit – 17.3:1 Compression Ratio

Compatible CPL Numbers: 596, 691, 714, 791, 802, 845, 960, 999, 1320, 1403, 1433, 1608

Slightly reduced compression allows for better thermal management in high-load or turbocharged marine auxiliary engines.

Rebuild Kit – 16.5:1 Compression Ratio

Compatible CPL Numbers: 599, 600, 698, 713, 715, 742, 792, 834, 912, 940, 961, 962, 983, 998, 1174, 1209, 1518, 1523, 1524, 1581, 2050, 2530, 2891, 8206

Often used in hot-climate applications or when running extended RPM ranges under load. Lower combustion temperature reduces engine stress.

Rebuild Kit – 15.3:1 Compression Ratio

Compatible CPL Numbers: 1551, 1552, 1553, 1744, 1914, 1915, 1916, 2000, 2013, 2023, 2175, 2243, 2249, 2252, 2253, 2347, 2348, 2375, 3219

Also Available For: CPL Numbers 1975, 2205, 2208, 2956, 8457

These ultra-low compression kits are designed for extreme-duty applications using high boost pressure or continuous full-load operation. Helps reduce wear in turbocharged engines where cylinder pressure is consistently elevated.

Rebuild Kit – Standard Compression Ratio

Compatible CPL Numbers: 1071, 1902, 1948, 1961, 1962, 2014, 2015, 2016, 2071, 2122, 2125, 2242, 2292, 2296, 2372, 2373, 2417, 2551, 2868, 3868, 8444

These kits cover many popular 6BTA generator and propulsion engine configurations, especially those used in marine auxiliary power units and vessel hydraulics.

Understanding Compression Ratios in Cummins 6BTA Engines

Compression ratio refers to the difference in cylinder volume from bottom dead center (BDC) to top dead center (TDC). Diesel engines rely entirely on compression heat to ignite the fuel-air mixture. That’s why getting this number right is critical.

-

17.5:1 – Fast ignition and high torque, best for standard duty

-

17.3:1 – Ideal for sustained load use with less thermal strain

-

16.5:1 – Better for high-temp environments or heavy fuel loads

-

15.3:1 – Designed for high-boost builds or constant full-load marine service

Always rebuild using the same compression ratio your CPL was built for. Changing it can result in pre-ignition, valve interference, or reduced fuel economy.

Additional Components to Support Your 6BTA Rebuild

Diesel Pro Power stocks all supporting components needed for a complete rebuild of your Cummins 6BTA:

Piston Cooling Nozzles

Required on most turbocharged 6BTA engines. These nozzles spray oil onto the underside of each piston to prevent heat damage during sustained combustion. Replace one per cylinder during overhaul.

Salvage Sleeves

Standard sleeves allow for reuse of blocks that have worn beyond liner spec. Our sleeves restore cylinder diameter and concentricity for proper piston fit.

Expansion Plug Kits

Essential for resealing coolant passages and oil galleries after machine work. Includes all freeze plugs needed for a full 6BTA rebuild.

Front and Rear Crankshaft Seals

Seal replacement is mandatory for leak-free operation. Kits include dust shields and press-in seals.

Service Filters and Maintenance Parts

No rebuild is complete without servicing the filters and primary consumables:

-

Oil Filters – Spin-on filters engineered to match 6BTA housing threads and flow spec

-

Fuel Filters & Water Separators – Protects new injectors and pump components

-

Gasket Sets – Full kits include cylinder head gaskets, intake/exhaust seals, oil pan seals, and valve cover gaskets

Tools Recommended for Cummins 6BTA Rebuilds

A quality rebuild is only as good as the tools used. Diesel Pro Power carries all core tools for servicing your 6BTA:

-

Feeler Gauge (.002"–.025") – For precise valve lash setting post-rebuild

-

Piston Ring Installation Tool – Protects rings from distortion during assembly

-

Fuel Filter Wrench – Helps install new filters without damage

-

Oil Filter Wrench – Ensures proper torque and seal compression

-

Radiator Cleaner – Clears sediment during coolant system prep

-

Temperature Switches – Replace aged sensors to prevent overheating

-

Gauges (Mechanical or Electric) – Available in 12V or 24V for RPM, oil pressure, or coolant temperature monitoring

Gratis a USA: 1-888-433-4735

Gratis a USA: 1-888-433-4735 Internacional: 305-545-5588

Internacional: 305-545-5588