Cummins ISL Parts

-Select Parts Category

Loading...

Loading... Cummins ISL Engine Parts Catalog – Complete Selection for Heavy-Duty Applications

Introduction to the Cummins ISL Engine

The Cummins ISL diesel engine delivers exceptional performance across on-highway and off-highway sectors. It’s widely used in trucks, buses, refuse vehicles, and construction equipment. While not marine-rated, its design emphasizes durability, torque, and fuel efficiency. This catalog provides a comprehensive selection of parts to keep your Cummins ISL running at peak performance.

Cummins ISL Engine Specifications

-

Configuration: Inline 6-cylinder

-

Displacement: 8.9L (8900 cc)

-

Power Output: 280–400 HP

-

Torque Output: Up to 1250 lb-ft

-

Compression Ratio: 16.6:1

-

Fuel System: High-Pressure Common Rail (HPCR)

-

Applications: Trucks, buses, refuse vehicles, construction equipment

Complete Cummins ISL Parts Catalog

Rebuild Kit and Related Components for Cummins ISL Engines

A complete rebuild restores your Cummins ISL engine to original performance standards. Our overhaul kits include pistons, rings, bearings, seals, and comprehensive gasket sets. Upper and lower gasket kits ensure a complete seal during rebuilds, while piston kits offer high-precision replacements. Restore reliability and efficiency with a full rebuild solution tailored to the ISL engine.

Gauges and Related Components for Cummins ISL Engines

Monitoring engine performance is critical for long-term durability. Our gauge selection includes oil pressure and temperature options, offered in both mechanical and electrical configurations. Each kit comes with the necessary installation fittings and mounting hardware. Accurate readings help prevent engine damage by providing early warnings of potential issues.

Engine Water Pump and Related Components for Cummins ISL Engines

A reliable water pump is essential for maintaining engine temperatures under load. Our ISL water pumps are engineered for high flow capacity, ensuring efficient coolant circulation. Gaskets and seals prevent leaks while thermostats and housings regulate temperature for optimal operation. Regular maintenance of the cooling system is key to avoiding costly overheating failures.

Cylinder Head and Related Components for Cummins ISL Engines

The cylinder head is a critical component influencing compression and valve operation. We offer complete cylinder heads, as well as replacement gaskets, valves, springs, and inserts for repair or rebuild projects. Designed to withstand high-pressure combustion, these components ensure long service life. Precision engineering guarantees reliable performance and a perfect fit for your ISL engine.

Fuel Pump and Related Components for Cummins ISL Engines

Fuel delivery is at the heart of engine efficiency and power. Our selection includes high-pressure fuel pumps, essential seals and gaskets, and durable fuel lines and connectors. These components work together to ensure precise fuel metering and consistent flow to injectors. Maintaining fuel system integrity is essential for peak ISL engine performance and fuel economy.

Turbo and Related Components for Cummins ISL Engines

Turbochargers increase power output and improve fuel efficiency in the ISL engine. We offer complete turbo assemblies, along with gaskets, seals, and intercooler hoses to maintain system integrity. Proper turbo operation ensures optimal air intake and exhaust flow management. Regular inspection and maintenance of these components help prevent costly turbo failures.

Oil System Components and Related Parts for Cummins ISL Engines

The oil system keeps engine components lubricated and cool, even under heavy load. We offer oil pumps, high-efficiency filters, coolers, and oil pan gaskets for complete system coverage. Pressure switches are available to monitor and control oil pressure. Maintaining a clean, well-lubricated oil system is vital to extending ISL engine life.

Crankshaft and Related Components for Cummins ISL Engines

The crankshaft converts linear piston motion into rotational energy. Precision-ground crankshafts, along with high-quality bearings, seals, and thrust washers, ensure smooth operation. These components are essential for minimizing friction and wear under high-load conditions. Proper crankshaft maintenance supports optimal engine performance and reliability.

Camshaft and Related Components for Cummins ISL Engines

Camshafts control valve timing and influence engine breathing efficiency. We offer replacement camshafts, bearings, bushings, and gear sets engineered for ISL engines. These components ensure synchronized operation between valves and pistons. High-quality cam components are critical for maintaining power and fuel efficiency.

Piston Kits and Related Components for Cummins ISL Engines

Pistons are central to combustion, transferring energy from fuel combustion to crankshaft motion. Our kits include pistons, rings, pins, and cooling jets designed for high durability. Precision manufacturing ensures proper fit and compression sealing. Regular piston inspection and replacement prevent power loss and oil blow-by issues.

Connecting Rods and Related Components for Cummins ISL Engines

Connecting rods link pistons to the crankshaft, transmitting force during combustion. Our rods are engineered for strength, with accompanying bearings and fasteners ensuring secure assembly. High-quality rods reduce the risk of engine knock or bearing failure. Routine inspection and replacement keep ISL engines running smoothly.

Exhaust System Components and Related Parts for Cummins ISL Engines

Efficient exhaust flow is essential for emissions control and engine performance. We offer exhaust manifolds, gaskets, mufflers, flanges, and insulation wraps. These components protect surrounding parts from heat and minimize backpressure. Well-maintained exhaust systems improve fuel efficiency and reduce environmental impact.

Gaskets and Related Seals for Cummins ISL Engines

Gaskets provide critical sealing between engine components. Our selection includes cylinder head gaskets, oil pan gaskets, exhaust manifold gaskets, and complete gasket sets. Quality gaskets prevent leaks and ensure system integrity. Using the correct gasket materials is crucial for long-lasting, leak-free operation.

Sensors and Related Components for Cummins ISL Engines

Accurate sensors enable precise engine control and diagnostics. We provide camshaft and crankshaft sensors, as well as oil, fuel, and coolant temperature sensors. These components ensure reliable performance and prevent costly failures. Monitoring sensor health is essential for optimal ISL engine function.

Switches and Related Components for Cummins ISL Engines

Switches are key to controlling oil, fuel, and coolant systems. Our range includes oil pressure, fuel pressure, and coolant temperature switches. Reliable switches protect the engine by activating warnings or controls during abnormal conditions. Regular testing and replacement prevent unexpected engine shutdowns.

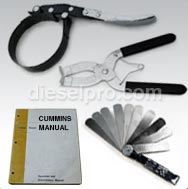

Manuals & Tools and Related Resources for Cummins ISL Engines

Proper tools and manuals are essential for efficient repairs and maintenance. We offer comprehensive service manuals and specialty tools such as feeler gauges, pullers, and filter wrenches. These resources help technicians and operators maintain their ISL engines with confidence. Investing in the right tools reduces repair times and prevents errors.

Starter & Alternator and Related Components for Cummins ISL Engines

Reliable starting and power generation are crucial for daily operations. Our starters and alternators, along with mounting hardware and electrical connectors, keep the ISL engine powered and running. High-quality components reduce downtime and support consistent performance. Preventative replacement of worn units helps avoid costly delays.

Hose, Clamp and Related Components for Cummins ISL Engines

Secure hoses and clamps maintain proper fluid transfer throughout the engine. We offer durable coolant and oil hoses, reinforced clamps, and high-quality fittings. Maintaining proper connections prevents leaks and ensures system reliability. Regular inspections help identify weak points before they cause breakdowns.

Fuel Filters and Related Components for Cummins ISL Engines

Fuel filters protect injectors and pumps from contaminants. We provide primary and secondary filters, water separators, and filter housings designed for ISL engines. High-efficiency filtration ensures clean fuel delivery, supporting performance and longevity. Regular filter changes are vital for system protection.

Oil Filters and Related Components for Cummins ISL Engines

Oil filters maintain clean oil flow, removing particulates and contaminants. Our range includes high-capacity filters, housings, and seals. These components are critical for engine protection and performance. Regular oil filter maintenance extends engine life and reduces wear.

FAQs for Cummins ISL Engine

-

What are the key features of the Cummins ISL engine?

The Cummins ISL engine offers a robust design, with an inline six-cylinder configuration, high torque output, fuel-efficient operation, and compliance with modern emissions standards. It’s widely used in trucks, buses, refuse vehicles, and construction equipment. -

Is the Cummins ISL engine designed for marine applications?

No, the ISL is not marine-rated. It’s specifically engineered for on-highway and industrial applications such as transportation, construction, and waste management. -

What are common maintenance intervals for the ISL engine?

Key maintenance includes oil and filter changes every 15,000 to 25,000 miles, coolant system checks, fuel filter replacements, and regular valve adjustments as per Cummins guidelines. -

How can I identify the correct parts for my Cummins ISL engine?

Locate your engine’s serial number and consult with Diesel Pro Power’s detailed catalog to match the correct parts for your engine’s specific configuration. -

What are common issues with Cummins ISL engines?

Common concerns include EGR system issues, turbocharger wear, fuel injector problems, and sensor failures. Regular maintenance and using quality replacement parts help prevent these issues.

FAQs for Cummins ISL Overhaul Kits

-

What is included in a Cummins ISL overhaul kit?

A complete overhaul kit typically includes pistons, rings, bearings, gaskets, and seals, designed to restore the engine to like-new performance. -

When should I consider an overhaul for my Cummins ISL engine?

Overhauls are recommended when the engine shows signs of wear such as power loss, excessive oil consumption, or high blow-by levels. -

Do overhaul kits come with installation instructions?

Many kits include detailed instructions, but it’s recommended to consult a service manual or professional mechanic for best results. -

Are Cummins ISL overhaul kits available for different configurations?

Yes, kits are tailored to specific ISL configurations and may vary based on year, emissions level, and application. -

How long does it take to install an ISL overhaul kit?

Installation times vary depending on experience and tools, but professional shops may complete a full overhaul in a few days.

FAQs for Cummins ISL Cylinder Head

-

What are common signs of a failing cylinder head in a Cummins ISL?

Symptoms include coolant leaks, white smoke, compression loss, and overheating, which often indicate a crack or gasket failure. -

Can I purchase a cylinder head with or without valves for my ISL?

Yes, Diesel Pro Power offers both options, allowing you to choose based on your rebuild needs. -

What is the torque specification for ISL cylinder head bolts?

Torque specifications vary, but generally, Cummins recommends a multi-step tightening sequence using precise torque values. -

How do I identify the correct cylinder head for my ISL engine?

Check your engine serial number and consult with Diesel Pro Power’s catalog to ensure correct fitment. -

Should I replace valve springs and seals when installing a new cylinder head?

Yes, it’s often recommended to replace springs, seals, and inserts to ensure optimal valve operation and compression.

FAQs for Cummins ISL Oil Pump

-

What does the oil pump do in a Cummins ISL engine?

The oil pump circulates oil to lubricate moving parts and cool engine components, critical for longevity. -

What are signs of a failing oil pump in my ISL engine?

Low oil pressure, unusual noises, and overheating are common signs of oil pump issues. -

Can I replace just the oil pump or should I replace related components too?

While replacing the oil pump is key, it’s advisable to check for wear in related parts like the oil cooler, seals, and gaskets. -

How do I choose the right oil pump for my ISL engine?

Use the engine serial number and consult Diesel Pro Power’s catalog to ensure you select the correct pump. -

Do I need special tools to install a new oil pump in my ISL engine?

Standard mechanical tools and a service manual are usually sufficient, but always consult manufacturer instructions.

FAQs for Cummins ISL Water Pump

-

Why is the water pump important in the Cummins ISL engine?

The water pump circulates coolant to prevent engine overheating and maintain optimal operating temperatures. -

What are signs of a bad water pump in my ISL engine?

Coolant leaks, overheating, and whining noises often indicate a failing water pump. -

Should I replace the thermostat when replacing the water pump?

Yes, replacing the thermostat along with the water pump ensures efficient coolant regulation and avoids future issues. -

Are Cummins ISL water pumps interchangeable across all models?

Not always—water pumps can vary by engine configuration, so it’s essential to verify compatibility with your engine serial number. -

How often should the water pump be inspected or replaced?

Regular inspection is recommended every 100,000 miles, or sooner if symptoms of wear appear.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588