Cummins ISL Parts - Rebuild Kit Section

Loading...

Loading... Cummins ISL Engine Parts Catalog – Rebuild Kit Section

Overview of the Cummins ISL Engine

The Cummins ISL is a mid-range, heavy-duty diesel engine that has become a popular choice for both on-highway and industrial applications. Known for its durability, fuel efficiency, and performance across a range of environments, the ISL engine platform powers everything from buses and trucks to construction equipment and stationary industrial systems.

Originally introduced as part of Cummins' L Series engine family, the ISL offers multiple horsepower ratings and has evolved over the years to include variants such as the ISL9 and its QSL industrial counterpart. Common features include:

-

Electronic control via Cummins' ECM

-

High-pressure fuel injection

-

A robust cast iron block with integrated oil cooling

-

Variable geometry turbocharging in later models

Given its widespread use, rebuild and maintenance solutions for the ISL are in high demand. Diesel Pro Power supports engine owners, operators, and repair professionals with access to high-quality rebuild kits and supporting components designed to meet or exceed OEM standards.

ISL Rebuild Kits – Complete Solutions for Engine Overhaul

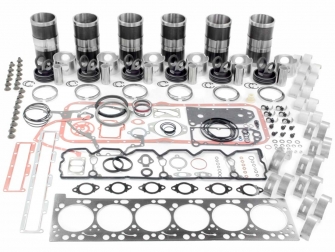

Cummins ISL Rebuild Kit with 2-Piece Pistons

This rebuild kit includes components required to fully restore the performance and compression integrity of the Cummins ISL and QSL engines. It is designed for engines with CPLs such as 1096, 2701, and 2736, among others.

What’s Included in a Standard ISL Rebuild Kit

Each rebuild kit typically contains:

-

Pistons (2-piece articulated pistons)

-

Piston rings

-

Cylinder liners

-

Connecting rod bearings

-

Main bearings

-

Thrust washers

-

Upper and lower gasket sets

The inclusion of 2-piece pistons is critical to performance. These are articulated pistons, which means the steel crown and aluminum skirt are separate components that allow better heat resistance under high combustion pressures—a necessary feature for heavy-duty use in the ISL.

Compression Ratio Explanation

While the ISL rebuild kit above does not list a specific compression ratio, many ISL engines feature ratios between 16.6:1 and 17.0:1 depending on CPL and application. Compression ratio is a measure of how much the engine compresses air before ignition. A higher compression ratio generally leads to better thermal efficiency, more torque, and improved fuel economy—but it also increases combustion temperatures, requiring robust piston design.

Always match the correct compression ratio to your CPL to avoid engine performance issues or failure.

Piston Cooling Nozzles for Cummins ISL and Related Engines

Role of Piston Cooling Nozzles

Piston cooling nozzles are essential for maintaining optimal piston temperature, especially in engines with articulated pistons. These nozzles spray oil upward onto the underside of the piston crown, helping dissipate the intense heat generated during combustion.

Options Available

-

1.22" Nozzle Length: These nozzles are compatible with Cummins ISL, QSL, L10, and ISC engines that use articulated pistons. Each engine requires six nozzles.

-

1.73" Nozzle Length: A longer variant for engines that require greater oil flow coverage beneath the piston.

Failure to replace worn or clogged nozzles during a rebuild can result in piston overheating, scoring, or eventual failure.

Front and Rear Crankshaft Seal Kits for Cummins ISL

Importance of Crankshaft Seals

Crankshaft seals are located at the front and rear ends of the engine block. Their primary function is to prevent oil leaks where the crankshaft exits the engine casing.

There are multiple variations depending on application:

-

Suitable for ISL, QSL, ISC, and 6CTA8.3 engines

-

Includes both the main seal and the wear sleeve

-

Used in non-automotive or industrial applications

-

Available in standard and double-lip configurations

-

Options for wet clutch housing applications

-

Double-lip seals offer added sealing performance and durability

Replacing front and rear crankshaft seals during a rebuild ensures long-term leak prevention and protects the engine from contamination and oil loss.

Filtration Components for Cummins ISL Engine

Engine Oil Filters

An oil filter ensures the lubricating oil is free from contaminants that could cause premature wear or failure. The filters listed for ISL engines are spin-on types, offering easy installation during regular maintenance or overhaul. Proper oil filtration:

-

Reduces engine wear

-

Extends oil life

-

Maintains consistent oil pressure

Common specifications include a diameter of around 4.65 inches and height up to 11.69 inches. The thread size varies but is typically compatible with ISL/QSL platforms.

Fuel Filters and Water Separators

Efficient fuel filtration is crucial for high-pressure common-rail fuel systems used in modern ISL engines.

Available Configurations:

-

Standard Fuel Filters: Capture debris and contaminants before they reach injectors.

-

Fuel Filters with Water Separator: Remove both particulate matter and water from diesel fuel. Water can damage injectors and degrade fuel quality, making this component especially important for marine or high-humidity environments.

Water separators with diameters of 3.66" to 4.65" are available, each supporting different thread sizes for ISL-compatible housing units.

Rocker Cover Gaskets and Gasket Sets

During a top-end overhaul or a complete rebuild, replacing gaskets is essential. The rocker cover gasket seals the valve cover, preventing oil from leaking out of the top of the engine and keeping contaminants from entering.

Key Notes:

-

Gaskets are application-specific. Ensure compatibility with your ISL variant.

-

Complete upper and lower gasket kits are included in rebuild kits, but individual gaskets can be purchased separately as needed.

Specialty Tools for ISL Maintenance and Rebuild

Feeler Gauges

Feeler gauges are used during valve adjustment procedures. For ISL engines, a standard range of .002" to .025" is sufficient to set the valve lash correctly.

Regular valve lash adjustment ensures proper combustion, reduced emissions, and optimal engine performance.

Piston Ring Assembly Tool

Installing piston rings without damaging them requires a proper ring compressor or piston ring tool. These tools help guide the rings into the cylinder smoothly, preventing breakage or misalignment.

Oil and Fuel Filter Removal Wrenches

These specialty wrenches accommodate a range of filter sizes. The two most relevant for ISL applications include:

Using the correct wrench prevents overtightening or damaging filters during installation or removal.

Temperature Switches and Radiator Cleaners

Temperature switches control fan or engine cutoff functions and are vital for safe operation of ISL-powered systems. A standard temperature switch for ISL closes at 205°F, protecting the engine from overheating.

Radiator cleaner supports long-term coolant system health. It removes scale, corrosion, and sludge, which can otherwise lead to blockages or inefficient cooling—especially critical in heavy-duty or high-load environments.

Mechanical and Electrical Gauges for ISL Monitoring

Maintaining visibility into engine vitals is critical for industrial and on-road ISL applications.

Gauge Options Include:

-

Standard Mechanical Gauges: Oil pressure, coolant temperature, and fuel levels

-

Gauges with Alarm Functions: Provide visual or audible alerts during critical conditions

-

12V and 24V Electrical Gauges: Compatible with various vehicle and equipment setups

Installing reliable instrumentation ensures real-time feedback and helps operators respond before minor issues turn into costly failures.

Final Thoughts on Rebuilding a Cummins ISL Engine

Rebuilding your Cummins ISL engine using a high-quality kit restores its original power, compression, and fuel economy while extending its service life for thousands of additional hours. Whether you're operating in a bus fleet, generator system, or construction site, a properly rebuilt ISL can provide dependable service when paired with OEM-grade components and best-practice maintenance.

Key Reminders:

-

Always verify your engine’s CPL number before ordering a rebuild kit.

-

Replace supporting components such as piston nozzles, seals, and filters during the rebuild.

-

Use correct torque specs and installation tools to avoid engine damage.

-

Consider professional calibration after rebuild to maximize performance.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588