Cummins ISM Parts - Rebuild Kit Section

Loading...

Loading... Cummins ISM Parts Catalog – Rebuild Kit Section

Overview of the Cummins ISM Engine

The Cummins ISM is a high-performance, mid-displacement diesel engine widely used in industrial, on-highway, and vocational applications. With a displacement of 10.8 liters and a reputation for durability and torque, this inline 6-cylinder engine evolved from earlier models like the M11 and L10, offering increased efficiency and lower emissions through electronic fuel control systems.

Designed with a robust cast-iron block, wet liners, and advanced piston designs, the ISM is commonly found in buses, heavy-duty trucks, construction equipment, and stationary power units. When these engines reach high operating hours, a full rebuild can restore their original performance, improve fuel economy, and extend service life by thousands of hours.

Rebuild Kits for Cummins ISM Engines

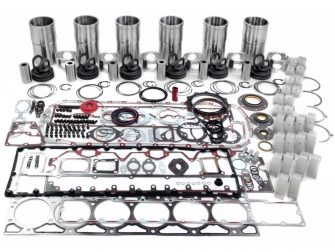

Rebuild Kit for ISM, M11, and L10 with 1-Piece Pistons

This rebuild kit is tailored for Cummins ISM engines using one-piece pistons, which are forged from high-strength aluminum alloy and optimized for thermal conductivity and weight. The pistons are typically paired with steel cylinder liners, standard or oversized rings, and matched bearing sets.

This kit is compatible with dozens of Cummins CPL numbers found in industrial and on-highway ISM engines. Applications include transit vehicles, cement mixers, agricultural machines, and standby power units.

Kit Contents:

-

One-piece aluminum pistons with rings (standard or oversize available)

-

Cylinder liners with seals

-

Main bearings and connecting rod bearings

-

Thrust washers

-

Upper and lower gasket sets including oil pan, valve cover, and head gaskets

Compression Ratios

ISM engines with one-piece pistons often use compression ratios between 16.3:1 and 17.0:1. These ratios support high cylinder pressures while maintaining balanced combustion temperatures, which is key for longevity and fuel efficiency in heavy-duty applications.

Rebuild Kit for ISM and M11 with 2-Piece Pistons

This kit is built for Cummins ISM and M11 engines featuring 2-piece articulated pistons, which consist of a forged steel crown and aluminum skirt. These pistons are used in applications requiring higher thermal resistance and mechanical strength—such as mining, marine, or oilfield equipment.

These engines operate under sustained load and temperature extremes, which makes precise component compatibility critical for a successful rebuild.

Kit Contents:

-

2-piece articulated pistons with pins and retainers

-

Piston rings

-

Wet cylinder liners

-

Main and rod bearings

-

Complete gasket kit

-

Thrust washers

Compression Ratios

Articulated piston designs often support slightly higher compression ratios—typically 17.0:1 to 17.5:1—which improves torque and cold-weather starting. This is especially important in stationary or off-highway units where engines may be required to start and operate under heavy load immediately.

Key Components for a Complete ISM Rebuild

A complete rebuild includes more than just pistons and gaskets. Supporting components that regulate oil, fuel, cooling, and airflow should be replaced to ensure the engine operates at peak efficiency.

Piston Cooling Nozzles

Cummins ISM engines utilize piston cooling nozzles to spray oil directly onto the piston underside, helping regulate temperature during operation. These nozzles are essential for preventing crown damage, skirt scoring, and piston seizure—especially in 2-piece piston configurations.

-

One nozzle is required per cylinder (six per engine)

-

Compatible with ISM, M11, and QSM engine families

-

Replace during every major rebuild to prevent future overheating issues

Piston Nozzle Mounting Bolts

These specialized bolts hold the piston cooling nozzles in place under high vibration and heat. They are designed for single-use only and should be replaced during a rebuild to ensure secure mounting and proper oil flow alignment.

-

Six bolts per engine required

-

Torque to factory specification for consistent oil spray pattern

Rear Crankshaft Seal Kit

The rear crankshaft seal is a critical component to prevent oil leakage from the rear main bearing housing. Modern ISM engines use a double-lip seal paired with a wear sleeve to ensure a long-lasting seal even under fluctuating crankcase pressures.

-

Designed for later model engines

-

Includes seal and installation sleeve

-

Prevents rear main oil leaks and clutch/flywheel contamination

Oil Filters

A clean, high-capacity oil filter is crucial to protect new pistons, bearings, and camshaft lobes from contamination during engine break-in. Cummins ISM engines use a large-diameter spin-on filter designed for high oil flow and thermal resistance.

-

Ensure thread compatibility and bypass valve function

-

Replace with every oil change during and after break-in

Fuel Filters

ISM fuel systems rely on clean fuel delivery for injector performance and emissions compliance. Modern fuel filters capture particles down to microns in size and prevent injector scoring or premature nozzle failure.

Diesel Pro Power offers multiple fuel filter styles:

-

Compact filters for tight engine compartments

-

Larger filters with higher holding capacity

-

Water separator filters to eliminate moisture before it enters the injection system

Fuel Filter & Water Separator

Water separators help protect the fuel injection system from corrosion, especially in marine or humid environments. A combined fuel filter and water separator should be used where fuel quality is uncertain or in older fuel tank systems prone to condensation.

-

Designed with high water-retention capacity

-

Drain plug or bowl included in most configurations

-

Recommended for construction equipment and standby generators

Recommended Tools for ISM Engine Overhaul

Feeler Gauge for Valve Lash Adjustment

Accurate valve lash settings are essential after head installation or camshaft servicing. The ISM engine requires precise intake and exhaust lash to maintain cylinder pressure and airflow balance.

-

Ranges from 0.002" to 0.025"

-

Use with engine at top dead center (TDC)

-

Calibrate all six cylinders during reassembly

Fuel Filter Removal Wrench

A filter removal wrench saves time and prevents damage when removing spin-on fuel filters. Diesel Pro Power offers a wrench compatible with ISM fuel filters ranging from 3-7/16" to 3-3/4" in diameter.

-

Ergonomic handle

-

Non-slip gripping surface

-

Fits most Cummins and Detroit Diesel filters

Oil Filter Removal Wrench

Oil filter access on the ISM can be tight, especially in equipment with limited service bays. A filter wrench designed for diameters between 4-21/32" and 5-5/32" ensures easy removal without crushing the canister.

Piston Ring Installation Tool

This tool allows for uniform compression of piston rings during installation into the cylinder bore. Prevents breakage and ensures rings seat properly for maximum compression.

-

Suitable for standard and oversized rings

-

Works with one-piece and articulated pistons

-

Improves safety and speed of rebuilds

Cooling System Maintenance

Radiator Cleaner

During a full overhaul, cleaning the cooling system is essential to prevent overheating and coolant restriction. Radiator cleaners are designed to remove scale, oil residue, and rust buildup from internal coolant passages.

-

Safe for aluminum, cast iron, and brass

-

Compatible with Cummins coolant systems

-

Recommended flush before adding fresh coolant

Temperature Switch

This switch activates cooling fans and temperature alarms. Replacing it during rebuild prevents engine overheating caused by faulty sensor data. The standard switch closes at approximately 205°F and fits directly into most ISM cooling circuits.

-

Threaded for easy installation

-

Suitable for most Cummins, Caterpillar, and Detroit Diesel engines

-

Ensure compatibility with the control panel or alarm system

Gauges for Engine Monitoring

Monitoring a rebuilt engine is vital, especially during the break-in period. Diesel Pro Power offers analog and digital gauges to ensure temperature, oil pressure, and voltage stay within safe limits.

Mechanical Gauges

-

Oil pressure, coolant temperature, and boost pressure

-

No power supply needed

-

Reliable and rugged for industrial use

Electrical Gauges (12V & 24V)

-

Easy to integrate into existing panels

-

Compatible with most OEM sending units

-

Optional alarms for real-time alerts

Why Choose Diesel Pro Power for Your ISM Overhaul?

At Diesel Pro Power, we specialize in supplying CPL-specific overhaul kits and components for Cummins ISM engines. Our kits are matched for precision fit and performance, eliminating guesswork and reducing rebuild time.

What Sets Us Apart:

-

Kits tailored to CPL numbers for guaranteed compatibility

-

Components sourced from OEM-equivalent manufacturers

-

Decades of diesel engine expertise

-

Over 40,000 satisfied customers worldwide

-

Fast international shipping and expert support

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588