Cummins KTA 19 Engine Parts - Crankshaft Section

Loading...

Loading... Crankshaft Components for Cummins KTA19 Engines

The crankshaft is the mechanical heart of the Cummins KTA19 engine, delivering rotational torque from the combustion process to the flywheel and driveline. Whether installed in marine propulsion systems, power generation units, or heavy industrial platforms, the KTA19 crankshaft must withstand immense stresses over thousands of operating hours. Diesel Pro Power provides a complete catalog of crankshaft-related components—new crankshafts, precision bearing sets, seal kits, and gasket assemblies—to keep your engine running at peak performance.

Each component is engineered to exact Cummins specifications and built for durability in high-load, continuous-duty environments.

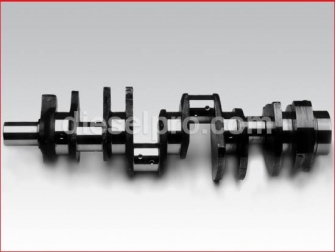

New Crankshaft for Cummins KTA19 and QSK19 Engines

Fully Forged Crankshaft – Factory-Grade Construction

Our new crankshaft for Cummins KTA19, KT19, and QSK19 engines is built from forged steel, heat-treated for strength, and precision-ground to meet OEM tolerances. This crankshaft is internally balanced and features a six-throw inline design, making it ideal for large displacement six-cylinder engines used in marine and industrial applications.

-

Applications: KTA19, KT19, and QSK19 platforms

-

Material: Forged and hardened steel

-

Design: Inline-6 layout with full counterweighting

-

Balance: Internally balanced for smoother operation and longer bearing life

-

Common Use Cases: Marine vessels, industrial pumps, power generation systems, and oilfield service equipment

Each crankshaft is thoroughly inspected for straightness, journal sizing, and oil passage cleanliness before shipping, ensuring it's ready for installation without modification.

Crankshaft Bearing Shell Sets

Diesel Pro Power offers crankshaft bearing sets in Standard and three oversize options to match your rebuild requirements. All sets include a complete set of upper and lower shells for every main journal.

Standard Size Crankshaft Bearings

Standard-size bearings are designed for use with crankshafts that have not been reground and are still within original manufacturing tolerances.

-

Fitment: Crankshafts with factory-original journal diameters

-

Material: Tri-metal construction (steel backing, copper/lead intermediate layer, soft overlay)

-

Use Case: Full engine overhauls where crankshaft shows no significant journal wear

0.010" Oversize Crankshaft Bearings

If the crankshaft journals have been ground down by 0.010 inches, these bearings are required to restore the correct oil clearance and maintain lubrication integrity.

-

Size Difference: Increased internal thickness for reground crankshafts

-

Use Case: Engines with minor crankshaft journal scoring or taper

-

Machining Requirement: Journals must be precision-ground to 0.010" undersize before installation

0.020" Oversize Crankshaft Bearings

These bearings accommodate crankshafts that have been reground by 0.020 inches, often needed when previous wear is more severe but the crankshaft is still structurally sound.

-

Use Case: Moderate wear correction during rebuilds

-

Bearing Surface: Same tri-metal layering for high load tolerance

-

Common Fitment: Heavily used marine engines, generator sets with high hour counts

0.030" Oversize Crankshaft Bearings

For engines where the crankshaft has been re-machined by 0.030 inches, these oversized bearings offer maximum compensatory thickness to restore OEM-level oil clearance.

-

Application: Deep journal wear, scoring, or pitting

-

Usage Note: Only install after professional crankshaft inspection and journal grinding

-

Ideal For: Engines where the crankshaft is being reused but requires maximum undersize machining

All crankshaft bearings carried by Diesel Pro Power are rigorously tested to withstand high bearing loads, thermal expansion, and continuous operation typical of the KTA19’s service environments.

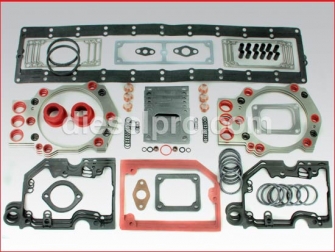

Front and Rear Crankshaft Seal Kits

Front Crankshaft Seal Kits

Diesel Pro Power offers two types of front crankshaft seal kits, depending on your KTA19 engine's timing cover configuration. Both options include:

-

Primary oil seal

-

Wear sleeve or spacer

-

Dust protection seal (on certain kits)

Proper front seal function prevents oil leakage from the timing gear housing and protects components like pulleys and belts from oil contamination.

Rear Crankshaft Seal Kits (Wet and Dry Housing Variants)

Depending on your engine’s housing configuration, Diesel Pro Power offers rear seal kits for:

-

Wet Housing Engines: Seal kit includes oil-rated radial seal and wear sleeve

-

Dry Housing Engines: Kit includes high-temperature seal, typically with added dust exclusion design

These seals are crucial during crankshaft replacement, transmission interface service, or major bottom-end rebuilds. Always verify your engine’s housing type before selecting a seal kit to ensure proper fitment.

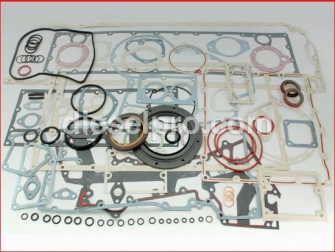

Gasket Sets Related to Crankshaft Installation

Lower Gasket Sets

Diesel Pro Power supplies lower gasket sets tailored for KT19 and KTA19 variants:

-

KT19 Gasket Set: Designed for turbocharged engines without an aftercooler

-

KTTA19 Gasket Set: For aftercooled turbocharged engines

Each set includes:

-

Oil pan gasket

-

Front and rear cover gaskets

-

Crankshaft seal interface gaskets

-

Housing and main cap sealing components

These sets are highly recommended when replacing the crankshaft or performing a complete bottom-end overhaul.

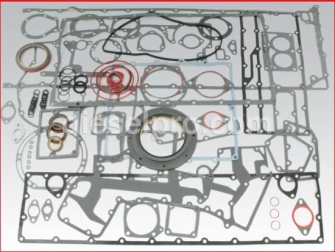

Upper Gasket Sets (Commonly Paired with Crankshaft Jobs)

Upper gasket sets are often replaced alongside the crankshaft during full engine rebuilds. Diesel Pro Power offers upper gasket sets for:

Each kit includes cylinder head gaskets, push rod seals, valve cover gaskets, and more—ensuring top-end sealing complements the refreshed bottom-end.

Diagnosing Crankshaft Wear in Cummins KTA19 Engines

Common indicators of crankshaft damage or bearing wear include:

-

Low engine oil pressure despite full oil levels

-

Knocking or rumbling sounds at idle or under load

-

Metal particles in the oil pan or oil filter

-

Frequent rear or front crankshaft seal leaks

-

Out-of-balance vibration during engine acceleration

-

Premature bearing wear or discoloration

Any of these symptoms should trigger a teardown and inspection of the crankshaft and associated components.

Causes of Crankshaft Failure

-

Poor lubrication or oil starvation

-

Improper torque of main bearing caps

-

Excessive engine load or detonation

-

Worn or unbalanced flywheel assembly

-

Incorrect bearing installation

-

Skipped seal replacement during prior service

Early intervention and replacement of affected crankshaft components can prevent catastrophic failure and extend the life of your Cummins KTA19 engine.

Crankshaft Installation Tips

When installing a crankshaft in a KTA19 or QSK19 engine:

-

Verify all journal sizes using a micrometer

-

Match bearings to crankshaft sizing: Standard, 0.010", 0.020", or 0.030"

-

Clean all oil passages in the crankshaft and block thoroughly

-

Use assembly lubricant on journals and bearings before turning the crank

-

Torque main bearing caps using a calibrated torque wrench, in sequence

-

Check end play using a dial indicator

-

Install new front and rear seal kits

-

Use lower gasket set to reseal the crankcase properly

Fitment Guidelines

When ordering crankshaft parts for your Cummins KTA19, consider:

-

CPL Number: Confirms internal specs and compatibility

-

Cooling Configuration: Aftercooled vs. non-aftercooled determines gasket set selection

-

Journal Condition: Use proper bearing size (standard or oversize)

-

Housing Type: Determines correct rear seal kit (wet vs. dry)

-

Application Environment: Marine, stationary, or mobile equipment use may dictate service intervals

Still unsure? Diesel Pro Power’s technical team can assist with component identification based on your serial number or CPL.

Trusted by 40,000+ Diesel Professionals Worldwide

Diesel Pro Power is the go-to supplier for Cummins KTA19 crankshaft components. Our extensive inventory supports:

-

Full engine overhauls

-

Emergency repairs

-

Preventive maintenance

-

Reconditioning of high-hour marine diesels

-

Power generation rebuilds

With same-day shipping, professional support, and OEM-level quality, our parts are trusted across industries where downtime is not an option.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588