Cummins KTA 50 Engine Parts - Cylinder Head Section

Loading...

Loading... -

Cylinder Head for Cummins KTA19, KTA38, KTA50 QSK19

3081064NV

NEW - Standard head with valves and springs. (valves have washers under springs)

Price: $ 1,441.33 -

Cylinder Head for Cummins KTA19, KTA38, KTA50, QSK19

3811985NV

NEW - Premium head with valves and springs. (valves have rotocoils under springs)

Price: $ 1,876.45 -

-

Cylinder Head Bolt Washer for Cummins KTA & QSK Series Engines

205059

6 per head - new cylinder head bolt washer for Cummins KTA & QSK; ensures proper torque per head.Price: $ 2.79 -

-

-

-

-

-

Cummins Exhaust Valve Kit for K19, K38 & K50 engines

3803529

Stellite Material - Code “S” or “E”Price: $ 43.15 -

Valve Guide For Cummins QSK19, K19, K38, K50 Engines

3202210

For intake and exhaust valvesPrice: $ 7.89 -

-

-

-

-

-

-

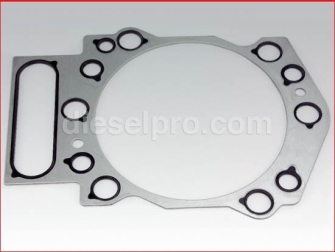

Head Gasket for Cummins KTA19, KTA38, KTA50 and QSK19

3634664

6 needed to service entire engine.Price: $ 67.12 -

-

-

-

-

-

-

-

-

-

-

Temperature switch for Detroit Diesel, Cummins, Caterpillar engines

5146080

Closes at 205 degrees Fahrenheit.Thread size is 1/2 NPTPrice: $ 97.19

Cummins KTA50 Engine Parts – Cylinder Head Section

The Cummins KTA50 engine is one of the most powerful and reliable heavy-duty engines in Cummins’ high-horsepower product line. Designed for use in industrial, marine, mining, and power generation applications, the KTA50 delivers unmatched performance, durability, and fuel efficiency. Maintaining peak performance requires high-quality cylinder head components—ranging from complete head assemblies to valve train elements and gasket systems. Below is a comprehensive catalog of cylinder head components available for the Cummins KTA50 engine, with updated details including the fact that this engine uses 16 individual cylinder heads and requires 16 head gaskets for a complete top-end rebuild.

Complete Cylinder Head Assemblies for KTA50

Standard Cylinder Head Assembly with Valves and Springs

This OEM-style cylinder head is preassembled with intake and exhaust valves as well as valve springs. The springs utilize traditional washers underneath and are compatible with Cummins’ original design. Built to precise tolerances, this head provides a reliable, cost-effective option for KTA50 engine users. Suitable for marine propulsion, industrial gensets, and oilfield applications where simplicity, reliability, and ease of maintenance are key.

Premium Cylinder Head Assembly with Rotocoils

Designed for extended durability, the premium cylinder head includes rotocoils beneath the valve springs. These help rotate the valves during operation, reducing hot spots and valve seat wear. This version is ideal for high-load, continuous-duty engines—particularly in power generation and marine settings—where top-end longevity is essential.

Note: The KTA50 V16 engine requires 16 individual cylinder heads—one per cylinder—for a complete top-end service.

Cylinder Head Gaskets and Gasket Sets

When rebuilding or servicing the KTA50’s cylinder head system, a complete upper gasket set is essential. This set typically includes:

-

16 cylinder head gaskets (one per cylinder)

-

Intake and exhaust manifold gaskets

-

Valve cover gaskets

-

Turbocharger gaskets

-

Injector seals

-

Rocker lever cover gaskets

-

Cam follower cover gaskets

Using a full OEM-grade gasket set ensures proper sealing of combustion chambers, coolant passages, and oil channels—minimizing the risk of leaks under extreme temperature and pressure.

Each cylinder on the KTA50 requires a dedicated head gasket—16 in total for the full engine. These gaskets are made from multi-layered steel or other heat-resistant materials designed to endure combustion chamber pressures and thermal cycling. Precision thickness ensures the correct compression ratio is maintained.

Always replace all 16 head gaskets during a full top-end rebuild to maintain balanced compression and prevent localized failures.

Rocker Lever Housing and Cover Gaskets

In addition to head gaskets, proper sealing of rocker lever housings and cam follower covers is critical. Gaskets for these areas are designed to:

-

Prevent oil leaks

-

Maintain internal pressure

-

Protect valve train components

Ensure these gaskets are replaced whenever rocker assemblies or cam housings are disturbed during servicing.

Valve Train Components

Intake and Exhaust Valve Kits

KTA50 intake and exhaust valves are available in both standard and high-performance configurations:

-

Standard valves offer a cost-effective solution for general-duty operation.

-

Stellite-coated valves improve heat and wear resistance.

-

Inconel valves provide the highest level of durability and are recommended for engines that run at or near maximum load for long durations.

Each kit typically includes:

-

Valve(s)

-

Valve seals

-

Keepers/locks

-

Retainers

Valve Guides and Seat Inserts

Valve guides maintain stem alignment, reducing side-loading and preventing premature wear. High-strength guides are available for both intake and exhaust valves.

Seat inserts (valve seats) are machined from hardened alloys and pressed into the head to serve as the valve's sealing surface. Choose seat materials that match your application—whether industrial, marine, or power generation.

Valve Spring Components

Valve Springs

Valve springs for the KTA50 must maintain consistent pressure through millions of cycles. Choose high-tensile, fatigue-resistant springs engineered for your engine’s RPM range and valve lift.

Valve Spring Retainers and Guides

Spring retainers hold the spring in place, while spring guides help keep the spring aligned during movement. In high-RPM environments, even minor misalignment can lead to accelerated wear or catastrophic failure.

Crosshead Brackets and Valve Rotators

Crosshead Valve Brackets

These brackets distribute force from the rocker arms evenly across dual valves per cylinder. KTA50 engines rely on robust, precision-machined crossheads to ensure accurate valve timing and prevent uneven wear.

Valve Rotators (Rotocoils)

Rotocoils improve valve longevity by rotating the valve slightly during actuation, which minimizes hot spots and promotes even seat wear. These are especially critical in constant-duty applications such as offshore generators and industrial compressors.

Push Rods and Cam Follower Assemblies

Valve and Injector Push Rods

The KTA50 uses separate push rods for intake/exhaust valves and fuel injectors. These rods must:

-

Resist bending under load

-

Remain perfectly straight

-

Be replaced if pitting or galling is present

Always check for oil channel blockages before reuse.

Cam Follower Rollers and Pins

Roller followers translate camshaft rotation into vertical movement to operate valves and injectors. Rollers reduce friction, while hardened pins hold the assembly in place. Replace worn followers or damaged pins during any cam service or rebuild.

Supporting Cylinder Head Components

Cam Follower and Rocker Cover Gaskets

Gaskets for these assemblies must resist high temperatures and contact with diesel engine oil. Always inspect and replace these gaskets during cylinder head removal or service intervals.

Hex Nuts and Rocker Arm Adjusters

Critical fasteners throughout the head and rocker assemblies must be properly torqued during installation. Over- or under-tightening can lead to valve timing issues, poor performance, or component damage.

Benefits of Using Premium Cylinder Head Components for Cummins KTA50

Choosing the correct top-end components for your KTA50 engine offers several advantages:

-

Maintain Proper Compression: Matching gasket thickness and valve geometry to OEM specs helps retain the correct compression ratio.

-

Withstand Harsh Conditions: Heat-treated valves and hardened seats resist high exhaust temps common in marine and power gen use.

-

Minimize Downtime: Durable parts reduce service frequency and ensure long maintenance intervals.

-

Improve Fuel Efficiency: Proper valve function and sealing improve combustion and lower fuel consumption.

-

Extend Engine Life: Prevents failure modes that can result in costly unplanned overhauls.

KTA50 Cylinder Head Maintenance Tips

-

Always replace all 16 cylinder head gaskets during a full rebuild.

-

Use a feeler gauge to verify and adjust valve lash at regular intervals.

-

Inspect valve guides, push rods, and crossheads for wear during each major service.

-

Replace rocker cover gaskets and cam follower cover gaskets after each removal.

-

Monitor coolant temperature to avoid overheating and head warpage.

-

Use rotocoil-style heads for applications with long runtime at full load.

Common Applications for KTA50 Engines

The Cummins KTA50 is a true workhorse and is commonly found in:

-

Marine propulsion: Tugboats, offshore supply vessels, ferries

-

Power generation: Emergency and base-load gensets

-

Mining equipment: Haul trucks, excavators, drills

-

Oil and gas: Well service pumps, compressors, mud pumps

-

Rail transport: Industrial locomotives and rail-mounted cranes

In every one of these environments, uptime is mission-critical. That’s why investing in quality cylinder head parts for your KTA50 isn’t just a matter of performance—it’s a matter of operational reliability.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588