Cummins M11 Parts - Rebuild Kit Section

Loading...

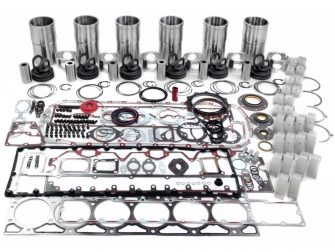

Loading... Cummins M11 Rebuild Kits – Complete CPL-Matched Overhaul Guide for Marine and Industrial Applications

The Cummins M11 engine is a workhorse in both marine and industrial sectors, trusted for its reliability, torque delivery, and versatility. Whether it's powering a dredging pump, pushing a workboat, or supporting a generator in a remote mining camp, the M11 provides the performance needed for demanding environments. However, over time—due to wear, operating conditions, or poor maintenance—engine internals begin to degrade, making a complete rebuild necessary to return the engine to peak performance.

This guide outlines the rebuild kits available for Cummins M11 engines, emphasizing CPL (Control Parts List) compatibility, component configurations like piston design, and additional parts that should be replaced during a rebuild to ensure longevity and proper function. Each kit and supporting component discussed below is intended to support marine and industrial M11 applications.

Engine Overview: Cummins M11 Platform

The Cummins M11 is a direct-injected, inline-six diesel engine developed as the successor to the older L10 model. It comes in a range of CPLs tailored to different end-use requirements—from marine propulsion systems to stationary power and industrial equipment.

Common Features:

-

Displacement: 10.8 liters

-

Bore x Stroke: 125 mm x 147 mm

-

Turbocharged with aftercooling

-

Available with one-piece or two-piece pistons

-

Fuel system: Mechanical and CELECT electronic fuel systems

-

Applications: Marine propulsion, generators, mining equipment, drilling rigs, pumps, and more

Marine vs. Industrial Variants:

-

Marine engines often run at constant RPM for long durations and benefit from materials optimized for saltwater and thermal management.

-

Industrial engines usually experience fluctuating load conditions, requiring greater resilience to high torque cycles and environmental contaminants like dust.

Compression ratios vary by CPL, typically ranging from 16.0:1 to 17.0:1. These ratios are integral to combustion performance. Engines with higher compression ratios tend to deliver better fuel efficiency and more torque but may experience more stress on internal components.

Overhaul Kit Breakdown by CPL & Piston Type

1. Cummins M11 Marine Overhaul Kit – CPL-Specific

This rebuild kit is engineered for M11 engines used in marine environments and includes two-piece articulated pistons, which are standard in high-performance marine applications.

CPL Compatibility: 2199, 2200, 2350, 2376, 2477, 2562, 2563, 2576, 2607, 2608, 2610, 2611, 2612, 2614, 2615

Included Components:

-

Two-piece pistons with steel crowns and aluminum skirts

-

Piston rings

-

Piston pins with retainers

-

Wet cylinder liners

-

Main and rod bearings

-

Upper and lower gasket sets

-

Front and rear oil seals

Compression Ratio: Generally 16.0:1 or 16.5:1, which provides smoother power delivery at sustained loads typical in marine propulsion.

Use Case: Ideal for engines powering tugboats, fishing trawlers, or offshore supply vessels. The articulated piston design reduces piston slap and resists high thermal cycling.

2. M11 / ISM / L10 Overhaul Kit – One-Piece Piston Configuration

This rebuild kit supports both industrial and marine engines using one-piece pistons. One-piece pistons are forged as a single unit, offering structural simplicity and improved heat dissipation under moderate loads.

CPL Compatibility: 1827 through 2918 (inclusive of dozens of variants)

Piston Type: One-piece aluminum pistons

Compression Ratio: Typically 16.5:1 to 17.0:1, depending on CPL

Use Case: Suited for equipment such as power generation units, drilling rigs, and other fluctuating load environments.

Notable Features:

-

Easier installation compared to two-piece piston kits

-

Optimized for industrial applications where thermal cycles vary

-

Often used in Tier-compliant rebuilds

3. M11 / ISM Overhaul Kit – Two-Piece Pistons

A heavy-duty rebuild solution with two-piece pistons for high-torque applications, supporting extended CPL ranges.

CPL Compatibility: 2725, 2727–2731, 2800, 3280–3281, 3330, and 8271 through 8572

Compression Ratio: Generally 16.0:1 or 16.5:1, depending on the CPL

Benefits:

-

Greater resistance to crown erosion and skirt collapse under extreme pressure

-

High thermal resistance for use in engines operating under long, steady load cycles

Applications: Marine propulsion, industrial gen-sets, oil and gas extraction platforms

Additional Parts to Replace During a Cummins M11 Overhaul

An overhaul isn’t just about replacing pistons and liners. Neglecting to replace supporting components can reduce rebuild effectiveness and lead to premature failures. Below are critical ancillary components and why they should be included in your rebuild strategy.

Piston Cooling Nozzles

Piston cooling nozzles (also called oil squirters) spray engine oil directly onto the underside of the pistons, reducing thermal stress and preventing overheating.

-

Quantity Needed: 6 per engine

-

When to Replace: Any time pistons are replaced, especially for engines with known thermal loading or high exhaust temperatures

-

Importance: Critical for preventing piston scuffing and ensuring optimal ring life and compression integrity

Crankshaft Seal Kits – Front and Rear

The front and rear main seal kits include sealing rings and sleeves. It's recommended to replace them during every overhaul.

-

Why Replace: Seals degrade over time due to pressure and temperature fluctuations. Old seals may cause oil leaks post-rebuild.

-

Marine Note: Engines with wet clutch housings require a specific double-lip rear seal.

Filtration System Components

Fresh filters ensure clean lubrication and fuel delivery from the first startup.

-

Spin-on filters with appropriate thread and size specifications

-

Use matched filters based on your CPL’s fuel system

-

Include both primary and secondary filters if applicable

Fuel Filter & Water Separators:

-

Crucial for marine and remote industrial setups where water contamination is a concern

Calibration and Maintenance Tools

Tools like a feeler gauge or piston ring assembly tool are essential for accurate reassembly. Improper installation can ruin a rebuild.

-

Required for adjusting valve lash to precise tolerances

-

Prevents ring breakage or scoring during installation

-

Aid in removing and replacing high-torque fuel filter housings

Cooling and Vibration Control

-

Recommended after every rebuild to remove residue, rust, and sludge from the cooling system

Vibration Isolators:

-

Four are typically used per engine and are crucial in marine mounts or generator bases

-

Control the cooling fan or alarm systems and should be tested or replaced during an overhaul

Rebuild Kit Selection Tips

Selecting the correct overhaul kit depends on accurately identifying your engine's CPL number. This number determines:

-

Compression ratio

-

Piston type (1-piece vs. 2-piece)

-

Liner compatibility

-

Rod and main bearing sizing

-

Gasket set match (upper and lower sets are CPL-specific)

Always verify your engine CPL before ordering a rebuild kit. Installing the wrong components can lead to poor combustion, piston damage, or catastrophic failure.

Compression Ratios and Performance

The compression ratio affects everything from combustion timing to emissions and fuel economy. Higher compression improves thermal efficiency but may stress pistons and bearings more severely. Matching the correct piston configuration and compression ratio to your engine CPL ensures:

-

Optimized fuel injection timing

-

Proper valve clearance

-

Balanced combustion temperatures

-

Avoidance of detonation and power loss

Why Choose Diesel Pro for Cummins M11 Rebuild Kits?

Diesel Pro Power offers CPL-matched rebuild kits engineered for real-world durability. With over 40,000 satisfied customers globally, our components are built for high-load applications like marine propulsion and industrial equipment. Every kit is assembled based on the correct compression ratio, piston design, and gasket profile to ensure a seamless fit and dependable performance.

Additional benefits include:

-

Expert support in identifying the correct CPL and overhaul solution

-

Stocked parts ready for fast shipping

-

Supportive components like filters, seals, and tools available from the same source

-

Multilingual service and international delivery

Final Thoughts on Cummins M11 Overhaul Kits

Rebuilding a Cummins M11 engine is a major investment that pays dividends in restored power, reliability, and operational lifespan. Choosing the right overhaul kit matched to your engine’s CPL—and replacing all critical supporting components—ensures the job is done right the first time. Whether you're maintaining a fleet of industrial engines or preparing a marine propulsion system for its next decade of service, Diesel Pro Power is your partner for sourcing high-quality rebuild kits and parts with confidence.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588