Cummins N14 Engine Parts - Crankshaft Section

Loading...

Loading... Cummins N14 Engine Parts – Crankshaft & Related Components

The Cummins N14 is a proven workhorse in both on-highway and industrial applications, known for its durability, high torque output, and service life that often exceeds a million miles with proper care. At the heart of this performance lies the crankshaft assembly and its related components. Responsible for converting the linear motion of the pistons into rotational power, the crankshaft and its supporting parts—bearings, seals, dampers, and sleeves—must be maintained to exacting standards.

Diesel Pro Power provides high-quality new and replacement crankshaft components for the Cummins N14, trusted by 40,000+ satisfied customers worldwide. Below you’ll find an in-depth guide to crankshaft components and related parts to keep your N14 running at peak performance.

Crankshaft for Cummins N14 Engines

The crankshaft is the backbone of the N14’s bottom end. Precision forged and machined, it must withstand immense stresses generated by combustion and rotational inertia. A properly balanced crankshaft ensures smooth operation, reduces vibration, and contributes to extended engine life.

-

New Crankshafts – Manufactured to OEM specifications, new crankshafts offer exact tolerances for journal size, oiling passages, and balance. This ensures a perfect fit with N14 bearings and pistons.

-

Applications – Suitable for all variants of the N14 engine, whether used in heavy-duty trucks, power generation, or industrial equipment.

-

Performance Considerations – A worn crankshaft can result in loss of oil pressure, bearing damage, and increased vibration. Replacement should be considered whenever scoring, cracks, or excessive wear are detected.

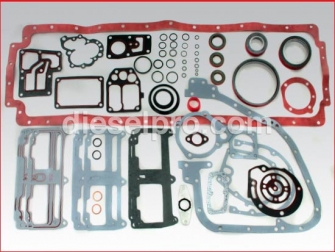

Gasket Sets Supporting the Crankshaft

While not directly part of the rotating assembly, gasket sets play a crucial role in sealing the N14’s crankshaft system and ensuring proper lubrication.

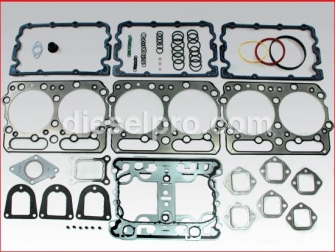

Upper Gasket Set

Designed for the top end of the engine, this set includes seals and gaskets for cylinder heads, valve covers, and intake systems. A tight seal ensures oil and coolant do not leak into the crankcase, protecting the crankshaft from contamination.

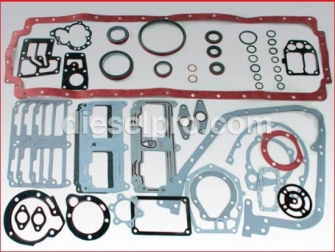

Lower Gasket Set

The lower gasket set is essential for sealing around the crankcase, oil pan, and block.

-

Pre-1993 Engines – Specific lower gasket sets designed for early builds of the N14.

-

1994 and Later Engines – Updated gasket materials and designs for later N14 engines to match Cummins engineering revisions.

A complete gasket set replacement is often performed alongside a crankshaft rebuild to prevent oil leaks and ensure long-term reliability.

Crankshaft Bearings (Shell Sets)

The crankshaft shell bearings provide a smooth, replaceable surface for the crankshaft journals to ride on. They maintain precise oil clearance and protect the crankshaft from direct wear.

-

Standard Shell Sets – Designed for crankshafts within original factory dimensions. These are the default choice when no machining has been performed.

-

Oversize Bearings – Available in .010" and .020" increments, these bearings are used when crankshaft journals have been machined undersize. This ensures a perfect fit and restores proper oil clearance.

-

Complete Sets – Include both upper and lower halves for every crank journal, ensuring even wear distribution across the entire rotating assembly.

Vibration Damper for Cummins N14

High-output engines like the N14 generate substantial torsional vibration during operation. A vibration damper absorbs these harmonic oscillations, preventing crankshaft fatigue and improving longevity.

-

Specifications – The N14 damper measures 13.54” in diameter, engineered for precise harmonic balancing.

-

Applications – Fits both the Cummins 855 and N14 series, making it a reliable solution for fleets running multiple engine families.

-

Maintenance Insight – Dampers should be inspected during major overhauls. A failed damper can lead to crankshaft cracks and catastrophic engine damage.

Crankshaft Seal Kits

Preventing oil leakage around the crankshaft is vital to keeping an N14 engine reliable. Seal kits include the sealing lip and a wear sleeve to ensure proper installation and durability.

Front Crankshaft Seal Kit

Located behind the vibration damper, the front crankshaft seal prevents oil leaks from the timing cover area. It is commonly replaced during damper service or when signs of oil seepage are present.

Rear Crankshaft Seal Kits

Two variations are available depending on clutch configuration:

-

Dry Clutch Engines – A rear seal kit designed to keep oil out of the flywheel housing.

-

Wet Clutch Engines – A specialized version with enhanced sealing properties for engines using a wet clutch system.

These kits are engineered to OEM specifications, ensuring long-lasting protection against leaks and contamination.

Wear Sleeves for Rear Crankshaft Seals

Over time, crankshaft sealing surfaces can develop grooves from constant seal contact. A wear sleeve provides a new sealing surface without requiring crankshaft replacement.

-

Applications – Specifically designed for rear crankshaft seals on the N14.

-

Benefits – Restores proper sealing surface, prevents premature seal failure, and saves on costly crankshaft replacement.

Oil Seals for Fan Hub

In addition to crankshaft-specific seals, the N14 uses oil seals in related rotating assemblies such as the fan hub. These seals prevent oil leaks in the accessory drive system, maintaining proper lubrication and preventing engine bay contamination.

Maintenance & Installation Tips for N14 Crankshaft Components

-

Proper Torqueing – Always use Cummins-recommended torque specs for crankshaft bolts and bearing caps to avoid distortion.

-

Lubrication During Assembly – Apply assembly lube or clean engine oil to bearings, seals, and journals before installation.

-

Balance & Alignment – If replacing the crankshaft, ensure proper alignment and balance to prevent vibration and premature wear.

-

Regular Inspections – Monitor oil pressure and listen for knocking noises; these can indicate bearing wear or crankshaft misalignment.

-

Seal Installation Tools – Use the correct Cummins service tools to install seals and sleeves without distortion.

Why Choose Diesel Pro Power for Cummins N14 Crankshaft Components?

-

Extensive Inventory – Full coverage of crankshaft assemblies, bearings, seals, dampers, and supporting gaskets.

-

Trusted by 40,000+ Customers – Diesel Pro Power is a global supplier with decades of experience supporting Cummins-powered fleets.

-

Worldwide Shipping – Fast delivery to minimize downtime.

-

Expert Support – Our team specializes in Cummins engines, offering technical guidance for selection and installation.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588