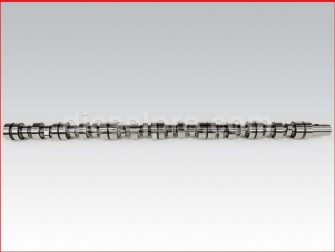

Cummins NT855 Engine Parts - Camshaft Section

Loading...

Loading... Camshaft & Related Components for Cummins NT855 Engines

The camshaft is the heartbeat of any four-stroke diesel engine, and in the Cummins NT855, it plays a critical role in timing the opening and closing of the intake and exhaust valves with precision. Whether you're rebuilding an NT855 for industrial use or performing preventive maintenance on a marine powerplant, ensuring that your camshaft and related components are in optimal condition is essential for peak performance and long engine life.

At Diesel Pro Power, we stock a full range of Cummins NT855 camshafts and supporting hardware — trusted by over 40,000 satisfied customers worldwide.

Camshaft Options for Cummins NT855 Engines

The NT855 engine family includes both Small Cam and Big Cam variants. These camshafts are not interchangeable, and each is designed to accommodate specific lifter diameters and valve timing profiles.

Small Cam, Flangeless Camshaft for Cummins 855NH and 855NT Engines

The Small Cam design is a hallmark of earlier 855 engines. It features smaller diameter tappets (cam followers) and is compatible with vintage 855NH and NT855 configurations. The flangeless design simplifies installation, particularly in applications where space is limited.

This type of camshaft is ideal for operators restoring older marine engines or vintage industrial gensets that require OEM-spec profiles and high-precision machining. Diesel Pro Power’s inventory of small cam components ensures exact-fit compatibility and dependable performance for long service life.

Big Cam, Flangeless Camshaft for Cummins NT855 Engines

The Big Cam design was introduced by Cummins as an upgrade over the Small Cam variant, primarily to improve airflow and combustion efficiency. This version includes a larger camshaft journal diameter and larger tappets to allow for more aggressive cam profiles.

Big Cam NT855 engines dominate marine and heavy industrial sectors due to their enhanced power output, improved fuel efficiency, and better emissions performance. If your NT855 is a Big Cam model, replacing the camshaft with an exact-match flangeless Big Cam unit is crucial for maintaining proper valve and injector timing.

Supporting Components for Camshaft Installation & Operation

A camshaft rebuild or replacement involves more than just swapping the cam. Several additional parts play a key role in ensuring a leak-free, well-aligned, and properly lubricated camshaft system.

Accessory Drive Cover Oil Seal

Located at the front of the engine, the accessory drive cover oil seal prevents oil leaks where the accessory drive interfaces with the front gear train. It's essential to replace this seal whenever the camshaft or accessory drive components are serviced to maintain oil pressure and cleanliness in the timing gear area.

Camshaft Bushing Set for Big Cam Engines

Camshaft bushings provide the rotational support the camshaft needs to operate with minimal friction. For Cummins NT855 Big Cam engines, a full bushing set is necessary when performing a top-end rebuild or full engine overhaul. Replacing worn bushings is a cost-effective way to prevent premature wear of the camshaft journals and reduce engine vibration.

These bushings are precision-machined for proper oil clearance and alignment, allowing for consistent lubrication of the camshaft during operation.

Fan Hub Oil Seal for NH855, NT855, and N14 Engines

The fan hub oil seal helps prevent oil leakage where the fan drive connects to the front of the engine block. While not directly tied to camshaft operation, this seal is often replaced during camshaft-related service because of its location behind the front cover.

Failing to replace a worn fan hub seal can result in engine bay contamination, loss of oil pressure, and damage to rotating components.

Push Rods for Cummins NT855 Valve and Injector Rockers

Push rods are responsible for transmitting camshaft movement to the valve and injector rockers. They must be perfectly straight and matched to the camshaft profile and engine configuration. Diesel Pro Power offers push rods for both Big Cam and Small Cam NT855 engines.

Push Rods for Valve Rockers (855NH and 855NT)

For Big Cam NT855 engines, each cylinder requires two push rods for the intake and exhaust valve rockers. In a six-cylinder configuration, that totals 12 valve push rods per engine. These components are engineered to resist flexing under high stress and deliver reliable motion transfer for consistent valve actuation.

Push Rods for Injector Rockers – Big Cam Configuration

In Big Cam variants, the camshaft also drives fuel injectors via dedicated injector push rods. Cummins NT855 Big Cam engines require six injector push rods — one per cylinder. These rods are slightly different in length and profile compared to valve push rods, and should always be matched to Big Cam-specific cam profiles.

Push Rods for Injector Rockers – Small Cam Configuration

Small Cam NT855 engines also utilize six push rods for injector activation, but the rod specifications differ due to the altered geometry of the Small Cam layout. Using the wrong type of injector push rod can lead to poor injection timing, misfires, or damage to the rocker arms and camshaft lobes.

Why Camshaft Health Matters in Cummins NT855 Engines

The NT855’s performance and longevity depend on precise valve timing, synchronized injection, and smooth camshaft rotation. Over time, camshaft lobes can wear down, become pitted, or develop flat spots, especially in high-hour engines. Even minor imperfections can drastically impact performance.

Signs of a worn camshaft include:

-

Irregular valve timing

-

Low compression

-

Decreased fuel efficiency

-

Misfiring or hard starts

-

Excessive valve lash

-

Ticking or knocking noises from the valve cover

If you're experiencing any of these symptoms, a camshaft inspection — and possible replacement — should be prioritized.

Common Applications for Cummins NT855 Camshaft Components

Cummins NT855 engines are used in a wide range of applications, including:

-

Commercial marine vessels (tugboats, fishing boats, workboats)

-

Industrial generators

-

Offshore drilling platforms

-

Large-scale agricultural tractors and harvesters

-

Heavy-duty mining and construction equipment

-

Water pump and irrigation systems

-

Locomotive auxiliary power units

Whether your NT855 is powering a remote diesel genset in the Amazon or a commercial fishing boat in the Gulf, maintaining camshaft integrity is mission-critical. That's why marine operators, maintenance yards, and fleet managers trust Diesel Pro Power for fast shipping and accurate parts fulfillment.

Tips for Installing a New Camshaft in an NT855 Engine

Replacing or upgrading a camshaft in an NT855 engine is a precision task. Follow these best practices for a successful install:

-

Check bearing clearances: Always verify camshaft bushing internal diameters against Cummins specifications.

-

Use new oil seals: Replace all front cover, fan hub, and accessory seals to prevent leaks.

-

Pre-lube all contact points: Apply engine assembly lubricant to camshaft journals, lobes, and bushings during installation.

-

Set valve lash and injector timing correctly: Incorrect lash or timing can destroy a new camshaft within hours.

-

Inspect push rods and rockers: Replace any bent, worn, or pitted push rods to ensure even load transfer.

-

Align the timing gear properly: A single tooth misalignment can cause valve interference and engine failure.

Why Choose Diesel Pro Power for NT855 Camshaft Parts?

With over 40,000 satisfied customers and decades of experience in Cummins diesel engine support, Diesel Pro Power is your trusted source for:

-

OEM-quality replacement camshafts

-

Precision-machined camshaft bushing sets

-

Engine-specific push rods for valve and injector rockers

-

Oil seals and gasket components for complete camshaft service

We offer same-day shipping, competitive pricing, and expert customer support to get your Cummins NT855 engine back in service quickly — no matter where in the world you operate.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588