Cummins QSB 4.5 Parts - Oil Section

Loading...

Loading... Cummins QSB 4.5L Oil Pump & Lubrication System Components

The Cummins QSB 4.5L diesel engine is widely recognized for its durability and smooth operation in marine, industrial, and heavy-duty applications. One of the most critical systems ensuring that durability is the lubrication system, with the oil pump serving as the heart of this network. At Diesel Pro Power, we provide a complete selection of oil pumps, gaskets, oil coolers, filters, and related components designed to keep your QSB 4.5L engine running at peak performance. With over 40,000 satisfied customers worldwide, our parts are trusted by professional operators and enthusiasts alike.

Importance of the Oil Pump in the QSB 4.5L Engine

The oil pump plays a vital role in the lubrication system by drawing oil from the sump and distributing it under pressure to key engine components. This ensures friction reduction, cooling, and protection against premature wear. On the QSB 4.5L engine, the oil pump design varies based on the gear train configuration — either rear gear train or front gear train— and each requires precise fitment to ensure optimal performance.

Oil Pump Options for the Cummins QSB 4.5L

Rear Gear Train Oil Pump

-

Design & Compatibility: Built for QSB 4.5L engines with a rear-mounted gear train, these pumps feature helical gear teeth (23/24 tooth configuration) for smoother operation and reduced gear noise.

-

Performance Benefits: The helical design minimizes vibration, delivers consistent oil pressure, and helps extend the life of engine bearings and other moving parts.

-

Common Applications: Marine propulsion engines, generator sets, and stationary power units where rear gear trains are common.

Front Gear Train Oil Pump

-

Design & Compatibility: Designed for engines with a front-mounted gear train, these pumps use straight-cut gear teeth (22/24 tooth configuration) for efficient, direct power transfer.

-

Performance Benefits: While slightly noisier than helical gears, straight-cut designs offer higher mechanical efficiency and durability under heavy load conditions.

-

Common Applications: Industrial equipment and applications where a front gear train layout is used for easier maintenance access.

Oil Pick-Up Tube Gaskets

An oil pump is only as effective as the seal integrity in the lubrication system. The gasket for the oil pick-up tube ensures no air enters the system, preventing cavitation and ensuring uninterrupted oil flow.

-

Material & Durability: Built from high-quality gasket materials designed to resist oil breakdown, heat, and vibration.

-

Installation Tip: Always replace the pick-up tube gasket when servicing or replacing the oil pump to ensure proper sealing.

Oil Coolers for the QSB 4.5L

Oil coolers maintain the optimal operating temperature of engine oil, preventing viscosity breakdown and ensuring reliable lubrication under demanding conditions.

-

Standard 7-Plate Oil Cooler: Efficiently dissipates heat in medium-load marine and industrial operations.

-

Rear Gear Train Oil Cooler: Designed specifically for QSB 4.5L engines with a rear gear configuration, ensuring maximum cooling efficiency and minimal pressure drop.

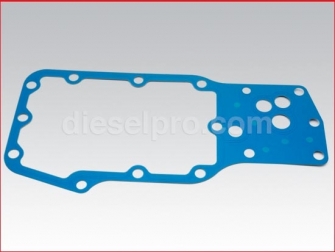

Oil Cooler Gaskets & Seals

To prevent oil leaks and cross-contamination between oil and coolant, properly fitted gaskets are essential. Our selection includes:

-

Oil Cooler Cover Gaskets: Provide a tight seal between the oil cooler body and its protective cover.

-

Core Gaskets: Seal the oil cooler core within the housing, preventing leaks and ensuring consistent cooling performance.

-

Metal Core Gaskets: Offer increased durability for high-temperature and high-pressure conditions.

Oil Filtration Components

Clean oil is the lifeblood of the QSB 4.5L. Our oil filtration solutions include:

-

Spin-On Oil Filters: Designed for quick changes, with a high dirt-holding capacity and precise filtration efficiency to protect engine internals.

-

Filter Dimensions: Standard QSB 4.5L filters have a compact profile for easy installation while maintaining optimal flow rates.

-

Oil Filter Removal Tools: Adjustable wrenches that fit a range of filter diameters, making servicing faster and safer.

Oil Pressure Monitoring & Protection

Maintaining correct oil pressure is crucial to engine longevity. We carry a range of oil pressure switches to suit different operational requirements:

-

5 PSI Make/Break: Ideal for early-warning low-pressure alarms.

-

10 PSI, 20 PSI, and 27 PSI Switches: For varied monitoring thresholds based on engine load, application, and OEM specifications.

-

Durability: Designed to withstand vibration, heat, and oil exposure common in marine and industrial environments.

Mechanical & Electric Oil Pressure Gauges

-

Mechanical Gauges: Provide a direct reading using pressurized oil — preferred in certain heavy-duty and marine applications for their reliability.

-

Electrical Gauges (12V & 24V): Compatible with modern dash panels and offer remote monitoring capability.

-

Gauges with Alarm: Include built-in warning systems to alert operators immediately of oil pressure drops.

Maintenance Recommendations for the QSB 4.5L Oil System

-

Regular Oil Changes: Maintain oil quality and viscosity by following Cummins service intervals.

-

Inspect Seals & Gaskets: Prevent oil loss and maintain system pressure.

-

Monitor Oil Pressure: Use a reliable gauge or switch to catch pressure drops early.

-

Replace Filters on Schedule: Clogged filters restrict flow and can cause premature wear.

-

Inspect Oil Coolers: Clean regularly to prevent heat buildup that can damage oil quality.

Why Choose Diesel Pro Power for Your QSB 4.5L Oil System Parts

-

Global Shipping: We deliver parts to customers worldwide, supporting marine operators, industrial users, and fleet managers.

-

Expert Support: Our team understands Cummins engines inside and out, providing accurate part selection assistance.

-

Quality Assurance: Every component meets or exceeds OEM performance standards.

-

Trusted by Thousands: Over 40,000 satisfied customers rely on our products for critical operations.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588