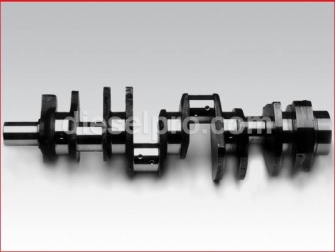

Cummins QSB 6.7 Parts - Crankshaft Section

Loading...

Loading... Crankshafts & Related Components for Cummins QSB 6.7L

Overview of the Cummins QSB 6.7L Crankshaft

The crankshaft is one of the most vital components in the Cummins QSB 6.7L diesel engine, serving as the mechanical backbone that transforms linear piston motion into rotational energy. In marine and industrial applications, the crankshaft must endure constant high-load operation, varying RPM demands, and the corrosive environments often encountered at sea or in heavy-duty equipment. The QSB 6.7L crankshaft is engineered from high-strength forged steel, precision-machined to exact tolerances to ensure optimal balance, minimal vibration, and maximum durability over thousands of operating hours.

In this engine, the crankshaft is a seven-main-bearing design, which provides stability and reduces torsional stress. Its journals are hardened for long service life, and oil passageways are precision-drilled to maintain consistent lubrication, even during extended periods of high-load operation. Whether in a commercial fishing vessel, passenger ferry, or stationary industrial generator, the crankshaft’s reliability directly determines the smoothness and longevity of the entire powerplant.

Applications of the QSB 6.7L Crankshaft

The Cummins QSB 6.7L is widely used in:

-

Marine propulsion – powering yachts, workboats, ferries, and fishing vessels.

-

Marine auxiliary engines – driving onboard generators and hydraulic systems.

-

Industrial equipment – such as mining machinery, agricultural pumps, and drilling rigs.

-

Commercial standby generators – where the crankshaft must provide consistent rotational speed under sudden load changes.

In each of these roles, the crankshaft is subjected to different torque curves, thermal loads, and vibration patterns, all of which make proper maintenance and correct part replacement critical.

Common Causes of Crankshaft Wear in the QSB 6.7L

Even with robust design, the crankshaft can experience wear or damage over time due to:

-

Oil starvation or low oil pressure – leading to bearing scoring and journal damage.

-

Improper engine alignment in marine shaft-driven systems – causing torsional stress and bending.

-

Contaminated lubrication – from dirt, debris, or coolant intrusion, accelerating bearing and journal wear.

-

Overloading or overspeeding – particularly in marine applications where propeller loading may exceed design limits.

Replacement Considerations

When replacing a crankshaft in a QSB 6.7L engine, several factors must be considered to ensure long-term reliability:

-

OEM vs. Aftermarket Quality – Diesel Pro Power provides crankshafts that meet or exceed Cummins factory specifications for metallurgy, hardness, and balance.

-

Journal Size Matching – Crankshafts come in standard and undersized journal configurations to accommodate bearing replacement and machining history.

-

Torsional Damper Compatibility – The damper must be in good condition to prevent crankshaft twist or fracture.

-

Balancing Requirements – A properly balanced crankshaft reduces bearing wear and improves overall engine smoothness.

-

Bearing Set Replacement – Always replace main and rod bearings when installing a new crankshaft to prevent premature wear.

Related Components Available for the QSB 6.7L

When servicing or replacing a crankshaft, it’s recommended to address other components in the rotating assembly:

-

Main Bearings – Available in standard and undersize options for precise fitment.

-

Rod Bearings – To ensure smooth operation and prevent connecting rod scoring.

-

Thrust Washers – To control axial movement and prevent crank walk.

-

Crankshaft Seals – Both front and rear seals to prevent oil leakage.

-

Torsional Vibration Damper – Helps absorb harmonics and protect the crankshaft from fatigue.

-

Flywheel & Ring Gear Assemblies – Matched to the crankshaft for optimal engine balance.

-

Crankshaft Position Sensor – Ensures accurate engine timing and injection control.

Importance of Proper Installation

A crankshaft is not a simple drop-in component; its installation requires precision:

-

Inspection – Block saddles must be checked for alignment, straightness, and cleanliness.

-

Lubrication – All bearing surfaces should be pre-lubed before assembly.

-

Torque & Sequence – Main bearing caps must be tightened to specification in the correct sequence.

-

End Play Check – Proper axial movement must be verified using a dial indicator.

-

Pre-Lube Oil System – Before initial start-up, ensure the lubrication system is primed.

Incorrect installation can result in catastrophic damage, even to a brand-new crankshaft.

Maintenance Practices to Extend Crankshaft Life

-

Maintain Clean Oil – Regular oil and filter changes are essential.

-

Monitor Oil Pressure – Catch lubrication issues before they cause crankshaft damage.

-

Inspect Vibration Damper – Replace as needed to avoid harmonic-induced failure.

-

Balance Propeller Loads – In marine use, avoid over-pitching the propeller.

-

Avoid Excessive Idling – Low-speed operation can lead to uneven wear patterns.

Why Choose Diesel Pro Power for QSB 6.7L Crankshafts

With over 40,000 satisfied customers worldwide, Diesel Pro Power has earned a reputation for delivering high-quality marine and industrial diesel engine parts with fast, reliable service. Our QSB 6.7L crankshafts and related components are selected for their durability, exact fitment, and compliance with Cummins performance standards. We stock ready-to-ship parts, reducing downtime for vessel operators and industrial users.

Our team understands the specific needs of QSB 6.7L engines in high-demand environments and can provide expert guidance on crankshaft replacement, balancing, and associated parts selection. Every crankshaft ships inspected, protected for corrosion resistance, and packaged for safe transit worldwide.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588