Cummins QSB 6.7 Parts - Fuel Pump Section

Loading...

Loading... -

-

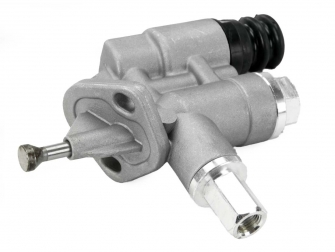

Cummins Fuel Transfer Pump

3936319

Pump Style Mechanical Piston, Used with non-rotary pumpsPrice: $ 101.38 -

-

-

-

-

Cummins Fuel Filter & Water Separator

3286503

3.02" diameter, 5.62" height, thread: M16 x 1.5" - 6H INTPrice: $ 44.78 -

-

-

-

1000 Racor Replacement fuel and water separator filter unit

1000

Filter element 2020 includedPrice: $ 449.65 -

-

-

-

-

-

-

Zinc for Cummins Marine Engine Fuel and Oil Coolers

3957921

Brass plug NPT 3/8”, zinc length 1”Price: $ 19.89 -

-

Fuel & Oil Pressure Switch - 10 PSI Make/Break

23520024

10 PSI make/break with 1/8 nptPrice: $ 99.79 -

Fuel & Oil Pressure Switch - 20 PSI Make/Break

23520025

20 PSI make, break with 1/8 nptPrice: $ 96.44 -

Fuel & Oil Pressure Switch - 27 PSI Make/Break

23511819

27 PSI make/break with 1/8 nptPrice: $ 72.10 -

Cummins QSB 6.7L Fuel Pump Parts Catalog

The Cummins QSB 6.7L engine is renowned for its reliability, power, and efficiency in marine, industrial, and off-highway applications. A critical element in maintaining that performance is ensuring your fuel system is functioning at its best. The fuel pump and related components are responsible for delivering clean, pressurized fuel to the injectors, ensuring optimal combustion and engine longevity.

This catalog provides a detailed look at all available fuel pump and fuel system parts for the Cummins QSB 6.7L, along with compatible components used across related Cummins platforms like the 4B, 4BT, 6B, 6BT, and 6BTA.

Fuel Transfer Pumps for Cummins QSB 6.7L

Mechanical Lever-Style Fuel Transfer Pump

The mechanical lever-style fuel transfer pump is a dependable option for QSB 6.7L owners who require consistent fuel delivery under various load conditions. This pump is particularly suited for engines operating in environments where electrical components may be exposed to moisture or vibration, as its mechanical design offers rugged reliability.

Key Features:

-

Compatible with QSB 6.7L and other mid-range Cummins platforms

-

Ideal for marine and industrial environments

-

Provides steady fuel delivery at all engine speeds

-

Robust construction for long-term durability

Mechanical Piston-Style Fuel Transfer Pump (For Non-Rotary Pumps)

For applications requiring non-rotary fuel delivery systems, the mechanical piston-style transfer pump is a proven choice. It offers precise fuel metering and is commonly used in industrial Cummins configurations where mechanical control is preferred over electronic regulation.

Advantages:

-

Works seamlessly with non-rotary fuel systems

-

Delivers reliable fuel volume under varying load demands

-

Long service life with proper fuel filtration

Fuel Pump Gaskets & Seals

Even the best fuel pumps require reliable sealing to prevent leaks and maintain system pressure. Cummins provides high-quality gaskets specifically designed for QSB 6.7 fuel pump applications.

Fuel Transfer Pump Gasket

A precision-cut fuel transfer pump gasket is essential for sealing the pump housing to the mounting flange. Two gaskets are typically required per pump to ensure complete sealing and vibration resistance.

Fuel Injection Pump Gasket

The fuel injection pump gasket ensures no fuel leaks between the injection pump and the engine block. Designed to handle high injection pressures, this gasket maintains its integrity even under prolonged heavy-load conditions.

Fuel System Electrical Components

12V Fuel Shutoff Solenoid

The fuel shutoff solenoid is a critical component in the Cummins QSB 6.7 fuel system, controlling fuel flow to stop the engine when required. Operating on a 12V system, it is built to withstand the vibrations and environmental challenges of marine and industrial settings.

Benefits:

-

Fast, reliable shutoff response

-

Durable coil and plunger assembly

-

Suitable for both start-stop and emergency shutdown functions

Fuel Filters & Water Separators

Clean fuel is the lifeblood of the QSB 6.7L. Contaminants like dirt, rust, and water can severely impact performance and cause expensive damage.

Standard Fuel Filter

The Cummins standard spin-on fuel filter is engineered to capture fine particulates while maintaining optimal fuel flow. It features a durable housing, corrosion-resistant baseplate, and precisely manufactured filter media.

Fuel Filter & Water Separator Combo

A fuel filter with an integrated water separator is an excellent choice for marine environments or any application where water contamination is a concern. It effectively removes water before it reaches the fuel injection system, preventing corrosion and injector damage.

Fuel Filter Service Tools

Fuel Filter Removal Wrench

Designed to fit multiple filter sizes, the fuel filter removal wrench ensures easy removal of even the most stubborn filters. The adjustable design accommodates both Cummins and Detroit Diesel fuel filters in common marine and industrial sizes.

Racor® Fuel Water Separator Systems & Elements

Racor’s fuel water separator systems are industry leaders in protecting diesel engines from water and particulate contamination. They are widely used in both Detroit Diesel and Cummins marine applications.

Available Units:

-

Racor 500 series fuel/water separators with replaceable 2010 elements

-

Racor 900 series fuel/water separators with 2040 elements

-

Racor 1000 series fuel/water separators with 2020 elements

Filter Element Options:

-

Brown Top (2 Micron) – Maximum filtration for ultra-clean fuel delivery

-

Red Top (30 Micron) – Higher flow rates for bulk fuel separation

Marine-Specific Fuel System Protection

Zinc Anodes for Fuel and Oil Coolers

In marine applications, fuel coolers are susceptible to galvanic corrosion. The zinc anode plug for Cummins QSB 6.7L fuel and oil coolers prevents costly damage by acting as a sacrificial metal, protecting the cooler’s internal surfaces.

Fuel & Oil Pressure Switches

Fuel and oil pressure switches play a critical role in monitoring engine health. For the QSB 6.7L, these switches can trigger alarms or safety shutdowns when pressures fall outside safe operating ranges.

Available PSI Settings:

-

5 PSI Make/Break

-

10 PSI Make/Break

-

20 PSI Make/Break

-

27 PSI Make/Break

Common Uses:

-

Fuel pump protection

-

Engine low oil pressure alerts

-

Automated shutdown systems for marine safety

Gauges for Monitoring Fuel System Performance

Monitoring your fuel system ensures optimal performance and early detection of issues. Available gauges include:

-

Mechanical Gauges – Simple, reliable, and vibration-resistant

-

Electrical Gauges (12V & 24V) – Easy to read with backlighting for night operation

-

Gauges with Alarm Functions – Provide both visual and audible alerts for critical fuel system conditions

Maintenance Tips for Cummins QSB 6.7 Fuel Systems

-

Replace Filters Regularly – Follow Cummins maintenance intervals or replace sooner in dusty or marine environments.

-

Inspect Fuel Lines & Gaskets – Look for leaks, cracks, and signs of wear.

-

Drain Water Separators Frequently – Especially in humid or marine conditions.

-

Test Fuel Pressure Switches – Ensure accurate readings to avoid false alarms or missed warnings.

-

Monitor for Symptoms of Pump Wear – Such as hard starting, loss of power, or increased fuel consumption.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588