Cummins QSB 6.7 Parts - Oil Section

Loading...

Loading... -

Cummins Oil Pump

4939587

For engines with a front gear train.

Pinions have 23/24 Helix Teeth.For engines with CPL#s 591, 599, 714, 721, 742, 831, 1279, 1288 ,1519, 1522, 1523, 1524, 1551, 1816, 1889, 1914, 1948, 1961, 1962, 1975, 2014, 2063, 2071, 2122, 2205, 2208, 2242, 2243, 2292, 2347, 2372, 2373, 2446, 2447, 2486, 2530, 2686, 2891, 2893, 8208, 8217, 8236, 8266, 8267, 8304, 8305, 8306, 8444

Price: $ 104.45 -

Cummins Oil Pump

4939588

For engines with a rear gear train.

Pinions have 22/24 Straight Teeth.For Engines With CPL#s 426, 427, 656, 1388, 1860, 2605, 2676, 2715, 3070, 3071, 3072, 3094, 3095, 3277, 3335, 3336, 3632, 3858, 3861, 3870, 3934, 4606, 4608, 4577, 4699, 4804, 8464, 8466, 8610, 8611, 8732

Price: $ 110.98 -

Cummins Oil Pump

4897481

For engines with a front gear train.

Pinions have 22/24 Straight Teeth.For engines with CPL#s 0742, 8206

Price: $ 104.45 -

-

-

-

-

-

-

Cummins Oil Filter

3908616

Spin-on type. 3.66" outside diameter, 5.35" height, thread size: 1-16 UNPrice: $ 25.74 -

Cummins Oil Filter

3937743

Spin-on type, 3.66" outside diameter, 6.95" height, thread size: 1-16 UNPrice: $ 32.80 -

Oil Filter Removal Wrench for Detroit Diesel, Caterpillar & Cummins

2321

4-21/32" to 5-5/32"Price: $ 63.29 -

-

-

-

Zinc for Cummins Marine Engine Fuel and Oil Coolers

3957921

Brass plug NPT 3/8”, zinc length 1”Price: $ 20.77 -

-

Fuel & Oil Pressure Switch - 10 PSI Make/Break

23520024

10 PSI make/break with 1/8 nptPrice: $ 99.79 -

Fuel & Oil Pressure Switch - 20 PSI Make/Break

23520025

20 PSI make, break with 1/8 nptPrice: $ 96.44 -

Fuel & Oil Pressure Switch - 27 PSI Make/Break

23511819

27 PSI make/break with 1/8 nptPrice: $ 81.10 -

Cummins QSB 6.7 Oil Pump & Lubrication System Components

The Cummins QSB 6.7 engine’s lubrication system is engineered to deliver consistent oil flow under varying loads, temperatures, and operational conditions. This section provides a complete catalog of oil pumps, oil cooling components, gaskets, filters, and related accessories designed for the QSB 6.7 platform, ensuring maximum reliability and long service life.

Oil Pumps for Cummins QSB 6.7

The oil pump is the heart of the lubrication system, responsible for circulating oil to all moving parts of the engine. QSB 6.7 oil pumps are precision-machined to maintain optimal pressure and flow rates, even in high-load industrial and marine applications.

Front Gear Train Oil Pump – Helix Tooth Pinions

Designed for QSB 6.7 engines equipped with a front gear train, this oil pump features 23/24 helix tooth pinions. The helical design ensures smoother engagement, reduced noise, and efficient power transfer to the pump. Ideal for engines operating in continuous-duty environments where smooth operation is critical.

Rear Gear Train Oil Pump – Straight Tooth Pinions

For engines with a rear gear train, this oil pump utilizes 22/24 straight tooth pinions for robust engagement and durability. The straight-tooth design offers simplicity and excellent torque handling, making it suitable for heavy-duty workboats, construction equipment, and industrial power units.

Front Gear Train Oil Pump – Straight Tooth Pinions

Another option for front gear train configurations, this pump features 22/24 straight tooth pinions for dependable performance. It is commonly used in specific QSB 6.7 configurations where straight-tooth engagement is preferred for maintenance or compatibility reasons.

Oil System Gaskets & Seals

Maintaining a leak-free lubrication system is critical for protecting engine components and maintaining oil pressure. High-quality gaskets and seals are essential for both assembly and long-term operation.

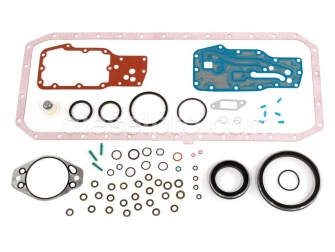

Lower Gasket Set for QSB 6.7

A complete lower gasket set designed for the QSB 6.7 platform, including seals and gaskets for the oil pan, timing cover, and related components. Manufactured to OEM standards to ensure proper sealing and longevity.

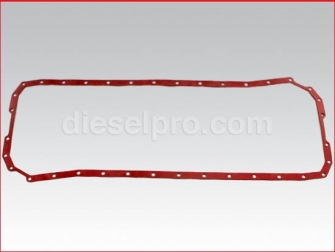

Oil Pan Gasket

A direct-fit replacement gasket for the oil pan, providing a reliable seal between the pan and engine block to prevent leaks under high vibration and temperature fluctuations.

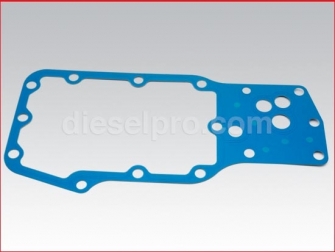

Oil Pick-Up Tube Gasket

Essential for sealing the oil pick-up tube to the oil pump, preventing air from entering the lubrication system. Compatible with 4B, 6B, ISB, and QSB engine families.

Oil Cooling Components

An efficient oil cooling system keeps lubricant at the correct temperature, preventing thermal breakdown and maintaining its protective properties.

Standard Oil Cooler – 7 Plate

A durable oil cooler designed with seven plates for efficient heat exchange. Suitable for QSB 6.7 marine and industrial engines, helping maintain safe operating temperatures in demanding conditions.

Rear Gear Train Oil Cooler

Designed specifically for QSB 6.7 engines with a rear gear train, ensuring optimal oil temperature control and system reliability.

Oil Cooler Cover Gaskets

Specially cut to fit the QSB 6.7 oil cooler housing, these gaskets maintain a secure seal to prevent coolant or oil leaks.

Oil Cooler Core Gaskets – Standard and Metal Options

Available in both composite and metal designs, these gaskets seal the core of the oil cooler, preventing cross-contamination between oil and coolant.

Oil Filtration Components

Filtration is vital for removing contaminants from the oil, protecting bearings, camshafts, and other precision components.

Spin-On Oil Filters – Standard Height

Features a compact design with a robust canister for marine and industrial environments. Built to withstand high oil pressure and capture fine contaminants.

Spin-On Oil Filters – Extended Height

Provides increased filtration capacity and longer service intervals. Ideal for engines operating in heavy-duty or continuous-use environments.

Oil Filter Removal Wrench

Adjustable wrench designed to fit oil filters ranging from 4-21/32 inches to 5-5/32 inches in diameter. Suitable for Detroit Diesel, Caterpillar, and Cummins engines.

Marine Oil System Accessories

Zinc Anode for Oil and Fuel Coolers

Protects marine oil and fuel coolers from internal corrosion. Constructed with a brass plug and NPT 3/8” threads, with a zinc element measuring 1” in length.

Oil Pressure Monitoring Components

Maintaining correct oil pressure is essential for QSB 6.7 engine longevity. Pressure switches and gauges provide critical feedback to operators.

Fuel & Oil Pressure Switch – 5 PSI Make/Break

Activates or deactivates circuits at 5 PSI, suitable for alarms and safety shutdown systems.

Fuel & Oil Pressure Switch – 10 PSI Make/Break

Triggers at 10 PSI for use in specific operational requirements where higher oil pressure thresholds are needed.

Fuel & Oil Pressure Switch – 20 PSI Make/Break

Used in applications requiring a medium oil pressure threshold for alarm or shutdown activation.

Fuel & Oil Pressure Switch – 27 PSI Make/Break

Provides high-threshold protection for critical applications, ensuring that any significant oil pressure drop is detected immediately.

Gauges for Oil System Monitoring

Available in mechanical and electrical configurations for precise oil pressure readings.

-

Mechanical Gauges – Standard and alarm-equipped versions for direct engine monitoring.

-

Electrical Gauges – Available in both 12V and 24V variants for integration into modern instrument panels.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588