Cummins QSB 6.7 Parts - Rebuild Kit Section

Loading...

Loading... Cummins QSB 6.7 Overhaul Kits and Supporting Components

Engine Specifications & Applications

The Cummins QSB 6.7 is a 6-cylinder, inline diesel engine with a displacement of 6.7 liters (408 cubic inches). It is part of the B Series family and shares a common heritage with the ISB 6.7, but is specifically tailored for industrial, marine, and heavy equipment use. Featuring a high-pressure common rail fuel system, electronic controls, and robust internal components, the QSB 6.7 offers enhanced performance and reliability in demanding environments.

Key Applications:

-

Marine auxiliary and propulsion systems (including gensets and workboats)

-

Agricultural equipment (tractors, sprayers)

-

Construction machinery (excavators, dozers, loaders)

-

Stationary industrial generators and compressors

Cummins QSB 6.7 engines are built for consistent output under heavy loads. These engines are known for their low noise, quick throttle response, and long operational life when maintained with quality parts and overhaul practices. For proper rebuild planning, always reference the engine’s CPL (Control Parts List) number. Common QSB 6.7 CPLs include: 426, 427, 656, 1584, 1610, 1629, 2605, 4961, 8466, 8510, 8611, 8615, and 8733.

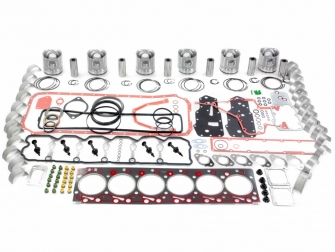

Overhaul Kits for Cummins QSB 6.7

Diesel Pro Power provides CPL-specific overhaul kits for the Cummins QSB 6.7, ensuring compatibility with piston specifications, compression ratios, and gasket dimensions. These rebuild kits are intended for standard-size rebuilds using one-piece pistons, which offer reduced friction and superior durability.

Overhaul Kit for Cummins QSB 6.7 Compatible with CPLs 426, 427, 656, 1584, 1610, 1629, 2605, 4961, 8466, 8510, 8611, 8615, 8733

Kit Contents:

-

One-piece pistons (standard size)

-

Piston rings (matched to bore)

-

Cylinder liners or in-block bore prep options

-

Main bearings (standard size)

-

Rod bearings (standard size)

-

Cam bearings (if required)

-

Upper gasket set (including head gasket)

-

Lower gasket set

Compression Ratio: Most QSB 6.7 engines using these CPLs operate with a compression ratio between 17.3:1 and 17.5:1. This high compression improves combustion efficiency, resulting in more torque and better fuel economy.

Understanding Compression Ratio

Compression ratio refers to how tightly the air-fuel mixture is compressed within the combustion chamber before ignition. Higher compression increases power and fuel efficiency but requires durable piston design and quality gaskets to handle increased stress. For this reason, matching your rebuild kit to the correct CPL number is critical to avoid premature wear or misfiring.

When to Rebuild Your QSB 6.7

There are many signs a Cummins QSB 6.7 engine needs an overhaul. These engines are known for longevity, but operating under heavy loads or with irregular maintenance can lead to gradual degradation.

Common Symptoms:

-

High oil consumption

-

Decreased compression or power

-

Excessive exhaust smoke (white, blue, or black)

-

Engine overheating

-

Oil contamination in coolant or vice versa

-

Cylinder liner cavitation or pitting

-

Blow-by gases escaping through the crankcase breather

If you observe these issues consistently, a full rebuild with a properly matched overhaul kit is the best course of action.

Supporting Components for QSB 6.7 Rebuilds

A complete rebuild often includes replacement of additional wear components beyond pistons and bearings. Below is a breakdown of essential supporting parts compatible with Cummins QSB 6.7 engines.

Piston Cooling Nozzles

Function: Directs a fine spray of oil to the underside of each piston to regulate operating temperature and prevent piston scuffing or ring damage.

-

Required: One per cylinder

-

Critical for engines in marine and industrial service with long-duty cycles

Front Crankshaft Seal Kit

-

Viton or silicone-based crank seal

-

Optional wear sleeve to refresh sealing surface

-

Helps eliminate oil leaks at the gear housing front

Rear Crankshaft Seal Kit

Contents:

-

Double-lip seal construction for high-pressure sealing

-

Wear sleeve

-

Fits engines with wet clutch housings, common in industrial applications

Installation Notes:

-

Always inspect the crankshaft journal for pitting or scoring

-

Replace any damaged alignment pins

-

Use alignment and press tools for seal installation to avoid distortion

Service Tools to Simplify Rebuilds

Having the right tools ensures efficient and accurate rebuilds while reducing risk of damage.

Feeler Gauge Set (0.002" to 0.025")

Used to measure valve lash and ensure proper valve clearance during head installation. These measurements are essential for fuel efficiency and longevity.

Piston Ring Assembly Tool

Enables safe and uniform piston ring installation without damaging the rings or pistons. This is a must-have when installing new rings in tight cylinder bores.

Fuel Filter Removal Wrench

Compatible with spin-on style fuel filters on Cummins B, ISB, and QSB platforms. Reduces the risk of crimping or damaging filter housings during removal.

Oil Filter Removal Wrench

Adjustable steel-band wrench that grips oil filters securely. Compatible with Cummins and Caterpillar filters across a wide range of engines.

Filtration Components for QSB 6.7

Filters must always be replaced during a rebuild. Clogged or worn filters can restrict oil or fuel flow and damage new components.

Fuel Filter

Specifications:

-

Thread: M16 x 1.5"

-

Diameter: ~2.8"

-

Height: ~4.6"

-

Purpose: Removes contaminants from fuel to protect the high-pressure injection system

Fuel Filter & Water Separator

Specifications:

-

Thread: M16 x 1.5" - 6H INT

-

Diameter: ~3.0"

-

Height: ~5.6"

-

Purpose: Filters diesel and removes water to prevent injector damage and corrosion

Spin-On Oil Filter

Specifications:

-

Outside Diameter: ~3.6"

-

Height: ~5.3"

-

Thread: 1-16 UN

-

Purpose: Traps carbon, sludge, and metallic debris circulating in engine oil

Cooling System Maintenance

Radiator Cleaner

Used after a full rebuild to clean out scale, rust, or old coolant residue from the radiator and internal passages. Helps maintain proper operating temperature and prevents hot spots in the cylinder head.

Temperature Switch

Operation: Activates at ~205°F

Thread Size: 1/2" NPT

Connects to alarm systems or electric fans. Especially important in marine installations without an ECM-controlled fan.

Electrical & Mechanical Gauges

Monitor engine conditions in real-time, especially in non-electronic QSB setups.

Gauge Types:

-

Oil Pressure Gauges

-

Coolant Temperature Gauges

-

Voltage Gauges (12V & 24V)

-

Gauges with alarm systems for visual/audible warnings

Use mechanical gauges where electronic signals are not available. Electrical gauges are ideal for fully integrated dashboards or control panels.

Why Trust Diesel Pro Power for Your QSB 6.7 Overhaul?

With over 40,000 satisfied customers, Diesel Pro Power is one of the most trusted names in diesel engine parts and rebuild kits. Here’s why professionals and DIYers choose us:

-

CPL-Specific Kits: No guessing. Each kit matches Cummins specifications for your exact CPL number.

-

Fast Shipping: We stock our kits and ship quickly to ensure you’re back up and running fast.

-

Global Reach: Shipping to over 180 countries with full bilingual support (English & Spanish).

-

OEM-Quality Parts: Our components match or exceed original standards.

-

Expert Support: Diesel Pro’s techs are available to guide you through product selection and installation best practices.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588