Cummins QSB 7.0 Parts - Crankshaft Section

Loading...

Loading... Cummins QSB 7.0 Crankshaft & Rotating Assembly Components

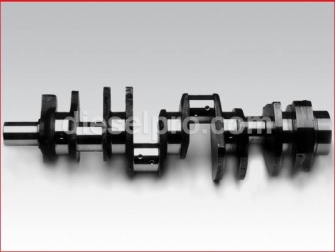

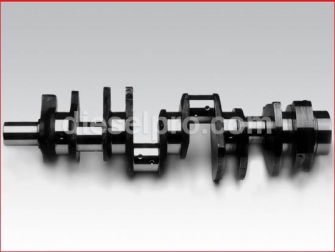

The crankshaft in the Cummins QSB 7.0 is the primary rotating element that transforms the linear motion of the pistons into rotational power. It drives the flywheel, the transmission, and all auxiliary components connected to the engine. In a marine or industrial setting, the QSB 7.0 crankshaft is subjected to high continuous loads, variable RPM cycles, and demanding environmental conditions, making precision, durability, and balance critical to long-term performance.

At Diesel Pro Power, we carry a complete range of QSB 7.0 crankshaft components—brand-new crankshafts, bearing shell sets, front and rear seal kits, and vibration dampers—each engineered to meet Cummins specifications for strength, tolerance, and fit.

New Crankshafts for Cummins QSB 7.0

A crankshaft replacement in the QSB 7.0 restores the rotating assembly to like-new condition. We supply:

-

QSB 7.0 New Crankshaft (Without Timing Gear) – This precision-machined component arrives ready for installation with the correct main and rod journal sizing for factory oil clearance. Ideal for rebuilds where the original timing gear can be reused.

-

QSB 7.0 New Crankshaft Assembly (With Timing Gear) – Delivered with the timing gear pre-installed, ensuring correct gear mesh and timing alignment without press-fitting. This option reduces installation time and eliminates risk from improper gear installation.

Both options are dynamically balanced to minimize torsional vibration, extending the service life of the bearings, seals, and the crankshaft itself.

Crankshaft Bearing Shell Sets for QSB 7.0

Bearing shells provide the low-friction surface on which the crankshaft spins. Worn or damaged bearings can reduce oil pressure, increase heat, and cause severe engine damage if not replaced.

We offer QSB 7.0 crankshaft shell sets in:

-

Standard Size – For crankshafts that measure within original Cummins tolerances.

-

0.25 mm Oversize – For crankshafts that have been ground 0.25 mm undersize during a rebuild.

-

0.50 mm Oversize – For crankshafts requiring additional journal material removal due to heavy wear.

Each set includes both upper and lower shells for a full engine installation, ensuring even wear distribution and stable oil pressure.

Crankshaft Seal Kits – Front & Rear

Proper sealing at both ends of the crankshaft is essential for keeping the QSB 7.0’s lubrication system leak-free and clean.

-

Front Seal Kits – Available with either a sleeve or a dust shield. These seals prevent oil leakage at the front end of the crankshaft where it interfaces with the timing cover and accessory drives.

-

Rear Seal Kits – Offered for engines with either dry or wet clutch housings. Each kit includes the seal and sleeve, providing a tight, lasting fit to prevent oil loss at the flywheel end.

All seals are made from high-grade, heat-resistant elastomers suitable for continuous marine operation.

Vibration Dampers for Cummins QSB 7.0

The QSB 7.0 uses a vibration damper to absorb torsional vibrations generated during combustion. Without a functioning damper, these vibrations can lead to premature bearing wear, gear misalignment, and crankshaft failure.

We carry QSB 7.0 vibration dampers in two sizes:

-

8.23” Outside Diameter, 4-Bolt – Standard-duty design for balanced vibration control.

-

9.7” Outside Diameter, 4-Bolt – Larger size for additional damping capacity in high-load applications.

Each damper is precision-balanced for smooth operation and protection of the crankshaft under all load conditions.

Why Choose Diesel Pro Power for QSB 7.0 Crankshaft Parts

With over 40,000 satisfied customers worldwide, Diesel Pro Power has built its reputation on delivering reliable marine and industrial engine parts quickly and accurately. For the Cummins QSB 7.0 crankshaft system, we provide:

-

Direct-fit OEM replacements

-

Heavy-duty durability for marine environments

-

Immediate availability to minimize downtime

-

Strict quality control to guarantee accuracy

Tips for Maximizing QSB 7.0 Crankshaft Life

-

Maintain clean engine oil and follow the manufacturer’s oil change intervals.

-

Monitor oil pressure for early signs of bearing wear.

-

Replace seals at the first sign of leakage to protect bearings and journals.

-

Inspect the vibration damper regularly for cracks or delamination.

-

Follow Cummins torque specs during assembly to prevent distortion.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588