Cummins QSB 7.0 Parts - Oil Section

Loading...

Loading... Oil Pump & Lubrication Components for Cummins QSB 7 Engines

The Cummins QSB 7.0 engine is a versatile, high-performance diesel platform used in marine, industrial, and heavy-duty power generation applications. A critical component in its reliability is the lubrication system—designed to ensure every moving part receives a consistent flow of clean oil under the most demanding operating conditions.

In this section, we detail the oil pump assemblies and related lubrication components available for the QSB 7, including differences between front and rear gear train configurations, associated gaskets, oil pans, coolers, filters, and pressure control devices. All components are engineered to meet or exceed Cummins OEM specifications for fit, durability, and performance.

Understanding the Role of the Oil Pump in the QSB 7

The oil pump in the Cummins QSB 7 is responsible for creating the pressure that circulates lubricating oil through the crankshaft bearings, camshaft bearings, connecting rods, piston cooling jets, turbocharger, and valvetrain.

Key functions of the QSB 7 oil pump include:

-

Maintaining consistent oil pressure across a wide range of RPMs and load conditions.

-

Feeding piston cooling nozzles to control combustion temperatures.

-

Supplying the turbocharger bearings with clean, pressurized oil to prevent premature wear.

-

Supporting the entire hydraulic lubrication circuit for engine longevity in marine and industrial duty cycles.

Front Gear Train Oil Pumps for QSB 7

Some QSB 7 engines are configured with the oil pump mounted in the front gear train. In these designs, the pump is driven by a helical or straight-cut gear set, depending on CPL (Control Parts List) specification.

Front Gear Train with Helical Teeth

-

Gear Design: Pinions have 23/24 helix teeth for smoother operation and reduced gear noise.

-

Application: Preferred in certain CPL configurations optimized for quiet operation in enclosed marine engine rooms.

-

Benefits: Reduced vibration, improved oil pressure stability, and enhanced gear life.

Front Gear Train with Straight Teeth

-

Gear Design: Pinions feature 22/24 straight teeth, offering robust torque transfer.

-

Application: Found in select CPLs designed for industrial or open marine deck machinery where maximum durability is prioritized over minimal gear noise.

-

Benefits: High mechanical efficiency, strong load-carrying capacity, and easier serviceability.

Rear Gear Train Oil Pumps for QSB 7

In other QSB 7 configurations, the oil pump is located at the rear gear train. This design is often selected for certain marine propulsion packages where the engine’s front area is dedicated to auxiliary drives, or where service access to the rear of the engine is preferable.

Rear Gear Train with Straight Teeth

-

Gear Design: Pinions have 22/24 straight teeth.

-

Application: Supports rear-mounted auxiliary equipment while maintaining steady oil flow under heavy load.

-

Benefits: Direct gear drive ensures reliability, especially in continuous-duty marine propulsion or generator set operation.

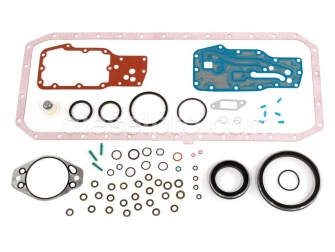

Lower Gasket Sets for QSB 7

A complete lower gasket set includes all the seals and gaskets needed for servicing the engine’s lubrication system, oil pan, and related lower-end components.

Typical contents include:

-

Oil pan gasket

-

Oil pick-up tube gasket

-

Rear main seal housing gasket

-

Front crankshaft seal

-

Auxiliary cover seals

Using a complete lower gasket set during overhaul or major service ensures that all sealing points are addressed at once, preventing future oil leaks.

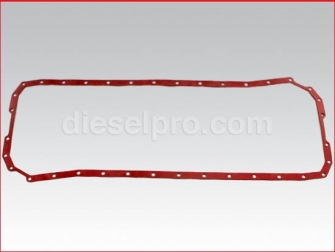

Oil Pan & Oil Pick-Up Tube Gaskets

The oil pan gasket forms the primary seal between the oil pan and the engine block. In marine applications, where engine mounts and hull vibration can be more pronounced, a high-quality gasket is critical for leak prevention.

The oil pick-up tube gasket seals the connection between the oil pick-up tube and the oil pump or block. A compromised pick-up gasket can lead to oil aeration or starvation, which can cause severe engine damage.

Oil Coolers for QSB 7

Oil coolers regulate lubrication oil temperature, preventing overheating under sustained high-load operation.

-

Ideal for general marine propulsion and auxiliary power units.

-

Compact yet efficient heat dissipation.

-

Specifically designed for engines with a rear gear train layout.

-

Allows optimal routing of oil lines in compact engine compartments.

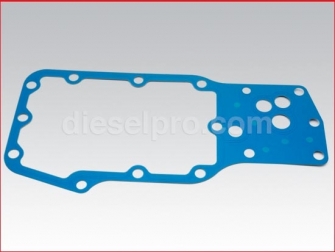

Oil Cooler Gaskets & Seals

Maintaining a proper seal in the oil cooler assembly is vital to prevent oil and coolant cross-contamination. Available options include:

-

Oil cooler core gaskets (standard and metal types for high-pressure applications)

Marine Zinc Anodes for Oil Coolers

Marine QSB 7 installations often include zinc anodes in the oil cooler assembly to protect against galvanic corrosion. These sacrificial anodes are easy to replace and extend the life of both the cooler and other metal components in contact with seawater.

Oil Filtration for QSB 7

Proper oil filtration is essential for protecting high-precision components inside the QSB 7.

-

Designed with high-efficiency filter media to capture fine contaminants.

-

Threaded for quick replacement during routine service.

Oil Filter Removal Tools

For tight engine spaces—common in marine engine rooms—specialized oil filter removal wrenches make servicing easier and prevent damage to filter housings.

Fuel & Oil Pressure Switches

Pressure switches monitor oil pressure and send electrical signals to alarms or shut-down circuits if pressure drops below a safe threshold. Available in multiple calibration points (5, 10, 20, and 27 PSI), these switches are critical for marine safety compliance.

Gauges for Oil Pressure Monitoring

Accurate monitoring of oil pressure is crucial in both marine and industrial QSB 7 applications. Gauge options include:

-

Mechanical gauges for direct reading

-

Mechanical gauges with alarms for added protection

-

Electrical gauges in 12-volt and 24-volt configurations for integration with vessel or machinery control panels

Maintenance Recommendations for the QSB 7 Lubrication System

-

Inspect oil pump gears at every major service interval for wear or pitting.

-

Replace gaskets and seals whenever components are removed to maintain system integrity.

-

Change oil filters at manufacturer-recommended intervals or more frequently in severe duty.

-

Monitor oil pressure trends—gradual drops may indicate pump wear or internal leakage.

-

Service marine zinc anodes regularly to prevent oil cooler corrosion.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588