Cummins QSB 7.0 Parts - Rebuild Kit Section

Loading...

Loading... Cummins QSB 7.0 Overhaul Kits and Supporting Components

Engine Specifications & Applications

The Cummins QSB 7.0 engine is a high-performance, electronically controlled, 6-cylinder diesel powerplant with a 7.0-liter displacement. Designed as part of Cummins’ Quantum System, the QSB 7.0 combines rugged mechanical reliability with advanced electronic control. It delivers exceptional power density and torque output while maintaining fuel efficiency and lower emissions.

This engine is commonly found in:

-

Heavy-duty industrial machinery (excavators, loaders, cranes)

-

Agricultural tractors and harvesters

-

Marine auxiliary systems

-

Power generation units

-

Hydraulic pumping and oilfield applications

The QSB 7.0 platform typically features a rear gear train configuration and high-pressure common rail fuel system. Engines matched to specific CPL (Control Parts List) numbers must be rebuilt with precisely compatible overhaul kits to maintain performance and emissions compliance.

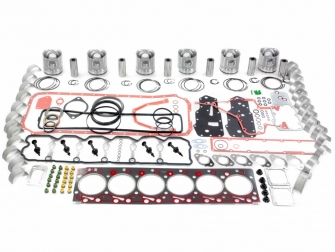

Overhaul Kits for Cummins QSB 7.0

Diesel Pro Power offers overhaul kits designed specifically for the Cummins QSB 7.0 engine platform. These kits include the most critical wear components for a complete in-frame or out-of-frame rebuild. All parts are manufactured to OEM specifications or higher, ensuring a reliable restoration of power and longevity after overhaul.

QSB 7.0 Overhaul Kit – Compatible with Rear Gear Train CPLs

This rebuild kit is compatible with QSB 7.0 engines configured with a rear gear train and CPL numbers including 426, 427, 656, 1584, 1610, 1629, 2605, 4961, 8466, 8510, 8611, 8615, and 8733.

Included Components:

-

1-piece aluminum or steel pistons (as specified by CPL)

-

Premium piston rings

-

Connecting rod bearings

-

Main bearings

-

Camshaft bearings (as required)

-

Full upper and lower gasket sets (including MLS or composite head gasket)

-

Cylinder liners or bore prep supplies (if applicable)

Compression Ratio: Most QSB 7.0 engines feature compression ratios in the range of 17.0:1 to 17.3:1, depending on CPL.

Why Compression Ratio Matters

Compression ratio affects the combustion pressure, thermal efficiency, and overall torque characteristics of the engine. A higher compression ratio increases power output and fuel economy but also results in greater stress on the pistons, rings, and gaskets. That’s why matching the correct piston bowl geometry and head gasket thickness to your CPL number is critical.

When to Rebuild Your Cummins QSB 7.0

Many operators wait too long to rebuild, leading to greater internal damage and cost. Here are key signs it’s time for an overhaul:

Symptoms Indicating an Overhaul is Needed

-

Significant oil consumption

-

Loss of power or uneven acceleration

-

Low cylinder compression or blow-by

-

Coolant or oil cross-contamination

-

Engine knocking or vibration during load

-

Persistent exhaust smoke (white, blue, or black)

Rebuild Timing Based on Hours

Typical QSB 7.0 engines require a full overhaul every 10,000 to 15,000 hours, depending on maintenance history, fuel quality, and operating conditions.

Essential Supporting Components for Your Rebuild

Beyond pistons and bearings, a complete engine rebuild should always include updated filtration, sealing, and cooling system components. These peripheral parts are essential to the long-term success of your overhaul.

Piston Cooling Nozzles

Function: These spray pressurized oil on the underside of each piston, cooling the crown and lubricating the rings.

Why Replace Them? Over time, nozzles can become clogged or damaged, reducing their effectiveness. This can lead to piston overheating, ring scuffing, and eventual failure.

Installation Note: Replace one nozzle per piston during overhaul and inspect oil galleries for cleanliness.

Crankshaft Seal Kits

Sealing the front and rear of the crankshaft is essential to prevent oil leaks and maintain oil pressure.

-

Includes the seal and wear sleeve

-

Ensures a tight seal at the timing cover

-

Prevents oil seepage and contamination of the accessory drive

-

Includes a double-lip seal and installation sleeve

-

Designed for engines with wet clutch housings

-

Must be installed with precision alignment tools to prevent future leaks

Precision Tools for Proper Reassembly

Professional engine reassembly requires precise measuring and installation tools to avoid costly mistakes. Diesel Pro Power offers the following tools commonly used during QSB 7.0 rebuilds:

Feeler Gauge (.002" to .025")

-

Used to calibrate valve lash

-

Essential during cylinder head and camshaft reinstallation

Piston Ring Assembly Tool

-

Prevents ring damage during piston installation

-

Compatible with all B, ISB, and QSB engine series

Fuel Filter Removal Wrench (3-7/16" to 3-3/4")

-

Designed to grip standard diesel fuel filters without deformation

-

Essential for proper maintenance during and after engine break-in

Oil Filter Removal Wrench (4-21/32" to 5-5/32")

-

Compatible with Cummins and Caterpillar filters

-

Ensures secure grip even on tight or weathered filters

Filtration System Maintenance

Installing fresh filters is critical after an overhaul to prevent immediate wear from contaminants and debris.

Fuel Filter

-

Protects injectors and high-pressure pump from particulates

-

M16 x 1.5" thread

-

Should be primed before first engine start after rebuild

Fuel Filter with Water Separator

-

Combines particulate and water removal in one unit

-

Protects fuel system from microbial growth and rust

-

Drain water trap regularly for best performance

Spin-On Oil Filter

-

Removes combustion soot, metal particles, and debris

-

Use manufacturer-recommended break-in oil and change after first 50 hours

Cooling System Components

After rebuilding, thoroughly clean the cooling system to avoid scale and deposit re-entry into the new engine.

Radiator Cleaner

-

Designed for aluminum, copper, and brass radiators

-

Removes rust, scale, and oil contamination

-

Use before adding fresh coolant

Temperature Switch

-

Activates engine fan or alarm at 205°F

-

1/2" NPT thread

-

Ensures early warning for overheating or coolant system issues

Gauges for Monitoring After Rebuild

Whether mechanical or electric, high-quality gauges are necessary to monitor your rebuilt engine’s performance.

Available Options:

-

Oil Pressure Gauges – Detect loss of oil pressure or pump failure

-

Coolant Temperature Gauges – Provide real-time engine temperature readout

-

Voltmeter Gauges – Ensure alternator output is charging correctly

-

Alarm Gauges – Trigger visual or audible alarms for out-of-range conditions

Choose 12V or 24V gauge sets depending on your electrical system configuration.

Break-In Best Practices for QSB 7.0 Rebuilds

First 50 Hours

-

Use manufacturer-approved break-in oil (non-synthetic)

-

Vary engine RPM and load conditions

-

Avoid long idle periods

After First Service Interval

-

Replace all filters

-

Switch to full synthetic if desired

-

Retorque head bolts and inspect valve lash

Why Buy From Diesel Pro Power?

With over 40,000 satisfied customers globally, Diesel Pro Power is a trusted source for high-quality Cummins engine rebuild kits and components.

What Sets Us Apart

-

CPL-matched kits for perfect compatibility

-

Fast shipping across the U.S. and internationally

-

Expert customer service in English and Spanish

-

Extensive inventory of rare Cummins QSB parts

-

Support for both marine and industrial applications

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588