Parts for Detroit Diesel 12V71 Non-Turbo - Exhaust Section

Loading...

Loading... Parts for Detroit Diesel 12V71 Non-Turbo – Exhaust Section

The Detroit Diesel 12V71 Non-Turbo engine is one of the most legendary power units in the Series 71 family. Known for its distinctive sound, outstanding reliability, and two-stroke design, this 12-cylinder V-configuration engine has powered vessels, heavy equipment, and industrial installations for decades. A major part of keeping this engine operating efficiently lies in maintaining its exhaust system — a complex assembly designed to manage heat, backpressure, and emissions while also protecting the engine’s components from corrosion and damage.

Diesel Pro Power provides a full catalog of exhaust components for the 12V71 Non-Turbo engine, including marine water-cooled manifolds, flanges, gaskets, elbows, insulation materials, and flexible exhaust hoses. Each part listed below is engineered or remanufactured to meet or exceed OEM specifications, ensuring long-term reliability in the most demanding marine and industrial environments.

Detroit Diesel Marine Water-Cooled Manifold for 12V71

The marine water-cooled exhaust manifold is the core of the engine’s exhaust system. For the Detroit Diesel 12V71 Non-Turbo, the manifold directs hot exhaust gases away from each cylinder bank while circulating cooling water through internal jackets. This reduces exhaust temperatures, prevents overheating of nearby components, and minimizes thermal stress on the cylinder heads.

Diesel Pro Power offers new marine manifolds that feature precision-machined flanges, corrosion-resistant interiors, and one-inch threaded fittings for easy installation. These manifolds are ideal for repowers, restorations, or maintenance on yachts, tugs, fishing boats, and generator sets. Properly sealed and installed, a new manifold can dramatically extend engine life and improve exhaust flow consistency, especially in long-running applications.

Head-to-Manifold Gaskets for Series 71 Engines

Every connection between the cylinder head and the exhaust manifold requires a high-temperature gasket designed to withstand constant expansion and contraction cycles. Diesel Pro Power carries both standard 6-71 / 12V71 head-to-manifold gaskets and the Series 71-92 cross-compatible gasket types, giving technicians flexibility depending on the configuration of the engine.

Each gasket is manufactured from reinforced graphite composite material, offering excellent sealing performance against heat and vibration. The gaskets prevent exhaust leaks that could reduce performance or cause carbon buildup around the head ports. On the 12V71 Non-Turbo engine, ensuring a perfect seal is especially important because of the engine’s two-stroke scavenging cycle — any leak in the exhaust path can disrupt the pressure balance required for optimal air exchange.

Marine Manifold Flange and Gasket Assemblies

The marine manifold flange provides the secure mechanical connection between the manifold and the exhaust outlet or riser system. Diesel Pro Power supplies flanges machined to 4-inch NPT thread size, suitable for both port and starboard manifolds.

Complementing these are marine manifold flange gaskets, which provide sealing at the junction where cooling water exits or where the manifold attaches to the exhaust piping. Each gasket features precise outer and inner diameters to match Detroit Diesel manifold specifications, ensuring a tight fit and leak-free performance even under high heat and water pressure.

These flanges and gaskets are essential components in marine applications where saltwater corrosion and vibration are constant challenges. Using high-quality replacements from Diesel Pro Power ensures the integrity of your exhaust cooling system and reduces the risk of leaks that could cause steam or exhaust intrusion into the engine room.

Manifold Insulation Tape – Heat Protection and Safety

The manifold insulation tape is designed to wrap around exhaust manifolds, elbows, and piping to maintain lower surface temperatures. Diesel Pro Power offers both 3-inch-wide and 4-inch-wide insulation rolls, each 100 feet long and ⅛-inch thick.

Proper insulation plays a vital role in protecting nearby wiring, hoses, and fiberglass components from excessive heat. In engine rooms with limited airflow — common in marine vessels — reducing radiant heat improves comfort and safety for maintenance personnel and enhances overall cooling efficiency.

Diesel Pro Power’s insulation tape resists fraying, withstands continuous temperatures over 1000 °F, and remains flexible for easy installation around bends and fittings. Wrapping manifolds and risers with insulation also helps preserve exhaust energy, which can improve scavenging efficiency on naturally aspirated two-stroke engines like the 12V71 Non-Turbo.

Manifold Mounting Hardware: Studs, Crabs, Washers, and Nuts

A durable exhaust manifold requires equally durable mounting hardware. Diesel Pro Power provides complete fastener solutions, including:

-

Manifold studs – Precision-machined 7⁄16-inch × 2.1-inch studs engineered to maintain clamping force under thermal cycling.

-

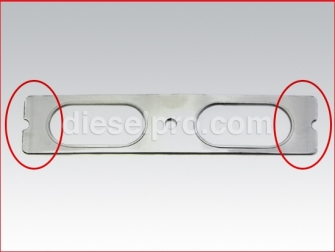

Manifold crabs (clamps) – These specialized brackets hold adjoining manifold sections together, maintaining even pressure along the gasket surface.

-

Washers and nuts – Manufactured from high-tensile steel to resist loosening from vibration or heat expansion.

Replacing corroded or fatigued hardware prevents warping and leaks, which are common issues in older engines subjected to years of service. Every component in this set is designed for the Detroit Diesel Series 71 architecture and ensures a proper fit without modification.

Water Outlet Plates, Threaded Plates, and Gaskets

The marine manifold water outlet plate and its accompanying gasket are small yet crucial elements that maintain water circulation integrity. The outlet plate seals the coolant path at the end of the manifold, while the threaded plate (3⁄4-inch NPT) provides connection points for hoses or elbows. Diesel Pro Power’s plates are built from corrosion-resistant alloys and machined to tight tolerances for leak-free installation.

The associated water-outlet gasket is made from high-density composite material designed to endure constant temperature changes and exposure to antifreeze or seawater mixtures. Together, these components prevent coolant loss and protect the manifold’s internal passages from pitting or erosion.

Marine Manifold Elbows – 90-Degree and 45-Degree Fittings

To route exhaust gases and cooling water efficiently within tight marine engine compartments, Diesel Pro Power supplies both 90-degree and 45-degree elbows in standard ¾-inch and 1-inch thread sizes.

-

The 90-degree elbows are ideal for installations where space is limited and vertical or horizontal transitions are necessary.

-

The 45-degree elbows allow smoother bends that reduce exhaust restriction and improve gas flow.

Each elbow is cast from heavy-duty bronze or equivalent marine-grade material to resist saltwater corrosion. Properly installed elbows maintain even exhaust flow from both banks of the 12V71 engine, ensuring balanced backpressure and optimal performance.

Gasket for Marine Manifold Flange Spacer

Another vital sealing element is the flange spacer gasket, designed to sit between exhaust spacer rings and connecting flanges. This gasket absorbs vibration, compensates for slight surface irregularities, and maintains airtight sealing under thermal expansion. Diesel Pro Power’s flange spacer gaskets are cut with precision and constructed from heat-resistant composite material suitable for extended service in continuous-duty engines.

Muffler Caps – Protection for Idle Engines

When the engine is shut down, especially on vessels moored outdoors, it’s important to prevent water or debris from entering the exhaust outlets. Diesel Pro Power offers muffler caps in several standard diameters — 4½-inch, 5-inch, and 6-inch sizes — to suit various exhaust configurations.

These caps are fabricated from stainless or galvanized steel with smooth-pivot hinges, allowing them to close automatically when the engine stops. They’re especially valuable for boats operating in rough or wet conditions, ensuring that rain or back-spray doesn’t reach the exhaust system. Maintaining clean, dry exhaust passages prevents rust and carbon buildup inside the manifold and piping.

Flexible Metal Exhaust Hoses – Absorbing Vibration and Movement

Marine engines experience constant motion and vibration, which can stress rigid exhaust piping. The flexible metal exhaust hoses offered by Diesel Pro Power are engineered to absorb these movements, protecting manifolds and joints from fatigue.

Available in 4-inch × 18-inch, 6-inch × 18-inch, and 8-inch × 18-inch dimensions, each hose is made from corrugated stainless steel and designed to handle high exhaust temperatures while maintaining airtight flexibility.

By installing flexible connectors between the manifold and muffler or riser, operators reduce the likelihood of cracks or leaks in welded sections. This not only improves reliability but also helps dampen engine vibration transmitted through the hull or mounting structure — a key comfort factor in passenger vessels and yachts.

Temperature Switch for Detroit Diesel 12V71 Applications

A temperature switch is essential for monitoring and safeguarding engine operating conditions. Diesel Pro Power’s temperature switch for Detroit Diesel Series 71 engines is calibrated to close at 205 °F, triggering alarms or shutdowns when coolant temperature exceeds safe limits.

With a ½-inch NPT thread, it installs easily in manifold or cylinder-head ports. Regular replacement of aging sensors helps maintain reliable engine protection systems, especially in older 12V71 installations where original wiring or gauges may have been modified.

Detroit Diesel Green Engine Paint

To complete maintenance or restoration work, Diesel Pro Power offers authentic Detroit Green engine paint formulated for heat resistance and corrosion protection. This color not only restores the classic appearance of the 12V71 engine but also adds a durable coating that resists oil and fuel staining. Available for ground shipment within the U.S. and Canada, it’s a popular finishing touch for professional rebuilders and enthusiasts alike.

Mechanical and Electrical Gauges for Exhaust and Cooling Monitoring

In addition to physical exhaust components, Diesel Pro Power stocks a variety of mechanical and electric gauges for monitoring temperature, pressure, and system performance.

-

Mechanical gauges provide direct, reliable readings without external power.

-

Electrical gauges are available in 12-volt and 24-volt versions with optional alarm outputs for integrated control panels.

Installing accurate gauges ensures real-time awareness of exhaust temperature and cooling system status — critical parameters for maintaining the 12V71 Non-Turbo engine’s efficiency.

Why Buy Detroit Diesel 12V71 Non-Turbo Exhaust Parts from Diesel Pro Power

Trusted Global Supplier with Proven Experience

Diesel Pro Power has been serving the worldwide Detroit Diesel community for decades, earning the trust of over 40,000 satisfied customers across marine, industrial, and transportation sectors. With a focus on legacy two-stroke engines such as the 12V71, the company ensures that owners and operators can continue maintaining these legendary machines long after OEM production ceased.

Genuine Quality and Technical Expertise

Every manifold, gasket, and fitting supplied by Diesel Pro Power is either OEM or precision-remanufactured to match factory specifications. Parts are inspected for dimensional accuracy, material quality, and surface finish to guarantee a perfect fit and reliable operation. The company’s technical team offers expert guidance for identifying the correct components based on serial numbers, configurations, and application types.

Fast Shipping and Global Availability

Diesel Pro Power operates a fully stocked distribution center that enables same-day shipping on most orders. International customers benefit from door-to-door delivery with real-time tracking, ensuring that vessels and equipment minimize downtime. The company’s logistics expertise extends to remote ports and industrial sites worldwide, making it the preferred source for Detroit Diesel replacement parts.

Comprehensive Product Coverage

The 12V71 Non-Turbo exhaust system is only one section of Diesel Pro Power’s vast catalog. Customers can easily find complementary products such as cylinder kits, fuel injectors, blowers, turbochargers (for upgraded models), water pumps, and complete gasket sets — all organized by engine model for quick selection.

Dedicated Customer Support

Whether you’re a marine engineer refitting a commercial vessel or a hobbyist restoring a classic Detroit Diesel engine, Diesel Pro Power provides personalized customer service. Representatives are available via phone or online chat to assist with installation advice, torque specifications, and compatibility questions.

Confidence and Longevity

By purchasing from Diesel Pro Power, customers gain more than replacement parts — they gain peace of mind. Each product is backed by a warranty and the assurance that it has been tested to perform in the demanding conditions typical of Detroit Diesel two-stroke engines.

Maintaining the Detroit Diesel 12V71 Non-Turbo Exhaust System

Regular inspection of the exhaust system is vital for preventing issues that can compromise performance. Key maintenance tips include:

-

Check for leaks or soot marks around manifold joints and gaskets.

-

Inspect insulation tape for wear or fraying, and replace it to maintain safety.

-

Examine flexible hoses for signs of corrosion or fatigue.

-

Clean and repaint manifolds with Detroit Green engine paint to inhibit rust.

-

Test temperature switches and gauges periodically to ensure proper functionality.

By following these maintenance practices and using high-quality components from Diesel Pro Power, operators can preserve the legendary reliability of their 12V71 engines for decades to come.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588