Parts For Detroit Diesel 12V92 Turbo - Gasket Section

Loading...

Loading... -

-

-

-

-

Detroit Diesel Inspection Cover Gasket for Series V71, V92 and for 6V53, 8V53 new style

8923792

.

Price: $ 8.61 -

Detroit Diesel Front End Plate Gasket for Series V71 & V92

5144901

Located between the block and end platePrice: $ 20.15 -

Detroit Diesel Rear Crankshaft seal

5114335

Rear for 271, 371, 471, 671,6V71, 8V71, 12V71, 8V53 and Front for 16V71, 12V92, 16V92. - Standard - Single Lip

Price: $ 33.18 -

Detroit Diesel Rear Crankshaft seal.

5197860

Rear - Oversize - Single Lip for 271, 371, 471, 671, 6V71, 8V71, 8V53 and Front for 16V71,12V92, 16V92 Engines

Price: $ 45.45 -

Detroit Diesel Crankshaft seal for 16V71, 6V92, 8V92, 12V92 , 16V92

8929750

Rear - Standard - Single Lip - Universal rotation (right or left)

Price: $ 214.19 -

Detroit Diesel crankshaft seal for 6V92, 8V92, 12V92 and 16V92 engines

5135150

Rear - Standard - Double lip

Price: $ 108.81 -

Detroit Diesel crankshaft seal for 6V92, 8V92, 12V92 and 16V92 engines

5198159

Rear - Oversize - Double lip - Universal rotation

Price: $ 192.85 -

Detroit Diesel crankshaft Seal for 6V92, 8V92, 12V92 and 16V92 engines

23501544

Rear - Oversize - Single lip - Right hand rotation

Price: $ 53.34 -

Detroit Diesel Crankshaft seal, for 16V71, 6V92, 8V92, 12V92 , 16V92 engines

23501545

Rear - Oversize - Single lip - Left hand rotation

Price: $ 95.22 -

Detroit Diesel Sleeve seal

5197159

Oversize - Rear for 71 series and Front for 16V71, 12V92 and 16V92 engines.

Price: $ 55.43 -

Detroit Diesel Sleeve crankshaft seal for 16V71, 6V92, 8V92, 12V92 , 16V92 engine

23507226

Rear - Oversized

Price: $ 27.93 -

Detroit Diesel Head gasket for 6V92 and 12V92

5199673

6V92 requires 2 kits

12V92 requires 4 kits

Price: $ 70.14 -

Detroit Diesel Rocker cover gasket kit, for 3-71, 6V71, 6V92, and 12V92

5149510

For use with aluminum rocker covers. New stylePrice: $ 70.50 -

-

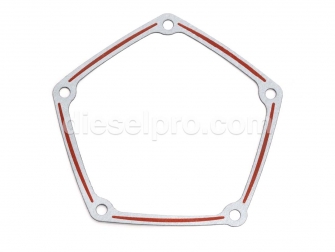

Detroit Diesel Flywheel Housing Gasket for V71 and V92

5144875

Gasket located between end plate and flywheel housingPrice: $ 30.84 -

-

-

Allison Flywheel Gasket for Marine Transmission M and MH - SAE 2 (Most Common)

29503155

Use when engine housing size is the same as transmission

Price: $ 102.60 -

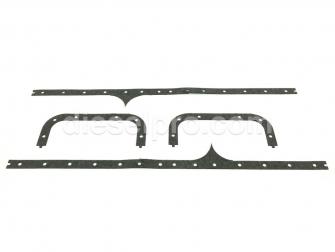

Detroit Diesel Blower installation kit for 12V71, 12V92 Turbo

5149642

Covers two blowers

Price: $ 128.56 -

-

-

Detroit Diesel Striker Plate Gasket for 6V71, 6V92, 12V71 and 12V92

5145235

Gasket between blower and Striker PlatePrice: $ 15.19 -

-

Detroit Diesel Turbo riser gasket

8923492

Inner width 2”, Inner Length 3.75”, Outer width 3.75”, Outer Length 5.5”Price: $ 9.08 -

762 Hi-Temperature jointing compound for Detroit Diesel and Cummins turbos

762

225 gm tube - Temp range 550C to 760CPrice: $ 188.19 -

-

-

Detroit Diesel Gasket for marine manifold 12V71, 6V92, 8V92, 12V92, 16V92

23515227

Outside diameter 6.80", inside diameter 4.25"Price: $ 79.86 -

Detroit Diesel Intercooler Gasket for 671,12V71,12V92

5149433

Use 2 of this gasket per intercoolerPrice: $ 37.46 -

Detroit Diesel Intercooler Gasket for 671, 12V71, 12V92

5147423

Use 2 of this gaskets per intercoolerPrice: $ 14.13 -

Detroit Diesel Intercooler Gasket for Engine 671, 12V71, 12V92

23511698

4 gaskets per Intercooler

Price: $ 74.39 -

Oil pan gasket for Detroit Diesel engine 12V92

8920608

Between the block and the cast iron oil panPrice: $ 23.76 -

-

-

-

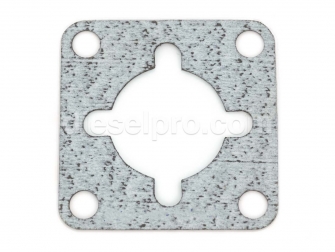

Detroit Diesel Gasket for Hydraulic Governor

23509675

Gasket between Governor and DrivePrice: $ 5.50 -

Oil cooler installation kit for Detroit Diesel

2COOLERS-INS-K

For Double oil coolersPrice: $ 242.09 -

-

-

-

-

-

-

-

Detroit Diesel Gasket, marine manifold flange spacer

5101914

Outside diameter 6.25", inside diameter 3.50"Price: $ 69.50 -

Detroit Diesel Marine exhaust manifold gasket for engine JT 92

23516686

Outside diameter 6.50", inside diameter 4.28"Price: $ 69.78 -

-

Green Paint for Detroit Diesel Engines

26006

Available for ground shipping only in USA and CanadaPrice: $ 12.46 -

-

Gasket Spray -High Tack Sealant (Hold & Seals Cut Gaskets)

99MA

For Detroit Diesel & Cummins engines. Available for ground shipping only in USA and CanadaPrice: $ 25.67 -

3H Gasket Maker

3H

For Detroit Diesel & Cummins engines. Available for ground shipping only in USA and CanadaPrice: $ 17.46 -

-

-

-

-

Gasket Maker - Ultra Blue RTV Silicone Sensor Safe

77BR

For Detroit Diesel & Cummins enginesPrice: $ 11.03 -

-

Gaskets for Detroit Diesel 12V92 Turbo — Complete Catalog & Technical Guide

The Detroit Diesel 12V92 Turbo engine relies on precise sealing to handle its immense power output, boost pressure, and two-stroke operating environment. Every gasket, seal, and compound in this section has been designed and tested to meet the unique thermal, pressure, and vibration demands of this turbocharged V-12 engine. Below you’ll find a comprehensive, system-by-system breakdown of all gasket components used on the 12V92 Turbo — focused exclusively on this engine and formatted for clarity, accuracy, and SEO optimization.

Gaskets for Engine Overhaul and Major Interfaces – 12V92 Turbo

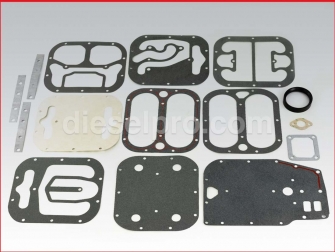

Overhaul Gasket Kit For The Detroit Diesel 12V92 Turbo Engine

A complete overhaul gasket kit for the 12V92 Turbo provides every major sealing component required during a rebuild or in-frame overhaul.

-

Purpose: Restores full engine integrity when multiple systems (heads, liners, oil pan, turbo, and cooling circuits) are opened.

-

Coverage: Includes head, block, blower, intercooler, water manifold, oil system, and accessory gaskets.

-

Usage tip: When rebuilding a 12V92 Turbo, always replace gaskets in sets to maintain balanced compression and sealing uniformity across all twelve cylinders.

Installation advice:

-

Clean every surface thoroughly and chase bolt holes before installation.

-

Match each gasket to its original position and orientation.

-

Follow OEM Service Manual Instructions for torque

Gaskets for Cylinder Head and Upper Engine – 12V92 Turbo

Cylinder Head Gasket Kits For Detroit Diesel 12V92 Turbo Engines

Each 12V92 Turbo requires four head gasket kits to fully reseal the twelve-cylinder layout.

-

Function: Contain high boost combustion gases, separate oil and coolant passages, and withstand the extreme temperatures of turbo operation.

-

When to replace: During any head removal or overheating event.

-

Inspection tip: Check block and head deck flatness using a machinist straightedge — the tolerance must be within factory specification to avoid leaks.

Rocker Cover Gasket Kit For Detroit Diesel 12V92 Engines

This new-style rocker cover gasket kit fits the aluminum valve covers on the 12V92 Turbo.

-

Purpose: Prevents oil mist and blow-by leakage from the top of the engine.

-

When to replace: After valve adjustment, injector setting, or any time rocker covers are removed.

-

Recommendation: Replace sealing grommets and bolts if oil seepage persists after new gaskets are installed.

Gaskets for Blower and Air Inlet System – Detroit Diesel 12V92 Turbo

Blower Installation Gasket Kit For Detroit Diesel 12V92 Turbo

The blower installation gasket kit for the 12V92 Turbo reseals the twin Roots-type blowers that supply air to the two-stroke intake ports.

-

Importance: Any leakage between the blower and the block reduces scavenging efficiency and causes power loss.

-

Includes: Gaskets for blower base, air passages, and end plates.

-

Pro tip: Apply even torque across all bolts and check end plate alignment to prevent rotor binding.

Striker Plate Gasket For Detroit Diesel 12V92 Turbo

This gasket maintains air-tight sealing between the blower and the Stricker plate, ensuring even airflow to each cylinder.

-

Use with: Blower installation gasket kit.

-

Failure signs: Soot or oil streaks around the plate edge, or uneven idle due to air imbalance.

Air Inlet Housing Gasket For Detroit Diesel 12V92 Turbo

The air inlet housing gasket seals the air horn assembly to the blower inlet on the 12V92 Turbo.

-

Purpose: Prevents unmetered air and maintains boost pressure integrity.

-

Symptoms of failure: Hissing sounds under boost, reduced turbo response, or oily residue near the joint.

Gaskets for Turbocharger Interfaces – Detroit Diesel 12V92 Turbo

The turbo riser gasket seals the connection between the turbocharger outlet and the riser manifold.

-

Material: High-temperature composite designed to resist thermal expansion and vibration.

-

Dimensions: Inner width 2”, inner length 3.75”, outer width 3.75”, outer length 5.5”.

-

Installation note: Inspect both flanges for flatness; retorque after first heat cycle.

Turbo Oil Supply and Return Gaskets

These small yet vital gaskets seal the pressurized oil feed and the gravity return from the turbocharger.

-

Function: Keep oil confined to the turbo bearing housing, preventing leaks or starvation.

-

Replacement interval: Whenever the turbo is serviced or replaced.

-

Common issue: Over-tightened bolts deform thin flanges — use a torque wrench to prevent bending.

High-Temperature Jointing Compound

A specialized jointing compound rated between 550°C and 760°C, used for certain high-heat exhaust or turbo connections.

-

Note: Apply sparingly — only where Detroit Diesel specifies a compound rather than a gasket.

-

Not a substitute: This compound complements, not replaces, proper gaskets.

Gaskets for Crankshaft and Rotating Assembly – Detroit Diesel 12V92 Turbo

Rear and Front Crankshaft Seals

The 12V92 Turbo uses precision crankshaft seals at both front and rear ends. These are available in:

-

Single-lip or double-lip (the latter adds a dust lip for marine or dusty environments).

-

Standard or oversize versions (oversize is paired with a sleeve when the crank hub shows wear).

-

Rotation-specific variants (right-hand or left-hand rotation) depending on engine build.

Installation guidelines:

-

Inspect crank sealing surfaces for grooves; replace with an oversize seal and sleeve if needed.

-

Lightly oil the lip before pressing in.

-

Use the correct driver to prevent distortion.

Symptoms of seal wear:

-

Oil weeping from the flywheel housing vent.

-

Drips forming at the damper area.

-

Residual oil on the flywheel after extended idle.

Oversize seal sleeves restore proper sealing diameter on worn crank surfaces.

-

Fitment: Front or rear of the 12V92 Turbo, depending on wear location.

-

Tip: Install with uniform pressure; never hammer the sleeve directly.

Gaskets for Cylinder Liners and Block Interfaces – Detroit Diesel 12V92 Turbo

Liner seals prevent coolant from leaking around the lower end of each cylinder liner.

-

Role in the 12V92 Turbo: Maintain isolation between coolant passages and the crankcase.

-

Replacement interval: Each time a liner is removed.

-

Failure symptoms: Milky oil, unexplained coolant loss, or crankcase pressurization.

Front End Plate Gasket

Located between the front end plate and the block, this gasket seals the gear drive housing.

-

Leak indicators: Oil film near accessory drive cover or timing components.

-

Installation tip: Clean surfaces and ensure correct gasket alignment before tightening bolts.

Gaskets for Lubrication System – Detroit Diesel 12V92 Turbo

The oil pan gasket seals the joint between the block and oil sump.

-

Construction: Composite or cork-based material designed for vibration absorption.

-

When to replace: Whenever the oil pan is removed for inspection or cleaning.

-

Torque pattern: Always tighten in a crisscross pattern to prevent rail distortion.

Oil Pump and Pickup Tube Gaskets

These gaskets seal the oil pump inlet and pickup tube on the 12V92 Turbo.

-

Function: Prevent suction leaks that could reduce oil flow to bearings and turbo.

-

Replacement: Required any time the oil pump or pickup tube is removed.

Gaskets for Cooling System – Detroit Diesel 12V92 Turbo

Seals the water rail manifold to the block.

-

Purpose: Maintains coolant flow integrity across both cylinder banks.

-

Leak signs: Coolant streaks along the manifold base or bubbling at seams during warm-up.

The thermostat gasket prevents coolant bypass at the thermostat housing.

-

Importance: Ensures proper warm-up and stable temperature regulation under turbo load.

Intercooler end plate and internal gaskets seal the water-to-air charge cooler assembly.

-

Configuration: Each intercooler typically requires multiple gaskets (often two end plate gaskets and four inner seals).

-

Failure signs: Oil mist or coolant droplets near the intercooler body.

-

Best practice: Pressure test the intercooler after resealing before reinstalling it.

Gaskets for Exhaust and Marine Manifold System – Detroit Diesel 12V92 Turbo

Marine Exhaust Manifold Gaskets

Marine manifold gaskets seal the water-jacketed exhaust manifolds on the 12V92 Turbo.

-

Material: Stainless-steel reinforced composite to withstand turbo temperatures and marine corrosion.

-

Inspection note: Clean all mating surfaces to bare metal and inspect for pitting before reassembly.

Marine Manifold Flange Spacer Gasket

This gasket fits between the exhaust flange and spacer, maintaining tight sealing on water-cooled exhaust sections.

-

Outside diameter: 6.25”

-

Inside diameter: 3.50”

-

Tip: Replace whenever the flange is separated, as heat cycling causes compression set.

Marine Exhaust Manifold JT 92 Gasket

A specialized marine manifold gasket for the 12V92 Turbo JT configuration.

-

Outside diameter: 6.50”

-

Inside diameter: 4.28”

-

Purpose: Maintains exhaust gas containment and coolant isolation at the junction between manifold and riser housing.

Gaskets for Flywheel Housing and Transmission Interface – Detroit Diesel 12V92 Turbo

This gasket seals the junction between the engine rear end plate and the flywheel housing.

-

Function: Prevents oil leakage from the crankcase rear face.

-

Replacement cue: Any time the flywheel housing is removed or when oil residue appears at the housing seam.

Flywheel Housing Cover Gasket

Used under the large inspection cover on the flywheel housing.

-

Purpose: Provides an oil-tight seal while allowing periodic access for inspection.

Allison Marine Transmission Gaskets (SAE #1 and SAE #2)

For marine applications of the 12V92 Turbo, gaskets between the flywheel housing and Allison M or MH transmissions ensure alignment and sealing.

-

SAE #1 gasket: Used when both housings share SAE #1 bolt pattern.

-

SAE #2 gasket: Most common fitment for 12V92 Turbo marine setups.

-

Tip: Confirm concentric alignment before torquing to prevent driveline vibration.

Gaskets for Governors and Accessories – Detroit Diesel 12V92 Turbo

Hydraulic Governor Gaskets

Two types: body-to-drive gasket and governor cover gasket.

-

Purpose: Contain oil inside the hydraulic governor assembly.

-

Leak symptoms: Oil weeping from governor seams or small puddles near the base.

-

Action: Replace both gaskets together for a full reseal.

Governor Spring Cover and Top Cover Gaskets

Seals the upper sections of the governor housing.

-

Function: Prevents dust and oil vapor escape.

-

Tip: Avoid over-tightening cover bolts; soft aluminum threads strip easily.

Starter mounting gasket prevents oil and debris from entering the bellhousing.

-

Use case: Replace during starter removal or electrical service.

-

Material: Oil-resistant fiber gasket for marine-grade protection.

Gaskets for Fuel and Pump Interfaces – Detroit Diesel 12V92 Turbo

Fuel and Water Pump Gaskets

Used to seal the pump bodies to the mounting surfaces.

-

Importance: Any leak here can allow air into the fuel system or coolant seepage into accessory drives.

-

Installation: Surfaces must be free of old gasket material; torque bolts evenly.

Raw Water Pump Mounting Gasket

Seals the saltwater pump base to its mounting flange.

-

Marine use: Prevents saltwater leaks that can corrode nearby components.

-

Best practice: Replace whenever the raw water pump is removed for impeller service.

Fresh Water Pump Cover Gasket

Prevents coolant leaks at the freshwater pump cover.

-

Tip: Always check the impeller cavity for corrosion before reassembly.

Gaskets for Sealants, Compounds, and Assembly Aids – Detroit Diesel 12V92 Turbo

Gasket Spray and Sealant Compounds

High-tack gasket spray helps hold gaskets in place during assembly and fills micro-surface imperfections.

3H Liquid Sealant provides a non-hardening seal for flexible joints.

Sensor-Safe Silicone RTVs (Ultra Blue and High Temp) are used for housing joints exposed to oil or moderate heat.

Non-Hardening Pliable Sealant remains flexible for parts requiring future disassembly.

Usage guidance for the 12V92 Turbo:

-

Do not over-apply sealant. Excess material can block oil or coolant passages.

-

Avoid acetic-cure silicone near sensors or copper components.

-

Apply only where Detroit Diesel specifies supplemental sealing.

Threadlocker Red – High Strength

Used for critical fasteners subject to vibration, such as turbo mount bolts or accessory brackets.

-

Removal note: Heat may be required for disassembly. Use only where permanent retention is desired.

Cold Weld Compound (J-B Weld)

A two-part epoxy useful for emergency, non-structural repairs on non-pressurized housings.

-

Not for: Exhaust or combustion sealing surfaces.

Gaskets for Block and Miscellaneous Components – Detroit Diesel 12V92 Turbo

Block Plug Gasket

A 2.5-inch diameter gasket used on threaded or plate-style block plugs.

-

Purpose: Seals coolant or inspection ports on the block exterior.

-

Tip: Clean plug threads and use anti-seize on reinstallation.

Includes gaskets for double oil coolers used on 12V92 Turbo configurations.

-

Function: Seals coolant-to-oil interfaces and prevents internal cross-leakage.

-

Replacement: Whenever oil coolers are cleaned or replaced.

Why Buy 12V92 Turbo Gaskets from Diesel Pro Power

Trusted Quality for the 12V92 Turbo

Each gasket, seal, and compound offered for the 12V92 Turbo meets or exceeds Detroit Diesel’s original specifications for temperature, pressure, and material compatibility.

Marine-Grade Reliability

The 12V92 Turbo is frequently found in marine propulsion and auxiliary power systems. Diesel Pro Power’s gaskets are designed to withstand salt exposure, vibration, and thermal cycling common to marine environments.

Fast Shipping and Expert Support

With over 40,000+ satisfied customers, Diesel Pro Power is the trusted source for Detroit Diesel gaskets worldwide. Every order ships quickly and is backed by customer service trained in 12V92 Turbo configurations.

One Source for Every Seal

From head gaskets and blower installation kits to marine exhaust manifold gaskets and turbo oil feed seals, all parts are available in one place for complete rebuilds or quick maintenance.

Summary of Key Gasket Groups – Detroit Diesel 12V92 Turbo

-

Overhaul Gasket Kit: Complete rebuild coverage

-

Cylinder Head Gaskets: Four required for full engine

-

Rocker Cover Gaskets: For aluminum covers

-

Blower & Air Inlet Gaskets: Blower kit, Striker plate, air inlet housing

-

Turbo Gaskets: Riser, oil feed, oil return, high-temp compound

-

Crankshaft Seals: Front/rear, standard or oversize, right/left rotation

-

Cooling System Gaskets: Water manifold, thermostat, intercooler plates

-

Exhaust Gaskets: Marine manifold, JT 92, flange spacer

-

Lubrication Gaskets: Oil pan, oil pump, pickup tube

-

Governor & Accessory Gaskets: Hydraulic governor, top/spring covers, starter

-

Fuel & Pump Gaskets: Water pump, raw water pump, fresh water pump cover

-

Sealants & Compounds: RTVs, liquid sealants, threadlockers, gasket sprays

-

Block & Miscellaneous: Block plug gasket, oil cooler kit

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588