16V149 Detroit Diesel Parts Turbo - Oil Cooler Section

Loading...

Loading... 16V149 Detroit Diesel Turbo Engine – Oil Cooler & Lubrication System Parts Catalog

The Detroit Diesel 16V149 Turbo engine represents one of the most powerful and enduring designs in the 149 series. Renowned for its performance in heavy-duty marine, industrial, and power generation applications, the 16V149 is a 16-cylinder, two-stroke engine designed for maximum reliability under sustained load. Its lubrication and oil cooling systems are critical to maintaining efficient operation and longevity.

This section covers the oil cooler assembly, oil pump, gaskets, filters, and related pressure control components for the 16V149 turbocharged configuration. Each component plays a vital role in ensuring proper lubrication, temperature regulation, and internal engine protection.

Understanding the Oil Cooling and Lubrication System

The lubrication system in a Detroit Diesel 16V149 Turbo engine is designed to:

-

Supply continuous, pressurized oil to all moving parts.

-

Cool internal components through thermal transfer.

-

Clean the engine by removing impurities and carbon deposits.

-

Maintain consistent oil pressure under varying operating conditions.

The oil cooler, oil pump, and filter system form the heart of this network. Together, they ensure that lubricating oil maintains optimal viscosity and temperature, reducing friction and preventing wear even in high-performance environments such as marine propulsion or heavy equipment.

Detroit Diesel Oil Pump – Rebuilt

Product Description:

The rebuilt Detroit Diesel Oil Pump for the 16V149 engine is precision-remanufactured to meet original factory specifications. Each unit is disassembled, cleaned, inspected, and reassembled using new seals, bearings, and shafts.

Key Features:

-

Provides consistent oil flow under both idle and full-load conditions.

-

Fully pressure-tested to ensure leak-free operation.

-

Includes a refundable core deposit when the old unit is returned.

-

Designed for Detroit Diesel 16V149 Turbo lubrication systems.

Function:

The oil pump draws oil from the sump and delivers it through galleries to bearings, pistons, camshafts, and turbocharger lubrication lines. Proper pressure is crucial to prevent metal-on-metal contact, and the rebuilt unit restores this essential performance to like-new standards.

Why Choose Diesel Pro Power:

Every pump offered by Diesel Pro Power undergoes a rigorous quality check to ensure long service life and reliability. Customers benefit from expert support, worldwide shipping, and a proven track record of excellence with over 40,000 satisfied customers globally.

Detroit Diesel Oil Cooler – 30 Plates

Product Description:

The 30-plate oil cooler is an integral component of the 16V149’s lubrication system, maintaining oil at a safe operating temperature by transferring excess heat to the coolant.

Construction Details:

-

Made with high-strength aluminum or copper alloy plates for efficient thermal exchange.

-

Corrosion-resistant materials for extended marine or industrial use.

-

Compact yet capable of handling high flow rates typical of V16 turbocharged systems.

Performance Benefits:

-

Stabilizes oil temperature to prevent viscosity breakdown.

-

Reduces thermal stress on bearings and moving parts.

-

Ensures sustained performance during continuous operation.

Applications:

This oil cooler is suitable for 16V149 turbocharged engines in propulsion systems, standby generators, and offshore equipment.

Maintenance Tip:

Inspect the oil cooler regularly for signs of oil contamination or coolant leaks. A clogged or corroded cooler can cause oil overheating, leading to premature engine wear.

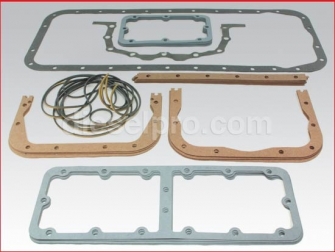

Detroit Diesel Oil Cooler Gasket Kit for 8V149, 12V149 & 16V149 Engines

Product Description:

The Oil Cooler Gasket Kit includes all necessary gaskets and seals required when installing or servicing the oil cooler on any 149-series engine, including the 8V, 12V, and 16V variants.

Contents Include:

-

Oil cooler end gaskets.

-

Sealing rings for coolant and oil passage interfaces.

-

Mounting gaskets for oil filter housings.

Compatibility:

This kit ensures a proper seal for Detroit Diesel 16V149 Turbo oil coolers, preventing leaks and cross-contamination between oil and coolant systems.

Installation Tip:

Always clean mating surfaces thoroughly and apply torque to manufacturer specifications. Even minor gasket damage can result in reduced oil pressure or coolant leakage.

Why Use OEM-Quality Gaskets:

Detroit Diesel’s oil systems operate under high temperature and pressure. Using precision-fit gaskets ensures durability, maintains system pressure, and prevents costly downtime.

Detroit Diesel Gasket Kit for Oil Pan – 16V149 Engines

Product Description:

The oil pan gasket kit provides all components necessary for resealing the sump to the block during overhaul or maintenance.

Features:

-

Made from high-temperature resistant materials.

-

Engineered to withstand oil exposure and vibration.

-

Prevents oil seepage and maintains crankcase integrity.

Importance:

A properly sealed oil pan prevents leaks that can lead to oil starvation and contamination of bilge or deck surfaces in marine applications. Regular inspection and replacement during rebuilds are recommended for long-term reliability.

Oil Filter – Spin-On Type

Product Description:

This spin-on oil filter fits Detroit Diesel and Cummins engines, including the 16V149. It replaces traditional cartridge-style filters for easier maintenance and improved sealing.

Key Features:

-

High-capacity pleated media for superior filtration efficiency.

-

Designed for heavy-duty marine and industrial applications.

-

Threaded base allows quick replacement without tools.

Function:

The oil filter captures soot, debris, and metal contaminants before they reach bearings and turbo components. Maintaining clean oil extends the life of the engine and improves performance.

Maintenance Interval:

Change filters at recommended intervals or more frequently in severe service conditions such as continuous operation or high load.

Fuel & Oil Pressure Switches – 5, 10, 20, and 27 PSI Make/Break

Overview:

Pressure switches serve as vital monitoring devices in the lubrication system, ensuring oil pressure remains within safe operating limits. Each switch activates or deactivates circuits based on the set PSI threshold.

5 PSI Make/Break Pressure Switch

Ideal for low-pressure alarms or backup safety circuits. Provides early warning for lubrication issues.

10 PSI Make/Break Pressure Switch

Commonly used for monitoring idle oil pressure levels in large Detroit Diesel engines.

20 PSI Make/Break Pressure Switch

Used in engines operating under higher baseline oil pressures. Helps protect turbo bearings and camshaft assemblies.

27 PSI Make/Break Pressure Switch

High-threshold version suitable for heavy-duty marine propulsion engines, ensuring early response to oil pressure drops.

Technical Note:

Each switch features a 1/8” NPT thread for compatibility and quick installation into existing ports. Diesel Pro Power offers precise replacements built to match OEM pressure calibration and electrical characteristics.

Mechanical & Electric Gauges

Product Overview:

Diesel Pro Power provides a range of mechanical and electrical oil pressure gauges suitable for 12V and 24V systems. These gauges work with the pressure switches listed above, offering real-time feedback on oil system health.

Gauge Options:

-

Mechanical Standard Gauges: Direct oil line connection for accurate readings.

-

Mechanical Gauges with Alarm: Include an integrated alarm circuit for low-pressure warning.

-

Electrical Gauges (12V & 24V): For remote mounting and electronic monitoring systems.

Installation and Use:

Regularly monitor oil pressure readings to prevent catastrophic engine failures. Abnormal readings often indicate clogged filters, failing pumps, or coolant contamination.

Maintaining the Oil Cooling System of the 16V149 Detroit Diesel

A well-maintained oil cooling and lubrication system ensures the 16V149 Turbo operates within its designed thermal and mechanical limits. The following practices can help extend service life:

-

Regular Oil Changes: Use manufacturer-recommended lubricants and replace filters at scheduled intervals.

-

Cooler Cleaning: Flush and inspect the oil cooler during every major service to prevent clogging.

-

Monitor Gauges: Keep an eye on oil temperature and pressure levels during operation.

-

Replace Worn Gaskets: Any sign of seepage around oil cooler or oil pan joints should prompt immediate replacement.

Why Buy Oil Cooler Parts for Your 16V149 Detroit Diesel Turbo from Diesel Pro Power

Diesel Pro Power has become a trusted global supplier for Detroit Diesel 149 Series engine parts, combining technical expertise, fast delivery, and exceptional service.

Key Advantages:

-

Over 40,000 satisfied customers worldwide.

-

All components meet or exceed OEM specifications.

-

Ready-to-ship inventory with real-time availability.

-

Expert assistance to ensure you get the exact part for your 16V149 Turbo.

-

Secure packaging and reliable international shipping.

Commitment to Quality:

Every oil pump, cooler, and gasket kit is inspected before shipment. Diesel Pro Power’s reputation is built on precision and dependability—essential qualities when maintaining high-performance marine or industrial engines.

Customer Support:

Whether you are overhauling a full 16V149 turbo engine or replacing an individual oil cooler, Diesel Pro Power’s experienced staff can guide you through product selection, installation best practices, and maintenance scheduling.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588