Parts for Detroit Diesel 16V71 Non-Turbo - Oil Pump Section

Loading...

Loading... -

-

-

-

-

-

Detroit Diesel Oil Pan Gasket for 371,16V92,16V71

5150115

For 3-71 and front lower oil pan gasket for 16V71 (2 per engine) & 16V92 (2 per engine)Price: $ 32.02 -

Detroit Diesel Oil Pan Gasket for 471,16V71,16V92

5150116

For 4-71 and rear lower oil pan gasket for 16V71 (2 per engine), 16V92 (2 per engine)

Price: $ 27.07 -

-

-

-

Detroit Diesel Gasket, Oil Pressure Regulator Add Relief for V71, V92 Series

5117269

.Price: $ 3.82 -

-

-

-

-

Detroit Diesel Oil Filter Adaptor for Engine & Allison transmission

25010854

From cartridge to spin-on

Price: $ 208.96 -

-

-

-

Oil Filter Removal Wrench for Detroit Diesel, Caterpillar & Cummins

2321

4-21/32" to 5-5/32"Price: $ 63.29 -

-

-

-

Oil cooler installation kit for Detroit Diesel

2COOLERS-INS-K

For Double oil coolersPrice: $ 242.09 -

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

Detroit Diesel Water Manifold to Oil Cooler Housing Seal

5159457

2 1/2" outside diameter, with inner lipPrice: $ 5.48 -

Detroit Diesel Seal, Water Manifold to Oil Cooler Housing

5156770

2 3/4" outside diameter, with inner lipPrice: $ 5.46 -

Detroit Diesel Seal for Oil Cooler Housing Water Inlet, Series V71 and 92

23501837

2 3/4" Inside diameterPrice: $ 6.39 -

-

-

Fuel & Oil Pressure Switch - 10 PSI Make/Break

23520024

10 PSI make/break with 1/8 nptPrice: $ 99.79 -

Fuel & Oil Pressure Switch - 20 PSI Make/Break

23520025

20 PSI make, break with 1/8 nptPrice: $ 96.44 -

Fuel & Oil Pressure Switch - 27 PSI Make/Break

23511819

27 PSI make/break with 1/8 nptPrice: $ 81.10 -

-

Parts for Detroit Diesel 16V71 Non-Turbo – Oil Pump Section

The Detroit Diesel 16V71 Non-Turbo engine stands as one of the most respected powerplants in heavy-duty marine, industrial, and generator applications. Belonging to the legendary Series 71 two-stroke line, the 16V71 engine is known for its durability, high torque output, and mechanical simplicity. The oil system—particularly the oil pump and associated components—is essential to ensuring this massive 16-cylinder engine maintains proper lubrication and temperature balance during demanding operation.

This catalog section provides a comprehensive overview of oil pumps, gaskets, valves, seals, shims, dipsticks, and pressure components designed for the Detroit Diesel 16V71 Non-Turbo engine. Each part listed is manufactured to exact Detroit Diesel specifications to guarantee performance, reliability, and longevity in both standard and high-demand conditions.

Understanding the Detroit Diesel 16V71 Oil System

The oil system on the Detroit Diesel 16V71 Non-Turbo is a full-pressure, wet-sump lubrication system engineered to distribute oil evenly through bearings, camshafts, rocker arms, and cylinder liners. The heart of this system is the engine oil pump, which circulates oil from the sump through filters, coolers, and galleries to ensure constant lubrication.

Maintaining this system requires high-quality components. From precision-cut gaskets that prevent leaks to shims that calibrate oil pump clearances, every part plays a critical role in sustaining oil pressure, cooling, and contamination control.

Oil Pump Shims for Detroit Diesel 16V71

Oil pump shims are thin spacers used to precisely set oil pump end clearances. Proper clearance is vital for maintaining consistent oil pressure and preventing premature wear in gears and bearings.

Available shim sizes:

-

0.05 mm (0.002") – for fine adjustment and minor tolerance corrections

-

0.10 mm (0.004") – ideal for restoring correct pressure after component rebuilds

-

0.20 mm (0.008") – for more significant spacing requirements or when resurfaced parts reduce internal clearance

Each Detroit Diesel Oil Pump Shim for Series 71 is made from durable steel and precision stamped to OEM standards. These shims help extend oil pump life, maintain pressure stability, and prevent cavitation that can lead to bearing damage.

Oil Pressure Regulation and Control

Oil pressure regulation in the 16V71 engine depends on two critical valves—the oil regulator valve and the oil relief valve. These components manage oil flow to prevent both excessive pressure (which can damage seals) and low pressure (which can cause bearing failure).

-

Designed to maintain optimal pressure across varying RPM and load conditions

-

Available for multiple configurations, including compatibility with the 12V71, 16V71, and 16V92 engines

-

Built from heat-treated steel to withstand continuous cycling and thermal expansion

-

Provide a secondary path for excess oil flow during high-pressure events

-

Commonly shared across Series 71 and Series 92 engines

-

Precision-calibrated spring tension ensures accurate relief pressure levels

Both valves are fully interchangeable within their engine families when configured for the correct housing, making them essential spares for fleet and maintenance operations.

Oil Pan Gaskets and Seals

Oil pan gaskets form the seal between the engine block and the oil pan, keeping oil inside the crankcase and preventing leakage around bolts and seams. For the Detroit Diesel 16V71, there are multiple gasket variations due to its two-piece oil pan design—a front and rear lower pan section.

Front and Rear Lower Oil Pan Gaskets:

-

Each 16V71 engine uses two gaskets per section (four total per engine)

-

Gaskets are made from composite materials that resist oil degradation and thermal cycling

-

Precision cut for exact fit and easy installation

Main Oil Pan to Block Gasket:

-

Provides full sealing coverage between the upper crankcase and oil pan flange

-

Compatible with both the 12V71 and 16V71 non-turbo models

Proper gasket maintenance prevents air leaks that can cause aeration of the oil, maintaining consistent oil pressure throughout the lubrication circuit.

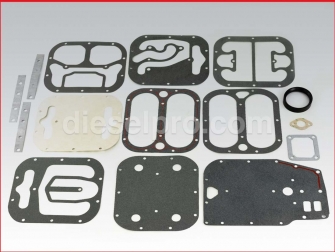

Oil Pump and Cooler Gaskets

The oil pump gaskets and inlet gaskets are small but essential sealing components that prevent oil bypass at connection points. The oil pump inlet gasket ensures the suction side of the pump remains airtight, avoiding pressure loss that can starve bearings.

Complementing these are the oil cooler gaskets, which maintain tight seals between cooler plates, covers, and housings. The 16V71’s cooling system relies on these gaskets to maintain proper temperature regulation and oil integrity.

Typical gaskets include:

Each gasket is made from reinforced materials capable of withstanding high temperature and oil exposure, ensuring leak-free operation under extreme conditions.

Oil Filters and Adaptors

The Detroit Diesel 16V71 Non-Turbo engine supports both cartridge-type and spin-on oil filters, depending on the generation and application of the engine.

-

Traditional design for early Series 71 engines

-

Require a filter base housing that allows replacement of the internal element

-

Modernized replacement style for quicker maintenance

-

Feature integrated housing for easy removal and installation

-

The oil filter base holds the cartridge element in place and routes oil through filtration channels

-

The filter adaptor allows the engine to be converted from the older cartridge type to the newer spin-onconfiguration, reducing maintenance time

These components maintain oil cleanliness by filtering out carbon, sludge, and metal particles that accumulate during normal operation. Proper filter selection ensures the longevity of pistons, bearings, and crankshafts.

Oil Cooler Assemblies

The oil cooler regulates oil temperature by transferring heat from the circulating oil into the engine’s cooling water. Maintaining the correct oil temperature ensures viscosity remains stable and prevents breakdown under load.

Available variants include:

-

24-Plate Oil Cooler with Nipples (for specific plumbing configurations)

-

32-Plate Oil Cooler (for high-demand or continuous-duty marine engines)

Oil Cooler Installation Kits are also available for engines configured with double oil coolers, often used in high-horsepower or tropical climate operations. These kits include the necessary gaskets, seals, and fittings to ensure a leak-free installation.

Seals and Water Connections

A number of seals are essential for keeping the oil and water systems isolated from one another, particularly in the oil cooler housing. These seals prevent coolant intrusion into the oil system—a potentially catastrophic failure mode.

Key Seals Include:

-

Water manifold to oil cooler housing seal (2 ½" and 2 ¾" OD options)

-

Oil cooler housing water inlet seal (shared across Series 71 and 92 engines)

-

Oil cooler water inlet gaskets for proper sealing at flange junctions

All seals are manufactured with oil-resistant rubber compounds and reinforced lips to maintain a secure fit during temperature fluctuations.

Dipsticks, Tubes, and Guides

Monitoring oil levels accurately is essential for the health of a 16-cylinder engine like the 16V71. The dipstick assemblyprovides this vital check.

Dipstick Options:

-

44.25” Long Dipstick – standard for marine and stationary engines

-

27.25” Dipstick – used in compact or industrial configurations

-

Dipstick Tube and Guide – ensure smooth insertion and protect the stick from damage

Each assembly is crafted for precise oil level reading, ensuring correct lubrication without overfilling, which can cause foaming or pressure surges.

Oil Pressure and Temperature Monitoring

Oil pressure switches are crucial in detecting changes in lubrication performance. The Detroit Diesel 16V71 Non-Turboengine uses a variety of make/break switches calibrated to specific pressure points:

-

5 PSI – for low-pressure warning systems

-

10 PSI – common on generator and industrial sets

-

20 PSI – used in marine propulsion applications

-

27 PSI – high-performance setting for constant monitoring

Each switch uses a 1/8” NPT thread and integrates with mechanical or electrical gauges for accurate dashboard readings. Diesel Pro Power also provides mechanical and electric gauges (12V and 24V) compatible with these switches, ensuring comprehensive monitoring of the engine’s lubrication performance.

Oil Filter Service Tools and Accessories

To simplify maintenance, Diesel Pro Power offers specialized tools such as the oil filter removal wrench. Designed for filters between 4-21/32” and 5-5/32”, this adjustable wrench provides secure grip and leverage during filter replacement.

Other accessories, such as copper washers and oil filter adaptor gaskets, complete the assembly, ensuring tight, leak-free installations and secure fittings.

Why Choose Diesel Pro Power for Detroit Diesel 16V71 Oil System Components

Diesel Pro Power has earned the trust of over 40,000 satisfied customers worldwide by offering a superior experience in marine and industrial diesel engine parts. For the Detroit Diesel 16V71 Non-Turbo engine, Diesel Pro Power provides every critical oil system component under one roof—each item verified for compatibility, quality, and long-term durability.

Benefits of choosing Diesel Pro Power:

-

Expert-verified parts compatible with the 16V71 Non-Turbo engine

-

New and rebuilt components tested for performance and reliability

-

Comprehensive selection of gaskets, valves, and shims for the entire oil system

-

Fast global shipping from a secure U.S. warehouse

-

Bilingual customer support and technical assistance

-

Easy online ordering with real-time inventory visibility

Whether you’re performing a full engine rebuild, preventive maintenance, or troubleshooting oil pressure issues, Diesel Pro Power offers reliable parts, clear product descriptions, and trusted expertise that help keep your Detroit Diesel 16V71 running strong.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588