Parts For Detroit Diesel 16V92 Turbo - Gasket Section

Loading...

Loading... -

-

-

-

-

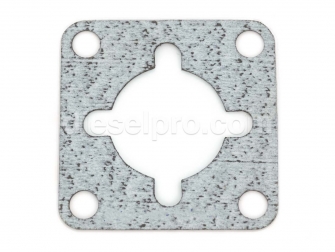

Detroit Diesel Inspection Cover Gasket for Series V71, V92 and for 6V53, 8V53 new style

8923792

.

Price: $ 8.61 -

Detroit Diesel Rear Crankshaft seal

5114335

Rear for 271, 371, 471, 671,6V71, 8V71, 12V71, 8V53 and Front for 16V71, 12V92, 16V92. - Standard - Single Lip

Price: $ 33.18 -

Detroit Diesel Rear Crankshaft seal.

5197860

Rear - Oversize - Single Lip for 271, 371, 471, 671, 6V71, 8V71, 8V53 and Front for 16V71,12V92, 16V92 Engines

Price: $ 45.45 -

Detroit Diesel Crankshaft seal for 16V71, 6V92, 8V92, 12V92 , 16V92

8929750

Rear - Standard - Single Lip - Universal rotation (right or left)

Price: $ 214.19 -

Detroit Diesel crankshaft seal for 6V92, 8V92, 12V92 and 16V92 engines

5135150

Rear - Standard - Double lip

Price: $ 108.81 -

Detroit Diesel crankshaft seal for 6V92, 8V92, 12V92 and 16V92 engines

5198159

Rear - Oversize - Double lip - Universal rotation

Price: $ 192.85 -

Detroit Diesel crankshaft Seal for 6V92, 8V92, 12V92 and 16V92 engines

23501544

Rear - Oversize - Single lip - Right hand rotation

Price: $ 53.34 -

Detroit Diesel Crankshaft seal, for 16V71, 6V92, 8V92, 12V92 , 16V92 engines

23501545

Rear - Oversize - Single lip - Left hand rotation

Price: $ 95.22 -

Detroit Diesel Sleeve crankshaft seal for 16V71, 6V92, 8V92, 12V92 , 16V92 engine

23507226

Rear - Oversized

Price: $ 27.93 -

Detroit Diesel Head gasket kit for 8V92 and 16V92

5199674

8V92 engine requires 2 kits

16V92 engine requires 4 kits

Price: $ 89.69 -

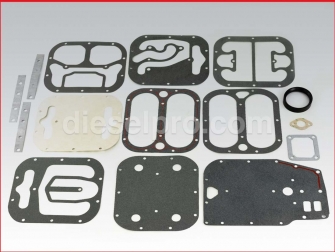

Detroit Diesel Rocker cover kit, for 4-71, 8V71, 16V71, 8V92, 16V92

5149511

For use with aluminum rocker covers. New stylePrice: $ 68.65 -

-

Detroit Diesel Rocker cover gasket , gray

5104081

For use with aluminum rocker covers. New stylePrice: $ 22.35 -

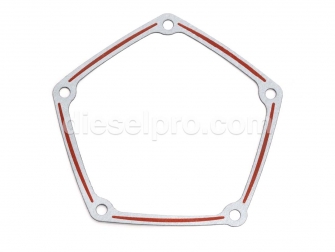

Detroit Diesel Flywheel Housing Gasket for V71 and V92

5144875

Gasket located between end plate and flywheel housingPrice: $ 30.84 -

-

-

Allison Flywheel Gasket for Marine Transmission M and MH - SAE 2 (Most Common)

29503155

Use when engine housing size is the same as transmission

Price: $ 102.60 -

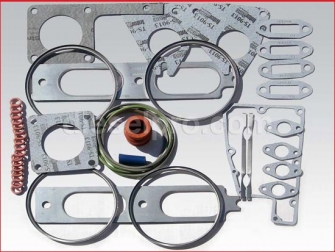

Detroit Diesel Blower installation gasket kit for turbo engines 8V71, 16V71, 8V92 and 16V92

5149643

This kit covers one blowerPrice: $ 98.27 -

-

-

Detroit Diesel Head to Manifold Gasket for 471, 671, 8V71, 12V71, 16V71, 8V92, 16V92

5120224

Click on + Pictures below to see how many are needed per engine

Price: $ 13.74 -

Detroit Diesel Turbo riser gasket

8923492

Inner width 2”, Inner Length 3.75”, Outer width 3.75”, Outer Length 5.5”Price: $ 9.08 -

762 Hi-Temperature jointing compound for Detroit Diesel and Cummins turbos

762

225 gm tube - Temp range 550C to 760CPrice: $ 188.19 -

-

-

Detroit Diesel Gasket for marine manifold 12V71, 6V92, 8V92, 12V92, 16V92

23515227

Outside diameter 6.80", inside diameter 4.25"Price: $ 79.86 -

-

Detroit Diesel Oil Pan Gasket for 371,16V92,16V71

5150115

For 3-71 and front lower oil pan gasket for 16V71 (2 per engine) & 16V92 (2 per engine)Price: $ 32.02 -

Detroit Diesel Oil Pan Gasket for 471,16V71,16V92

5150116

For 4-71 and rear lower oil pan gasket for 16V71 (2 per engine), 16V92 (2 per engine)

Price: $ 27.07 -

-

-

-

Detroit Diesel Gasket for Hydraulic Governor

23509675

Gasket between Governor and DrivePrice: $ 5.50 -

Oil cooler installation kit for Detroit Diesel

2COOLERS-INS-K

For Double oil coolersPrice: $ 242.09 -

-

-

-

-

-

-

-

Detroit Diesel Gasket, marine manifold flange spacer

5101914

Outside diameter 6.25", inside diameter 3.50"Price: $ 69.50 -

Detroit Diesel Marine exhaust manifold gasket for engine JT 92

23516686

Outside diameter 6.50", inside diameter 4.28"Price: $ 69.78 -

-

Green Paint for Detroit Diesel Engines

26006

Available for ground shipping only in USA and CanadaPrice: $ 12.46 -

-

Gasket Spray -High Tack Sealant (Hold & Seals Cut Gaskets)

99MA

For Detroit Diesel & Cummins engines. Available for ground shipping only in USA and CanadaPrice: $ 20.55 -

3H Gasket Maker

3H

For Detroit Diesel & Cummins engines. Available for ground shipping only in USA and CanadaPrice: $ 17.46 -

-

-

-

-

Gasket Maker - Ultra Blue RTV Silicone Sensor Safe

77BR

For Detroit Diesel & Cummins enginesPrice: $ 11.03 -

-

Parts for Detroit Diesel 16V92 Turbo – Gasket Section

The Detroit Diesel 16V92 Turbo is a high-output, two-stroke V-16 that thrives on precision sealing. Every interface—oil, coolant, air, and exhaust—depends on the right gasket or seal installed on properly prepared surfaces. This page focuses exclusively on gaskets, seals, and related installation materials as they apply to the 16V92 Turbo. Even if some catalog labels elsewhere might mention broader fitments, the guidance below is written only for 16V92 Turbo applications so you can plan and execute your job without second-guessing.

What follows is a practical, field-tested walkthrough of each item listed on this section—where it lives on the 16V92 Turbo, what it does, why it fails, how to install it correctly, and what to double-check before you button everything up. You’ll also find quantity pointers, torque/sequence reminders, troubleshooting cues, and best-practice notes for a long-lasting, leak-free result.

Block Plug Gasket (2.5" Diameter)

The block plug gasket keeps coolant contained at the block’s service openings. On a 16V92 Turbo, coolant integrity is foundational to engine health and turbocharger longevity. Any seep at the block plug can introduce air into the cooling circuit, promote internal corrosion, and leave chalky residue that masks other issues.

Best practices for the 16V92 Turbo

-

Clean and lightly dress the plug seat on the block; remove deposits without scratching the sealing land.

-

Replace this gasket any time the plug is disturbed during draining, flushing, or pressure testing.

-

After installation, pressure-test the cooling system cold and then again after a heat-soak run.

Overhaul Gasket Kit (Complete Engine Reseal)

A quality overhaul gasket kit consolidates the full array of gaskets and seals needed to reseal the 16V92 Turbo from top to bottom. Using a matched kit ensures consistent materials and crush characteristics across the entire engine, reducing the chance of mixing incompatible papers, elastomers, or composites.

When to use

-

Full engine rebuilds or deep services (liners, heads, bearings).

-

Major leak remediation where multiple systems (oil, coolant, exhaust) need resealing.

-

Preventive refit schedules where you want everything standardized in one go.

Installation pointers

-

Stage and label sub-kits (upper engine, lower engine, cooling, exhaust, ancillary covers) before starting.

-

Verify surface prep standards: clean, flat, smooth, lint-free.

-

Follow torque sequences meticulously, in multiple steps, with accurate torque tools.

Cylinder Liner Seals

On a two-stroke 16V92 Turbo, liner seals separate coolant from the crankcase. Any compromise here risks coolant-in-oil contamination, bearing damage, and accelerated wear everywhere from pistons to turbocharger bearings (via oil coking).

Fitment & setup notes

-

Inspect counterbores for scale or micro-pitting. Correct as needed; a flawed landing will cut a new seal.

-

Confirm liner protrusion with the correct tools; out-of-range protrusion compromises head gasket life.

-

Lubricate seals per spec and use proper liner guides to avoid twisting/rolling the seals during insertion.

Inspection Cover Gaskets

The 16V92 Turbo uses block inspection covers to access internals and passages. Their gaskets are “small but mighty”: reusing flattened covers is a common source of chronic weeping that dusts the block with oil film.

Pro move

-

Replace any time a cover is off.

-

Clean both cover and block faces; look for warping and correct if needed.

-

Tighten evenly to avoid corner lift.

Cylinder Head Gasket Kits (Quantity Guidance & Technique)

A 16V92 Turbo requires four head gasket kits (two per bank). Correct head clamping is critical given boosted cylinder pressures and the two-stroke scavenge dynamics.

Essentials for success

-

Verify deck flatness and surface finish; carbon flecks or lint will compromise fire ring compression.

-

Clean fasteners and holes; oil or debris in threads skews clamp load.

-

Follow the exact tightening sequence in multiple stages; re-check if the manual calls for it after heat-soak.

-

Keep gasket surfaces pristine—handle by the edges and store flat until use.

Rocker Cover Gaskets & Kits (Aluminum Cover Style)

New-style gray rubber rocker cover gaskets and matched kits are designed for aluminum covers on the 16V92 Turbo. They resist creep and cold-flow, preventing the oil mist that can otherwise collect on breather plumbing and intake paths.

Installation checklist

-

Degrease both the cover and head rail.

-

Confirm the gasket sits without twist; corners should lay flat.

-

Torque evenly; over-tightening deforms aluminum flanges and invites leaks.

Crankshaft Seals (Front/Rear, Standard/Oversize, Single/Double Lip)

The 16V92 Turbo’s sustained loads and case ventilation flow place real demands on the crank seals. You’ll encounter standard and oversize diameters, as well as single-lip (low friction) and double-lip (enhanced exclusion) designs. If the crank journal shows a wear groove, pair an oversize seal with the correct wear sleeve to restore the sealing surface.

Front vs. rear on the 16V92 Turbo

-

Front: Prevents oil from escaping at the accessory drive end.

-

Rear: Lives behind the flywheel housing; a leak here is often mistaken for other housing or transmission interface gaskets.

Fitment technique

-

Lightly polish the journal; remove burrs at keyways.

-

Pre-lube the lip and use an installation guide to avoid damage over splines or sharp edges.

-

If a groove is present, do not rely on a standard seal; use the oversize plus sleeve combination.

Rotation-Specific Rear Seals (Right-Hand, Left-Hand, Universal)

Some rear seals for the 16V92 Turbo are rotation-specific. Installing a right-hand lip on a left-hand rotating engine (or vice-versa) can “pump” oil the wrong direction and cause immediate leakage. Where correct rotation is unknown, universal-rotation designs are a safe choice; otherwise, match the seal to the engine’s actual rotation.

Verification tip

-

Confirm rotation from build records or observe crank rotation at the flywheel with proper safety procedures before ordering/installing.

Turbocharger Interface Gaskets (Riser, Oil Supply, Oil Return)

Riser gasket

Maintains exhaust gas integrity into/through the riser. A poor seal here mimics turbo lag, elevates EGTs, and leaves sooting patterns.

Oil supply gasket

Secures clean pressurized oil to the turbo bearing housing. Replace on any turbo service or oil line disturbance.

Oil return gasket

Proper sealing allows unrestricted gravity return to the crankcase. A misaligned or pinched return gasket can cause oil to back up into the turbo, showing up as oil in the compressor housing.

Installation notes

-

Dry-fit and inspect flange faces; remove warpage and scale.

-

Tighten in sequence from center out.

-

Where specified, a thin film of high-temp jointing compound can be helpful—use sparingly and only as directed.

Marine Exhaust Manifold Gaskets (Flange, Spacer, JT-92 Style)

The 16V92 Turbo’s marine exhaust manifolds operate in a harsh hot-gas/cold-water neighborhood. Gaskets must handle thermal shock and maintain clamp load over time.

Flange & spacer gaskets

-

Choose gasket OD/ID profiles that match the manifold and riser exactly; no gasket edge should protrude into gas flow.

-

Spacer gaskets are used where riser height/geometry demands a shim while keeping flow smooth.

JT-92 style

-

Many 16V92 Turbo marine conversions use JT-92 manifold geometries; use the corresponding gasket profile for a perfect fit.

Pro tip

-

Align dry, then torque gradually in cross-pattern stages. Re-torque after initial heat cycle if specified.

Water Rail & Cooling Gaskets (Water Manifold, Fresh Water Pump Cover)

Water manifold (rail) gasket

Seals the coolant distribution rail to the heads. Because the 16V92 Turbo cycles between load and idle in marine service, the rail sees constant thermal expansion. Pitted or scaled surfaces undermine even the best gasket.

Fresh water pump cover gasket

A small seal preventing seep at the pump face. Replace whenever the cover is disturbed; confirm cover flatness and impeller clearance during reassembly.

Block water outlet gasket (block heater port)

Seals the block outlet and, where fitted, the heater element interface. If the heater has seized over time, plan on a new gasket during removal.

Raw Water Pump Mounting & Plate Gaskets

Raw water carries sediment and marine life; gaskets at the mounting and plate interfaces can erode if the pump faces aren’t flat or the shaft bearings are loose.

Checklist

-

Inspect for shaft play; correct any wobble before installing new gaskets.

-

Verify faces are true; lap lightly if needed.

-

Use new hardware where corrosion has affected clamp force.

Oil Pan Gaskets (Main, Front Lower, Rear Lower)

Many 16V92 Turbo marine configurations use sectional lower pans. Expect two front and two rear lower pan gaskets per engine, depending on exact pan design. Warped rails from over-torque are a frequent cause of recurring leaks.

Installation best practices

-

Straighten pan rails with a flat bar and careful hammer/dolly work.

-

Degrease and dry thoroughly; avoid RTV globs at corners—use only where specified.

-

Torque in stages and pattern; let the gasket seat, then re-check.

Oil Pump Inlet & Oil Pick-Up Tube Gaskets

These gaskets are critical to preventing aeration at the pump inlet. Aerated oil will show up as intermittent low pressure at hot idle and erratic gauge behavior.

Do this while the pan is down

-

Replace the pick-up tube gasket and confirm the tube is tight and correctly positioned.

-

Clean the strainer and inspect for cracks.

-

Replace the oil pump inlet gasket, ensuring perfect alignment.

Governor & Accessory Cover Gaskets

Stable governor operation is essential to smooth fueling and turbo response on the 16V92 Turbo. Replace cover gaskets whenever the governor housing is opened and keep sealant away from calibrated orifices.

Steps

-

Clean mating faces; no scratches or rolled edges.

-

Apply only the specified sealant, and only where called for.

-

Tighten methodically; uneven clamp leads to edge weeping.

Flywheel Housing Gaskets (Housing Cover & Housing-to-Bell Interfaces)

The flywheel housing area must remain clean and oil-tight to protect the coupling, damper, and any driven accessories. Replace the large cover gasket when servicing rear-end components, and use the correct housing interface gasket when remating the bell.

Leak-trace tip

-

A rear housing seep can masquerade as a rear main seal leak. Clean, run, dye-check if necessary, and pinpoint before rework.

Interface Gaskets to Marine Gear (Allison M/MH – SAE #1 / #2)

Many 16V92 Turbo marine installations couple to Allison M or MH gears. The housing-to-gear interface must match SAE #1 or SAE #2 as built. The correct gasket preserves face parallelism and helps maintain overall alignment under clamp load.

Alignment matters

-

Confirm housing size before ordering.

-

Inspect and clean dowel holes; dowel engagement ensures true alignment.

-

Torque evenly in a star pattern to avoid skew.

Oil Cooler Installation Kit (Double Cooler Configuration)

Where the 16V92 Turbo is fitted with dual oil coolers, the dedicated installation kit provides the correct seals and gaskets for clean assembly. Oil-to-water interfaces must remain tight; a mis-seated gasket here can cross-contaminate or starve the lubrication circuit.

Assembly tip

-

Lubricate o-rings and ensure they do not pinch.

-

Confirm cooler cores are pressure-tested and clean before installation.

Fuel & Water Pump Gaskets (Ancillary)

A simple pump gasket can be the difference between a clean engine and a mess that obscures other issues. Replace whenever a pump is disturbed; torque to spec and recheck after a heat cycle.

Starter Flange Gasket

This gasket keeps oil from misting at the starter flange and reduces salt-air intrusion into the bellhousing area. It’s especially important on low-mount starters exposed to bilge humidity.

Manifold Flange Spacer Gasket (Marine)

When riser geometry demands a spacer, the spacer gasket maintains a smooth gas path while sealing cooling jackets in adjacent parts. Always confirm that the chosen spacer and gasket combination does not intrude into exhaust flow.

General-Purpose Gaskets Used on the 16V92 Turbo

Some catalog entries are “general” by name but are commonly used across multiple interfaces on the 16V92 Turbo for diagnostics or minor reseals. They are invaluable during sea-trial troubleshooting when you need to isolate and correct small weeps quickly.

Sealants, Adhesives & Consumables for the 16V92 Turbo

High-tack gasket spray

Helps position paper/fiber gaskets—spray a thin, even layer; avoid excess that could squeeze into passages.

Gasket makers (3H, silicone sensor-safe, high-temp RTV, ultra-blue)

Use the specified product for each joint. Sensor-safe formulas protect monitored installations; high-temp RTV belongs near exhaust/turbo heat. Respect skin and cure times.

Non-hardening pliable sealant

Ideal where you anticipate later service—remains flexible and allows future disassembly without tearing the joint.

Threadlocker (high strength)

Apply where procedure calls for it to prevent fastener loosening from vibration. Clean, dry threads only.

Cold-weld epoxy

For non-pressurized, non-structural emergency stabilizations away from flow paths; not a substitute for proper repair, but useful to secure a surface until yard time.

Engine enamel (Detroit green)

Once the reseal is complete and leak-free, a proper enamel finish protects metal and makes future leak detection easier.

Installation Best Practices (Specific to the 16V92 Turbo)

Surface prep

-

Remove old material completely without gouging.

-

Degrease with a lint-free wipe; avoid fibers on sealing lands.

-

Correct pitting or warpage rather than relying on extra sealant.

Dry-fit verification

-

Offer the gasket and mating parts together without sealant to confirm bolt pattern and flow-path clearance.

-

Use dowels where provided to keep alignment true during torque.

Torque patterns & stages

-

Heads, manifolds, and pans require cross-pattern tightening in 2–3 stages to the final value.

-

Re-check after heat-soak if the procedure specifies.

Rotation-specific checks

-

Confirm rotation before choosing rear seals; incorrect lip orientation causes immediate leaks.

Oversize strategy

-

If a crank journal is grooved, do not gamble on a standard seal. Pair the oversize seal with the correct wear sleeve to restore factory contact.

Troubleshooting Leaks on the 16V92 Turbo

Oil

-

Rear area oily: Could be rear main seal, flywheel housing cover, or the housing-to-gear interface. Clean, run, and inspect with a mirror and light to localize before parts replacement.

-

Upper engine mist: Often rocker cover gasket creep or a warped cover flange; install the correct aluminum-cover gasket and correct flange distortion.

-

Pan seepage: Warped rails are common—straighten rails, replace gaskets, and torque correctly.

Coolant

-

Block plug chalk: Replace the block plug gasket and re-pressure test.

-

Water rail weep: Pitted rail surfaces need proper prep or component replacement; a new gasket alone won’t save a pitted joint.

-

Pump faces: If a new gasket still seeps, verify shaft play and face flatness.

Exhaust

-

Soot at riser joint: Resurface, fit the correct riser gasket, and torque from center outward in stages.

-

Gasket burn: A gasket lip intruding into the gas path will burn away; ensure correct OD/ID match and precise alignment.

Turbo lubrication

-

Oil in compressor housing: Often an oil return restriction or mis-seated return gasket. Replace both supply and return gaskets together and confirm the return has proper downhill fall with no kinks.

Maintenance Planning for the 16V92 Turbo (Gaskets & Seals)

Routine service

-

Inspect rocker covers, inspection covers, and block plugs at every service interval.

-

Check turbo oil line gaskets and riser gasket for early signs of sweating or soot.

-

Review raw water pump mounting/plate gaskets for salt tracks.

Major service

-

Replace sectional pan gaskets when the pan is off for bearing checks.

-

Refresh water rail gaskets when thermostats or fresh-water pump work is performed.

-

Evaluate front and rear crank seals; if there is any trace of weep, plan a seal/sleeve update.

Overhaul

-

Use the complete overhaul kit to standardize materials and minimize missed items.

-

Replace liner seals with correct lubrication and guided insertion.

-

Resurface or replace warped covers/rails to avoid repeat leaks.

Ordering Checklist (Tailored to the 16V92 Turbo)

-

Complete overhaul gasket kit (for full reseal/rebuild)

-

Cylinder head gasket kits (four total for the engine)

-

Rocker cover gaskets/kits for aluminum covers (new-style profile)

-

Front and rear crank seals (standard or oversize, single or double lip as required)

-

Rear crank wear sleeve (if a groove is present)

-

Turbocharger riser gasket, oil supply gasket, and oil return gasket

-

Water rail (manifold) gasket; fresh water pump cover gasket

-

Raw water pump mounting gasket and plate gasket

-

Oil pan gaskets for front and rear lower sections (correct quantity)

-

Oil pump inlet gasket; oil pick-up tube gasket

-

Governor cover gaskets (top and spring cover) and hydraulic interface gasket

-

Flywheel housing cover gasket; housing-to-gear interface gasket matched to the installation

-

Marine manifold flange/spacer gaskets and JT-92 style if used on your setup

-

Block plug gasket(s)

-

Sealants/consumables: high-tack spray, specified RTVs, non-hardening sealant, threadlocker, and engine enamel

Why Buy Your 16V92 Turbo Gaskets from Diesel Pro Power

-

Focused guidance for the 16V92 Turbo: Everything on this page is curated and explained only for the 16V92 Turbo so you’re not wading through unrelated fitments.

-

Matched materials you can trust: Gaskets and seals with consistent crush, heat tolerance, and chemical resistance suitable for the turbocharged two-stroke environment.

-

In-stock readiness: Reduce downtime with components ready to ship when your service window opens.

-

Rotation & oversize expertise: We’ll help you identify rotation and decide when an oversize seal with a wear sleeve is the best long-term solution.

-

Marine-specific nuances covered: From riser and manifold gasket geometry to housing-to-gear interfaces, you get parts and advice that reflect real 16V92 Turbo marine use.

-

End-to-end consumables: Pick up the correct sprays, RTVs, threadlocker, and enamel alongside your gaskets so the job finishes right the first time.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588