Parts for Detroit Diesel 371 Non-Turbo - (4 Valve Head Type) - Cylinder head Section

Loading...

Loading... -

Detroit Diesel cylinder head for 371, 6V71

5102769B

REBUILT, bare - Sold with refundable core deposit. See detailsPrice: $ 2,630.88 -

Detroit Diesel cylinder head for 371, 6V71

5102769V

REBUILT, with valves & springs - Sold with refundable core deposit. See detailsPrice: $ 2,875.74 -

-

-

-

-

-

-

-

-

-

Detroit Diesel Rocker cover gasket kit, for 3-71, 6V71, 6V92, and 12V92

5149510

For use with aluminum rocker covers. New stylePrice: $ 70.50 -

-

-

-

-

Detroit Diesel Rocker cover gasket for 3-71 and 6V71

5143405

For tin cover, old style - black rubber

Price: $ 19.39 -

-

-

-

-

-

-

Regulator Screw - Valve Bridge for Detroit Diesel Engines

5129101

Precision-threaded — for valve bridge; fits Detroit Diesel 71 & 92 Series.Price: $ 8.88 -

-

Kent Moore flaring die for Detroit injector tube installation

J-5286-6

This flaring die is part of an injector tube reconditioning kit.Price: $ 191.25 -

-

-

-

Spring, Push Rod for Detroit Diesel 53, 71 & 92 series engines

5186858

2 5/8" Free Length, .177" Wire Dia., 11 Coils, R.H. HelixPrice: $ 9.03 -

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

Detroit Diesel Fuel Line (Short) for Series 71 and 92

5111526

Short. Each engine uses short and long fuel lines

Price: $ 11.37 -

Detroit Diesel Fuel Line (Long) for Series 71 and 92

5111527

Long. Each engine uses short and long fuel lines

Price: $ 11.97 -

Socket To Install & Remove Injector Fuel Lines For Detroit Diesel 53, 71, 92

J8932B

.Price: $ 154.53 -

Detroit Diesel Elbow

8924161

45 degree Inverted flare elbow - with no restriction - 1/4 X 3/8

Price: $ 22.48 -

Detroit Diesel Suction Elbow for Engine

8924155

Fuel pump 90 degree Inverted flare elbow - with no restriction - 3/8 x 1/2

Price: $ 20.28 -

-

-

-

Temperature switch for Detroit Diesel, Cummins, Caterpillar engines

5146080

Closes at 205 degrees Fahrenheit.Thread size is 1/2 NPTPrice: $ 97.19 -

Green Paint for Detroit Diesel Engines

26006

Available for ground shipping only in USA and CanadaPrice: $ 12.46 -

-

Parts for Detroit Diesel 3-71 Non-Turbo (4-Valve Head Type) – Cylinder Head Section

The Detroit Diesel 3-71 engine is part of the legendary Series 71 family—known worldwide for its reliability, long service life, and easy serviceability. The “3-71” designation refers to a three-cylinder, two-stroke diesel engine with a 4.25-inch bore and a 5-inch stroke, producing roughly 85–113 horsepower depending on configuration and application. The 4-valve head variant offers superior airflow and combustion efficiency compared to the earlier 2-valve design, making it popular in marine, industrial, and generator applications.

The cylinder head is at the core of every engine’s performance and efficiency. On the Detroit Diesel 3-71, it governs airflow, fuel delivery, and exhaust cycles. Maintaining a properly functioning head assembly—complete with quality valves, guides, springs, and gaskets—is crucial to sustaining compression and preventing costly downtime.

Diesel Pro Power offers a complete selection of Detroit Diesel 3-71 4-Valve cylinder head parts, all designed for precision fit, durability, and backed by the trust of over 40,000 satisfied customers worldwide.

Complete Cylinder Head Assemblies

The rebuilt bare cylinder head for the Detroit Diesel 3-71 and 6V71 engines is thoroughly inspected, pressure-tested, and machined to factory specifications. Each head undergoes cleaning, crack detection, and dimensional checks before being resurfaced. This version is supplied bare—without valves, guides, or springs—ideal for engine builders who prefer to install their own valvetrain components or reuse existing parts after inspection.

All rebuilt heads are sold with a refundable core deposit, ensuring customers receive a high-quality remanufactured product while supporting sustainable reuse of castings.

Rebuilt Cylinder Head – With Valves and Springs

This head comes completely assembled with new or remanufactured valves, seats, guides, and springs already installed. It’s an excellent choice for technicians or operators who want a ready-to-install component that minimizes downtime. Every valve is precision-ground and seated for proper compression sealing, and springs are load-tested to maintain consistent valve operation at all RPMs.

Like all Detroit Diesel heads from Diesel Pro Power, it’s sold with a refundable core deposit, reflecting Diesel Pro’s commitment to environmentally responsible remanufacturing.

Rebuilt Cylinder Head – Complete Assembly

The complete rebuilt cylinder head for the 3-71 and 6V71 engines comes fully assembled with the rocker gear, bridges, and injector tubes installed. This option provides the fastest path to getting your engine back in service—just remove the old head, install the new one, torque to specification, and set the valve and injector lash.

Every unit is fully tested for coolant integrity and valve performance, ensuring factory-level performance out of the box.

Cylinder Head Hardware and Components

Exhaust valves for the Series 71 engines are hardened to resist pitting and corrosion from high exhaust gas temperatures. The “U”-type valve is specifically designed for the uniflow scavenging characteristic of the 3-71 two-stroke cycle, ensuring efficient exhaust evacuation.

Valve Seals and Guides

Each cylinder uses four valve seals—two for the intake and two for the exhaust valves—to prevent oil from entering the combustion chamber. Diesel Pro’s valve seals for the 71 and 92 Series are manufactured from high-temperature Viton material for exceptional durability.

Valve guides maintain perfect valve stem alignment and are machined from high-strength bronze or cast iron alloy for optimal lubrication retention and wear resistance.

Valve Springs and Seats

Valve springs are critical for maintaining proper valve timing and seating pressure. Each spring is engineered to meet OEM tension standards, preventing valve float at higher engine speeds. Valve seat inserts are precision-ground for consistent valve sealing, contributing to improved compression and combustion efficiency.

Proper clamping force is essential to sealing the head gasket and preventing coolant or combustion gas leaks. Diesel Pro’s high-grade 5/8"-11 x 5-3/8" head bolts are manufactured from heat-treated steel and meet or exceed Detroit Diesel torque specifications.

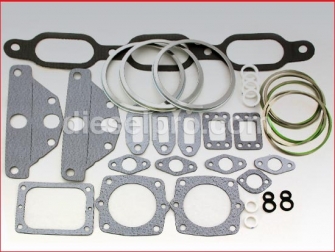

Cylinder Head Gaskets and Seals

The head gasket kit for the 3-71 includes all necessary seals, O-rings, and gaskets for a complete cylinder head installation. It’s designed to withstand high combustion pressures and prevent oil and coolant cross-contamination.

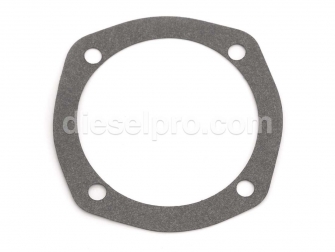

Valve Cover Breather Seal and Rocker Cover Gaskets

Valve cover breather seals prevent oil mist from escaping through the crankcase vent system. Rocker cover gaskets are available in both the old-style black rubber for tin covers and the new-style gray rubber for aluminum covers.

The rocker cover gasket kit includes seals and retainers for both styles, allowing for a secure fit and leak-free performance.

Water Manifold and Governor Gaskets

Water manifold gaskets ensure coolant passages are properly sealed, preventing leaks at the head-to-manifold interface. The governor gasket maintains a tight seal between the cylinder head and the governor housing—critical for stable engine speed control.

Cylinder Head Water Outlet Plate

The water outlet plate and its associated gasket prevent coolant leaks where the upper coolant rail connects to the cylinder head. Diesel Pro provides precision-cut plates with durable sealing surfaces to guarantee reliability under thermal cycling.

Valve Train Components

Valve Bridges and Caps

The exhaust valve bridge distributes rocker arm force evenly across paired exhaust valves, ensuring synchronized operation and equal valve lift. Bridges are precisely machined and hardened for long-term stability. Valve caps, installed on top of the valve stem, prevent wear and distribute spring loads evenly.

Rocker arms translate camshaft motion into valve movement. Diesel Pro offers both left-hand and right-hand rocker arms for the Series 71 and 92 engines. Each arm is machined to tight tolerances for smooth pivot operation. The rocker arm shaft supports all arms within a cylinder head bank and ensures correct oil lubrication through internal oil passages.

Rocker arm brackets secure the rocker assembly to the head. Diesel Pro’s brackets are made from hardened steel and designed for direct fitment on both 71 and 92 series engines. Matching bolts ensure secure clamping and long-term durability.

Push Rod Assemblies and Related Hardware

Push rods transfer cam follower motion to the rocker arms. Diesel Pro stocks OEM-spec push rods, push rod springs, retainers, and spring seats for all Series 71 engines.

-

Push Rod Spring – Controls valve lash movement and maintains alignment.

-

Push Rod Spring Seat (Upper and Lower) – Ensures consistent spring compression.

-

Push Rod Retainer – Holds the push rod securely in the follower socket.

-

Cam Follower Guide – Keeps the cam follower aligned for precise motion transfer.

Fuel System Connections and Fittings

Fuel distribution in the 3-71 relies on a network of fuel jumper lines, connectors, elbows, and restriction fittings. Diesel Pro supplies all the necessary components to restore or upgrade your fuel delivery system.

Fuel Lines

Available in short and long versions, these steel lines connect injectors to maintain even fuel pressure. Each engine uses a combination of both line lengths.

Injector tubes seat inside the cylinder head and direct pressurized fuel into the combustion chamber. Diesel Pro’s tubes are precision-formed and compatible with factory injector flaring tools.

Fittings and Connectors

Restriction fittings (R70 and R80) control fuel return pressure to optimize injector performance. Diesel Pro offers both 70-lb and 80-lb versions, along with unrestricted elbows for supply lines.

Specialized Tools

For proper installation, Diesel Pro provides a Kent-Moore flaring die tool to reseat or refurbish injector tubes, as well as socket wrenches for removing and installing fuel lines without damaging fittings.

Cooling System Components

Cylinder head components interface closely with the engine’s cooling system. The water manifold studs and gasketsensure secure sealing, while the water outlet plate channels coolant flow efficiently. For comprehensive service, Diesel Pro also offers:

-

Water Pump Gasket – Seals the fresh water pump to the cylinder head.

-

Temperature Switch – Activates at 205°F to protect the engine from overheating.

-

Drain Cock Fittings – Allow easy draining of coolant during maintenance.

Finishing Components and Accessories

The 2-inch oil filler cap seals the top of the valve cover, preventing oil spray and contamination while allowing easy refilling.

Diesel Pro’s Detroit Green engine paint matches OEM color and resists high temperatures, providing corrosion protection and a professional finish.

Fasteners and Nuts

From valve bridge regulator nuts to fuel connector washers, every fastener in this section is made to exact thread and strength specifications. Proper hardware ensures reliable operation across heat cycles and vibration conditions.

Cylinder Head Reassembly and Installation Notes

When reinstalling or replacing a cylinder head on a Detroit Diesel 3-71 engine, technicians should follow a systematic approach:

-

Inspect the Block Surface – Ensure flatness and cleanliness.

-

Install the Head Gasket Kit – Align coolant and oil passages carefully.

-

Position the Head – Lower it evenly to avoid pinching the gasket.

-

Torque Head Bolts – Follow Detroit Diesel torque sequence and specification.

-

Adjust Valves and Injectors – Use a feeler gauge (.002"–.025") to calibrate valve lash precisely.

-

Check for Leaks – After initial startup, verify coolant, fuel, and oil connections are secure.

Proper reassembly ensures optimal compression and long service life. Diesel Pro Power supplies everything needed for a complete and professional job—from gaskets to rocker arms—delivered quickly and reliably worldwide.

Why Choose Diesel Pro Power for Your Detroit Diesel 3-71 Cylinder Head Parts

Diesel Pro Power is the most trusted global source for Detroit Diesel replacement parts. With over 40,000 satisfied customers, the company’s commitment to quality and customer support is unmatched. Here’s why professionals choose Diesel Pro:

-

Factory-Grade Quality: All rebuilt and new cylinder heads are pressure-tested and machined to OEM standards.

-

Global Shipping: Fast, reliable delivery to any location, with same-day processing on most in-stock items.

-

Expert Support: Dedicated diesel engine specialists available to help identify parts, confirm compatibility, and guide installation.

-

Sustainability: Core-return program reduces waste while providing cost savings to customers.

-

Comprehensive Inventory: Every component—from valves to flaring tools—is available in one place.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588