Parts for Detroit Diesel 453 Non-Turbo - Engine Water Pump Section

Loading...

Loading... Parts for Detroit Diesel 453 Non-Turbo – Engine Water Pump Section

The Detroit Diesel 453 Non-Turbo engine is one of the most enduring two-stroke powerplants ever produced by Detroit Diesel’s 53-series family. Built on the same rugged foundation as its smaller 3-53 and larger 6V53 siblings, the 453 was engineered for dependability in industrial, generator, and marine applications where efficiency and consistent cooling are paramount.

At the center of this reliability stands the fresh-water pump and cooling system, which circulate coolant through the cylinder block, cylinder heads, and heat exchanger to maintain ideal operating temperatures under load. Diesel Pro Power offers a complete line of Detroit Diesel 453 Non-Turbo engine water pumps, gaskets, repair kits, thermostats, coolant hoses, fittings, and clamps, all organized by rotation and configuration for precise compatibility.

Understanding the Detroit Diesel 453 Cooling System

The Detroit Diesel 453 Non-Turbo engine uses a closed-loop fresh-water cooling system that transfers heat from the engine block to a heat exchanger or radiator. Proper coolant circulation ensures consistent temperature control, prevents hot spots, and maintains oil viscosity for optimal lubrication.

A failing water pump or worn gasket can lead to coolant leaks, overheating, and ultimately, major component failure. Regular inspection and maintenance of the fresh-water pump assembly—including bearings, seals, impellers, and gaskets—are vital to the longevity of the 453 engine.

The cooling system comprises:

-

Fresh-water pump (left- or right-hand rotation)

-

Mounting gasket and hardware

-

Thermostat and thermostat gasket

-

Coolant hoses and clamps

-

Drain fittings, radiator caps, and necks

-

Temperature switch and gauges

Each component works together to stabilize temperature, enabling the engine to perform reliably in industrial machinery, stationary generators, and marine propulsion setups.

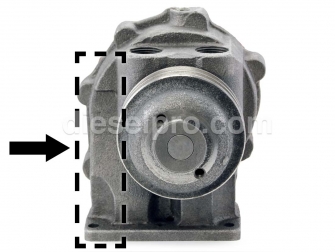

Fresh-Water Pumps for the Detroit Diesel 453 Non-Turbo

Left-Hand Rotation Pump

Detroit Diesel Engine Water Pump – Left Hand Rotation – New

Compatible with 353, 453, 6V53, 8V53 engines

The left-hand rotation pump is designed for Detroit Diesel 453 engines where rotation direction matches counter-clockwise pump drive. Manufactured to OEM-grade tolerances, this pump ensures high-flow coolant circulation through all four cylinders, maintaining consistent temperature across cylinder liners and cylinder heads.

Key features include:

-

Precision-machined impeller for efficient coolant movement.

-

Heavy-duty bearings and seals for long service life.

-

Corrosion-resistant cast housing designed for marine and industrial environments.

-

Direct-fit design for straightforward installation on all non-turbo 453 engines.

Right-Hand Rotation Pump

Detroit Diesel Engine Water Pump – Right Hand Rotation – New

Compatible with 353, 453, 6V53, 8V53 engines

The right-hand rotation pump suits configurations where pump drive rotation is clockwise. Maintaining correct rotation orientation is crucial: installing the wrong rotation pump will result in insufficient coolant circulation.

Each right-hand pump undergoes dynamic balance testing to ensure vibration-free performance and precise seal seating.

Mounting Gasket for Detroit Diesel 53 Series Water Pumps

A reliable seal between the pump housing and engine block is essential to prevent coolant leaks and maintain pressure.

Detroit Diesel Mounting Gasket – 53 Series Engines provides:

-

High-temperature composite material resisting coolant and oil degradation.

-

Pre-cut bolt patterns for precise alignment.

-

Easy installation during pump replacement or service.

Replacing the gasket every time a pump is removed ensures the new assembly operates leak-free and prolongs service intervals.

Fresh-Water Pump Repair Kits

Over time, seals and bearings wear within the pump housing. Rather than replacing the full assembly, operators can restore function with Detroit Diesel Fresh-Water Pump Repair Kits.

Left-Hand Rotation Pump Repair Kit

This kit includes OEM-grade bearings, mechanical seals, gaskets, and hardware tailored to the left-hand rotation pump. Rebuilding saves costs while retaining the original pump body. Technicians appreciate this option for engines in remote installations where sourcing a new pump may take longer.

Right-Hand Rotation Pump Repair Kit

Designed for right-hand rotation models, this kit allows full refurbishment of the impeller shaft, bearings, and seals. Diesel Pro Power advises replacing these components during major overhauls to avoid future coolant loss.

Thermostat and Thermostat Gasket for Detroit Diesel 453

The thermostat regulates coolant flow based on temperature, ensuring the engine reaches and maintains optimal operating heat.

Detroit Diesel Thermostat – 170 Degrees Fahrenheit is calibrated specifically for 53-series engines, including the 3-53, 4-53, and 2-71 models. Its brass construction provides consistent expansion response and durability under two-stroke operating pressures.

Pair it with the Detroit Diesel Thermostat Gasket to guarantee a perfect seal between the thermostat housing and cylinder head. Even small leaks in this area can reduce system pressure and lead to erratic temperature fluctuations.

Drain Fittings and Radiator Caps

Drain Cock Fitting – 1/4"

This precision-threaded fitting allows controlled coolant draining for maintenance or winterization. It’s corrosion-resistant and compatible with standard radiator and block drain ports on Detroit Diesel 453 engines.

Radiator Cap – 7 lb Pressure

The radiator cap maintains system pressure, raising coolant boiling point and preventing vapor lock. A 7-lb cap is standard for most 53-series systems. Replace the cap periodically, as spring tension can weaken with age.

Radiator Cap Necks

Available in both small and large diameters (1.63–2.22 inches), these necks provide correct fitment for replacement radiators or custom cooling setups. Proper neck alignment ensures the pressure cap seats evenly to maintain seal integrity.

Radiator Cleaner and System Maintenance Fluids

Deposits of rust, scale, and corrosion inside coolant passages reduce heat transfer efficiency. Detroit Diesel Radiator Cleaner (18E) is formulated for aluminum and cast-iron systems, breaking down deposits without damaging seals or hoses. Routine cleaning every 12–18 months can restore coolant flow and prevent overheating.

Available for ground shipping in the USA and Canada, this cleaner is a recommended maintenance step whenever installing a new pump or thermostat.

Temperature Switch – Automatic Protection

The Temperature Switch (205°F Close point) protects engines from overheating by triggering alarms or shutdowns in generator and marine applications. With a ½-inch NPT thread, it easily integrates into cylinder-head ports or coolant lines, providing early warning of temperature spikes.

Detroit Diesel Green Engine Paint

After maintenance, protect external metal surfaces with Detroit Diesel Green Engine Paint. Resistant to heat, oil, and chemicals, it prevents corrosion and restores the factory appearance of the 453 Non-Turbo engine. Perfect for both marine and industrial restorations.

Premium Silicone Coolant Hoses

Efficient coolant flow depends on flexible, high-temperature-resistant hoses. Diesel Pro Power’s silicone coolant hoses exceed OEM temperature and pressure ratings, ensuring durability under continuous operation. Available diameters from ¾-inch to 4 inches accommodate all coolant circuit sizes on Detroit Diesel 453 engines.

Each hose is one foot long—ideal for precise replacement without waste. Silicone hoses offer several advantages over standard rubber:

-

Withstand temperatures up to +500 °F.

-

Resist cracking, swelling, and chemical degradation.

-

Maintain consistent internal diameter under pressure.

-

Provide long-term performance in both marine and stationary power systems.

Proper hose selection minimizes coolant turbulence and ensures the pump maintains optimal pressure throughout the block and cylinder head network.

Hose Clamps – Precision Fit for Every Diameter

Every coolant line depends on tight, corrosion-free connections. Diesel Pro Power stocks an extensive range of hose clamps designed to match the full diameter range of Detroit Diesel 453 coolant and fuel lines.

Key Clamp Sizes and Applications

-

Clamp 10H: For small 9/16"–1-1/16" hoses, ideal for bypass lines and heater circuits.

-

Clamp 5104592: For 1"–1.5" hoses, common on water return lines.

-

Clamp 3412320: For 11/16"–1¼" diameter, suitable for smaller coolant lines.

-

Clamp 4920417: For 13/16"–1¾" hoses—used on suction and return connections.

-

Clamp 3922846 / 3922847: For 1-5/16"–2½" range—typical on main radiator or heat exchanger connections.

-

Clamp 5188036: For 2-7/8"–3.5" applications—heavy-duty marine water lines.

All clamps are stainless-steel or zinc-plated to resist corrosion in harsh marine environments. Replace clamps during hose changes to ensure equal compression and leak-free seals.

Gauges for Monitoring Cooling Performance

Diesel Pro Power offers mechanical and electrical gauges to track coolant temperature, pressure, and other critical engine parameters.

-

Mechanical Gauges – Rugged, cable-driven designs ideal for direct engine-panel installations.

-

Mechanical Gauges with Alarms – Include adjustable warning contacts for automatic alerts.

-

Electrical Gauges (12 V & 24 V) – Suitable for marine consoles and industrial control panels.

Monitoring coolant temperature helps operators detect flow restrictions or pump wear before overheating occurs.

Installing a New Detroit Diesel 453 Water Pump

Proper installation ensures longevity and performance. Below is a simplified installation guide following Detroit Diesel service practices:

-

Drain the cooling system. Open the drain cock fitting and remove the radiator cap to release pressure.

-

Remove hoses and clamps. Label each connection to simplify reassembly.

-

Detach the old pump. Remove mounting bolts and gasket remnants from the engine block surface.

-

Inspect components. Check drive gear, pulley, and mounting surfaces for wear or corrosion.

-

Install new gasket. Lightly coat with approved sealant if required.

-

Mount new pump. Align bolt holes precisely and tighten in a crisscross pattern to manufacturer torque specifications.

-

Reconnect hoses and clamps. Ensure clamps are evenly tightened and positioned behind hose beads.

-

Refill coolant system. Use a 50/50 mix of ethylene glycol and distilled water, ensuring no air pockets remain.

-

Test run. Verify flow, temperature stability, and absence of leaks.

Routine re-torquing of bolts after initial run-in ensures gasket seating and prevents future seepage.

Common Symptoms of Water Pump Failure on Detroit Diesel 453 Engines

Recognizing early signs of wear prevents costly downtime:

-

Coolant leakage from the weep hole or mounting area.

-

Overheating due to impeller erosion or bearing failure.

-

Noisy bearings producing whining or grinding sounds.

-

Reduced coolant flow evident by fluctuating temperature readings.

-

Corrosion buildup around the pump housing.

Timely replacement with Diesel Pro Power OEM-grade pumps restores performance and reliability.

Cooling System Maintenance Tips

-

Check coolant level daily before engine start.

-

Flush system annually using approved radiator cleaner to remove mineral buildup.

-

Inspect hoses and clamps for softness or cracks every 250 hours.

-

Replace thermostat every two years or during major overhauls.

-

Use only approved coolant mixtures—50/50 ethylene glycol and distilled water or equivalent extended-life coolant.

-

Maintain correct pressure cap rating (7 lbs for most 53-series).

-

Monitor temperature gauge during operation; sustained readings above 200°F indicate restricted flow.

Following these practices maximizes pump life and protects cylinder liners from heat stress and cavitation.

Detroit Diesel 453 Non-Turbo Applications

The 453 engine powered:

-

Industrial generators and compressors

-

Construction machinery such as loaders and excavators

-

Marine auxiliary engines and propulsion in small vessels

-

Agricultural and forestry equipment

In every configuration, consistent cooling is critical. Whether the engine operates in a fixed installation or marine environment, maintaining an efficient water pump and sealed cooling system prevents unplanned shutdowns.

Why Choose Diesel Pro Power for Detroit Diesel 453 Cooling System Parts

Selecting the right supplier matters as much as selecting the right part. Diesel Pro Power stands as the most trusted online source for Detroit Diesel parts, serving operators and mechanics in over 180 countries.

Global Reputation

Over 40,000 satisfied customers worldwide rely on Diesel Pro Power for authentic, high-quality Detroit Diesel parts. Every component in this catalog meets or exceeds OEM standards for material strength, precision, and fit.

Premium Aftermarket Quality

Water pumps, repair kits, gaskets, thermostats, and hoses are sourced from leading manufacturers and inspected for dimensional accuracy. Components are designed to withstand the high-RPM demands of two-stroke Detroit Diesel engines.

Complete Catalog Organization

Our digital catalog is structured by engine model and system, allowing users to navigate directly to cooling, fuel, or lubrication sections. Each item includes detailed descriptions, rotation information, and multilingual terminology for easy international reference.

Fast Worldwide Shipping

Diesel Pro Power maintains large-scale inventory and streamlined logistics, ensuring rapid delivery to ports, marinas, and industrial sites across the globe. Same-day shipping is available on most in-stock parts, minimizing downtime.

Expert Technical Support

Our specialists assist with:

-

Selecting correct pump rotation (LH vs RH).

-

Identifying matching gaskets and repair kits.

-

Determining thermostat ratings for ambient conditions.

-

Diagnosing flow or overheating issues.

-

Recommending compatible hoses and clamp sizes.

Each inquiry receives personalized attention from technicians familiar with legacy Detroit Diesel systems.

Reliability and Customer Confidence

Purchasing from Diesel Pro Power means investing in quality, longevity, and expert support. We stand behind every product with detailed documentation, diagrams, and clear warranty information.

Summary of Available Components

|

Category |

Description |

Rotation / Size |

Compatibility |

|

Fresh-Water Pump |

New replacement pump |

LH / RH |

353 – 453 – 6V53 – 8V53 |

|

Mounting Gasket |

Seals pump housing |

— |

53-Series |

|

Repair Kit |

Bearings & seals |

LH / RH |

53-Series |

|

Thermostat |

170°F opening temp |

— |

3-53 / 4-53 / 2-71 |

|

Thermostat Gasket |

Housing seal |

— |

All 53-Series |

|

Drain Cock |

¼-inch fitting |

— |

All 53-Series |

|

Radiator Cap & Neck |

7 lb pressure |

Small / Large |

53-Series |

|

Radiator Cleaner |

Corrosion remover |

— |

All cooling systems |

|

Temperature Switch |

Closes 205°F |

½ NPT |

Multi-brand |

|

Detroit Green Paint |

Finish coat |

— |

Detroit Diesel engines |

|

Silicone Hoses |

¾" – 4" diameter |

— |

Cooling lines |

|

Hose Clamps |

Various sizes |

— |

Fuel & coolant lines |

|

Gauges |

Mechanical / Electrical |

12V / 24V |

All applications |

The Diesel Pro Power Difference

Diesel Pro Power is more than a parts supplier—it’s a partner dedicated to keeping legacy Detroit Diesel engines alive. The Detroit Diesel 453 Non-Turbo continues to operate around the world because owners have access to dependable parts, expert knowledge, and unmatched customer service.

With decades of experience supporting the 53-series family, Diesel Pro Power ensures that every water pump, gasket, and hose in this catalog meets the strict standards that Detroit Diesel mechanics expect. When reliability, precision, and speed matter most, Diesel Pro Power delivers.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588