Parts for Detroit Diesel 471 Non-Turbo - (2 Valve Head Type) - Gasket Section

Loading...

Loading... Parts for Detroit Diesel 4-71 Turbo – Gasket Section

Keeping a Detroit Diesel 4-71 Turbo dry, tight, and on-boost starts with the right gaskets and seals—installed the right way. Below you’ll find a comprehensive, engine-specific guide that mirrors the exact components available in this catalog section and explains what each gasket or seal does, when to replace it, how to prep the surfaces, and how to choose materials or lip configurations (single vs. double, standard vs. oversize). The focus here is the turbocharged 4-71 (“4-71 Turbo”) in both industrial and marine service, with compatibility notes kept brief where an item also fits neighboring 71-Series engines. Use this as your field manual for smart selection and reliable installation.

What’s in This Gasket Section (and How to Use It)

This section aligns with the items you see above—starting with complete engine gasket solutions, moving into inspections and small covers, then into crankshaft front/rear sealing, front lower cover, cylinder head and rocker cover seals, water and oil system gaskets, blower and governor interfaces, exhaust and turbo mating gaskets, oil pan and filter adapter gaskets, thermostat and pump interfaces, flywheel housing covers, raw-water and heat-exchanger interfaces for marine builds, and finally consumables and sealants that tie a proper overhaul together. Read the topical guidance below, then click into the individual product(s) you need.

Engine-Wide Coverage: Overhaul, Inspection & Small Cover Gaskets

For Detroit Diesel 4-71 Turbo

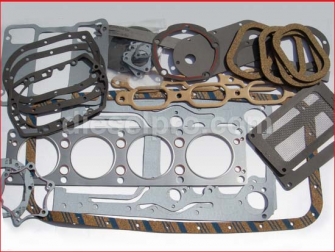

Overhaul Gasket Kit (Full Engine Coverage)

When the 4-71 Turbo is coming apart for rings, liners, bearings, or a head job, a comprehensive overhaul gasket kit is your efficiency play. It packages the high-use soft parts—head gaskets or head set, intake/exhaust and coolant junction gaskets, oil pan strips, timing/front cover papers, valve/rocker cover seals, water manifold papers, governor and accessory interfaces, and the small, easy-to-forget gaskets that can stall reassembly. A complete kit reduces mismatches and saves time sourcing one-off pieces across the engine. It’s also your best assurance that paper thicknesses and sealing materials were chosen to live in Detroit two-stroke fuel, oil, and coolant environments.

Inspection Cover Gasket

During troubleshooting or periodic checks (especially on high-hour marine or generator sets), the block inspection cover is frequently disturbed. If there’s any evidence of cork shrinkage, paper tearing, or surface nicking after removal, install a fresh inspection cover gasket. A leak here will often weep oil down the block, get blown rearward by the fan, and masquerade as a rear main issue—so it’s inexpensive insurance to renew whenever you open the cover.

Balance Weight Cover Gasket

The balance weight (counterweight) cover seals a small but pressurized and splash-oiled cavity. The gasket lives in hot oil mist and can harden over time. If you’re chasing a persistent drip near the front side plate or notice staining at the lower front-side of the block, replacing this small cover gasket often solves it. Clean both surfaces with a lint-free wipe and brake-clean type solvent; avoid excessive sealant that can squeeze into the cavity.

Crankshaft Sealing: Front & Rear, Single vs. Double Lip, Standard vs. Oversize

For Detroit Diesel 4-71 Turbo

Front Crankshaft Seal (Universal Rotation)

The front seal on the 4-71 Turbo must tolerate both crank snout surface speed and the additional ventilation load of a boosted two-stroke. “Universal rotation” seals are designed to sweep oil inward regardless of rotation direction—critical in marine applications and in installations where rotation specifics vary by build. If your harmonic balancer shows sling-off, or you see a circular oil pattern behind the pulley, the front seal is suspect. Always inspect the crank hub for grooves; if grooved, consider a sleeve or hub replacement.

Rear Crankshaft Seal – Standard Single Lip

The rear main is a common source of “mystery” leaks that look like flywheel housing or rear pan leaks. A standard single-lip seal is correct for many stock rebuilds when the crank sealing surface is still in spec. Measure the OD/ID carefully and confirm the crank journal condition. If you see a palpable groove where the last lip rode, upgrading to a sleeve and/or oversize seal is smart.

Rear Crankshaft Seal – Oversize Single Lip

Choose an oversize single-lip seal when a standard seal won’t hold on a worn journal or where prior seal groove is present. On a turbocharged 4-71, crankcase pressure transients can be a touch higher than naturally aspirated setups, so a precisely sized lip helps. Clean the bore, clock the seam per manual guidance, and lubricate the lip with clean engine oil at install.

Rear Crankshaft Seal – Standard Double Lip

A double-lip design provides an extra barrier: one lip handles oil retention while the other helps exclude dust and clutch or bell-housing debris. This can be valuable in dusty off-road or marine bilge environments. If your 4-71 Turbo sees harsh service, the double-lip option adds resilience without a big cost penalty.

Rear Crankshaft Seal – Oversize Double Lip

When you need the protective benefit of a double-lip and the dimensional take-up of oversize, this seal is the go-to. It’s the most forgiving choice for marginal crank journals, but still demands good surface prep and concentric installation.

Oversize Sleeve (Rear for 71-Series)

A sleeve restores the sealing land on a grooved or pitted crank hub/journal so your new seal isn’t sacrificed in the first hours of run-in. Lightly polish the installed sleeve to eliminate high spots and always test-fit the seal dry before final lubrication and press-in. Sleeves are inexpensive compared to pulling the crank.

Front Lower Cover Gasket

Oil seepage from the lower front cover can be mistaken for a front main leak. Before condemning the seal, reseal the front lower cover with a proper paper or fiber gasket and a light coat of tack if required by the manual. Ensure dowels are present and seating true—misaligned covers shear gaskets.

Pro Tips for Crank Seals on a 4-71 Turbo

-

Verify crankcase breather function; excessive crankcase pressure will defeat even new seals.

-

Always lube the lip with clean oil; a dry start burns a groove almost immediately.

-

Use a proper driver or a large, flat ring to press the seal squarely; tapping around the perimeter risks distortion.

Cylinder Head & Valve Train Covers

For Detroit Diesel 4-71 Turbo

Cylinder Head Gasket Kit

A turbocharged 4-71 imposes higher cylinder pressures compared to naturally aspirated variants, so head sealing is critical. The head gasket kit provides the primary combustion and coolant passages seal along with related upper-engine gaskets (depending on kit contents). Carefully inspect deck flatness, clean fire rings, and use the correct torque sequence. Re-torque after initial heat cycles if specified for your configuration.

Rocker Cover Kits & Gaskets (New-Style Aluminum vs. Old-Style Stamped)

Detroit two-strokes used both aluminum and stamped steel rocker covers. New-style gray rubber gaskets are tailored for aluminum covers and provide excellent reusability. Old-style black rubber gaskets fit stamped covers and clamp correctly under the narrower flange. Identify your cover type first—mixing styles leads to weeping, especially at the corners. Lay the gasket into the cover with a kiss of weatherstrip adhesive only if needed to hold it during install; avoid loading the head rail with sealant.

Governor-to-Head and Governor-Drive Gaskets

Governor gaskets are thin but crucial: air leaks here can affect rack response and idle stability. Replace the gasket between the head and governor, and the gasket between governor housing and governor drive whenever the assembly is removed. Clean both faces perfectly flat; a razor blade at a shallow angle avoids gouging the aluminum.

Governor Spring Cover & Cap Gaskets

These small round or oval papers prevent oil weep from the spring cavity. Aging cork/rubber will harden and crack—replace during any governor service or calibration.

Blower Interfaces (Critical on a Turbo 4-71)

For Detroit Diesel 4-71 Turbo

Blower Installation Gasket Kit (4-71)

Even in a turbocharged configuration, the Roots blower supplies scavenging air on a two-stroke Detroit. Any leakage at the blower base or screen reduces delivered air and upsets mixture at low and midrange. The 4-71 blower install kit packages the base gasket(s), screen gasket, and related seals so you have everything aligned in one go. Dry-fit the blower to confirm dowel engagement, then torque in sequence to avoid warping.

Blower Screen Gasket & Blower-to-Block Gasket

The screen gasket seals the debris screen frame; the blower-to-block gasket is your main air seal. If you see oil mist around the blower base or hear a faint hiss under boost, the base gasket may be leaking. Don’t reuse a compressed paper gasket once it’s been heat-soaked.

Water, Oil & Cooling-System Interfaces

For Detroit Diesel 4-71 Turbo

Water Manifold (Water Rail) Gasket

The water rail ties multiple coolant ports along the head or block. A leaking rail gasket often shows as a thin trail of coolant staining along the side of the engine. Clean both surfaces, chase bolt holes, and torque evenly—over-tightening one bolt will curl the rail and create a future leak.

Fuel/Water Pump Combination Gaskets

On bracket-mounted accessories, pump gaskets keep oil or coolant from wicking along the mounting face. Replace these when swapping pumps to avoid misdiagnosing a “pump seal” failure that’s actually a flange leak.

Oil Cooler Gaskets

The 4-71 Turbo’s oil cooler maintains viscosity and prevents thermal breakdown under boost. If you see oil in coolant or vice versa (and the head gasket is intact), inspect cooler core integrity and always renew the cooler face gaskets on service. Torque the end cover evenly and recheck after the first hot run.

Oil Filter Adapter Gasket

A tired adapter gasket can drip onto the block and starter. Remove the adapter, clean mating surfaces to bare metal, and install a fresh gasket. Avoid RTV here—paper seals best when dry and flat.

Thermostat Housing & Engine Water Pump Cover Gaskets

Any air drawn into the cooling side can create hot spots in a turbo engine. Replace the thermostat housing gasket whenever the housing is removed; the same goes for the pump cover gasket. Use a light smear of tack only if the surfaces are pitted.

Marine Raw-Water Pump Gaskets (Inlet/Outlet & Plate)

Marine 4-71 Turbo packages typically use a raw-water pump feeding a heat exchanger. Each pump usually needs two identical gaskets (inlet and outlet) plus a plate gasket. Replace all together whenever you service the impeller—reusing old paper invites post-service drips that soak belts and make a mess of the bilge.

Heat Exchanger Gasket Kit (Marine)

If your 4-71 Turbo is heat-exchanger cooled, the tank end-caps and pass-through plates use shaped gaskets or O-rings. A purpose-built kit ensures you have every seal for a proper clean-out and rod-through. Pressure-test the exchanger after reassembly before returning the boat to service.

Exhaust, Manifold, and Turbo Mating Surfaces

For Detroit Diesel 4-71 Turbo

Head-to-Exhaust Manifold Gaskets

On a boosted two-stroke, exhaust pulses are intense; a leaking head-to-manifold junction will whistle, soot the block, and rob energy from the turbo. Replace these gaskets any time the manifold is disturbed. Check manifold straightness with a straightedge—resurface if it’s out.

Marine Manifold Flange Gasket

Marine risers and elbows must remain sealed to keep salt spray and exhaust confined. Measure your flange ID/OD (e.g., 4.25" ID, 6.25" OD on common marine riser gaskets) and use the correctly sized ring.

Turbo Riser Inlet/Outlet Gasket

The turbo riser gasket seals the hot side outlet to the riser. Know your inner and outer dimensions (commonly specified) and verify the bolt pattern. A leak here usually shows as soot around the flange and can drip condensate when cold.

Industrial Manifold Flange Gaskets (3" and 4")

Industrial configurations may use round clamp-up flanges in 3" or 4" sizes. Match by inner diameter; replacing with an undersized gasket constricts flow, while an oversized ID can allow flange overhang and leakage.

Oil Pan, Flywheel Housing, and Adapter Interfaces

For Detroit Diesel 4-71 Turbo

Oil Pan Gasket (4-71 and Rear-Lower on Select V-Configurations)

The pan gasket on a 4-71 seals a wide, thin flange that’s easy to warp. Use a light spread of tack to hold the gasket in place and torque in multiple passes, alternating across the pan. Re-snug after the first heat soak; paper relaxes slightly under oil and heat.

Flywheel Housing Gaskets & Covers

Oil in the bell housing often traces back to a flywheel housing paper or rear main seal. If you’re changing a rear seal, do the housing paper at the same time. For engines that also power marine gears, check that the housing cover for your series is installed with a fresh gasket to prevent bilge mess and to keep the clutch side clean.

Oil Filter Adapter & Starter Gaskets

While small, these gaskets are frequent leakers due to vibration and heat. Renew whenever either component is off the block. A clean, dry paper seal beats excess sealant every time.

Governor & Control-Side Details

For Detroit Diesel 4-71 Turbo

Governor Housing, Drive, Spring Cover, and Cap Gaskets

This cluster of small gaskets controls oil retention and airflow integrity around the governor. Any leak can alter governor behavior or invite dirt. Replace all disturbed papers during governor calibration or when changing racks. Confirm the correct gasket orientation—some are mirror-image.

Hydraulic Governor Gaskets

If your 4-71 Turbo uses a hydraulic governor, the gasket between governor and drive is specific and must be in good condition to maintain hydraulic response. Replace on removal; torque to spec.

Adapter, Mounting & Ancillary Seals

For Detroit Diesel 4-71 Turbo

Adapter and Mounting Gaskets for Water Pumps

Adapter gaskets let you mount accessory pumps while maintaining a sealed interface to the block. These gaskets are often thicker or shaped to accommodate casting steps—use the exact adapter paper to prevent stress cracks from over-torquing mis-fit parts.

Allison Marine Gear Flywheel-Housing-to-Transmission Gasket (SAE #2)

For marine 4-71 Turbo packages mated to Allison M/MH gears with SAE #2 housings, this gasket seals the engine’s flywheel housing to the gear input. Match housing size to avoid chafing or misalignment. Always check dowel fitment and clean both machined faces; a crooked housing will shear the paper and transmit vibration into the gear.

Sealants, Compounds & Consumables (Use Wisely)

For Detroit Diesel 4-71 Turbo

High-Temperature Turbo Jointing Compound

On dry joints around the turbocharger where a compressible gasket is not used, a high-temperature compound fills micro-gaps and resists carbon tracking. Apply a thin, even film; too much extrudes and can flake downstream.

Gasket Sprays & Liquid Gasket Makers

-

High-Tack Spray holds paper gaskets during assembly and improves micro-sealing on slightly pitted faces.

-

Non-Hardening Pliable Sealant is ideal where future disassembly is expected (covers, plates, inspections).

-

Sensor-Safe RTV should be used sparingly on stamped covers and timing plates—thin skins only.

-

High-Temp RTV is reserved for hot flanges outside of turbo temperatures (always check compound rating).

-

Ultra-Blue RTV (Sensor-Safe) is a generalist RTV for cool-side joints where a formed-in-place gasket is appropriate.

Threadlocker (High Strength, Red)

Use on fasteners that should not loosen—manifold studs/nuts, blower mounts, and brackets. Confirm you’ll be able to service later; high-strength threadlocker may require heat to release.

Cold Weld Epoxy (Field Repair)

J-B type epoxies are for emergency patching of non-pressurized housings or to stabilize a pitted cover until proper replacement. Do not rely on epoxy to seal fuel rails, head decks, or cooler faces.

Detroit Green Engine Paint

After a proper degrease and mask, a Detroit-green topcoat prevents rust and simplifies future leak detection by creating a clean background.

Installation Essentials: Techniques That Prevent Comebacks

For Detroit Diesel 4-71 Turbo

Surface Preparation

-

Scrape old gasket material with a plastic or sharp razor scraper at a shallow angle; finish with Scotch-Brite and solvent.

-

Chase threads and blow out blind holes; oil trapped in a blind hole can crack castings when torqued.

-

Check flatness on manifolds and covers—warped parts eat gaskets.

Dry vs. Dressed Gaskets

-

Paper/fiber gaskets on smooth, flat, machined faces often seal best dry or with a mist of high-tack.

-

Do not over-dress; excessive sealant extrudes into oil or coolant passages and can clog jets or coolers.

-

RTV is for specific joints where a formed-in-place gasket is specified; never use RTV on a head gasket.

Torque Patterns & Re-Torque

-

Use cross-pattern torques in 2–3 passes to bring flanges down evenly.

-

Re-check torque on oil pans, rocker covers, and accessory plates after the first heat cycle if permitted by the manual.

Seal Lip Orientation & Lubrication

-

The sealing lip faces the fluid you’re retaining (oil side).

-

Always pre-lube the lip with clean engine oil—never install dry.

-

For double-lip seals, confirm the dust lip faces outward.

Oversize Choices & Sleeving

-

If the crank or hub shows a groove you can feel with a fingernail, consider an oversize seal or a sleeve.

-

Sleeving combined with a standard-size seal often yields OEM-like longevity.

Crankcase Breathing

-

Excess crankcase pressure will push oil past new seals; verify breathers and separators are clear, especially on turbocharged engines.

Troubleshooting Common 4-71 Turbo Leaks (By Symptom)

For Detroit Diesel 4-71 Turbo

-

Oil Mist at Front Pulley: Front seal lip worn or hub grooved; replace seal, inspect hub, consider sleeve.

-

Oil Drip at Bell Housing: Rear main seal, flywheel housing paper, or oil pan rear corners; dye test to confirm.

-

Sooty Streaks Along Manifold: Head-to-manifold gasket leak or warped manifold; replace gaskets and true the flange.

-

Coolant Stain Along Side Rail: Water manifold gasket weeping; renew gasket and check rail straightness.

-

Persistent Weep Around Blower Base: Blower-to-block gasket compression set; install new gasket and torque evenly.

-

Fuel/Oil Cross-Contamination: Check oil cooler gaskets and core integrity before suspecting the head set.

Selecting the Right Material: Paper, Fiber, Rubber, and Composites

For Detroit Diesel 4-71 Turbo

-

Paper/Fiber Gaskets handle oil and coolant at moderate temperatures on flat faces—excellent for covers, pans, rails.

-

Molded Rubber (Rocker Cover) offers reusability and corner sealing but must match cover style (aluminum vs. stamped).

-

Metal-Faced Head Gaskets are engineered for combustion and coolant interfaces under boost—use only the correct Detroit-spec composition.

-

High-Temp Rings/Donuts (Exhaust/Turbo) withstand hot gas flow; never substitute with general paper material.

-

Sleeves & Wear Rings are not gaskets, but work hand-in-hand with seals when journals are worn.

Marine Notes for 4-71 Turbo Installations

For Detroit Diesel 4-71 Turbo

-

Raw-Water Pump Interfaces: Always replace both inlet and outlet gaskets during impeller service. Salt residue under old gaskets prevents proper seating.

-

Heat Exchanger End-Caps: Use the dedicated kit so O-ring and paper thicknesses are correct. Pressure-test before launch.

-

Turbo Riser & Marine Flanges: Match gasket ID/OD to the hardware. A mismatch restricts flow or leaves the joint under-supported, leading to soot tracks or water intrusion.

-

Bilge Cleanliness: After any gasket work, degrease the engine and bilge. A clean baseline makes future leak detection immediate.

Quick Ordering Roadmap (Follow the Catalog Order Above)

-

Start with the Overhaul Gasket Kit if you’re doing significant engine work.

-

Add crank seals (front and rear), choosing double-lip or oversize as journal condition dictates, and a sleeve if the sealing land is grooved.

-

Include front lower cover and oil pan gaskets for full reseal jobs.

-

For the top end, pair the head gasket kit with the correct rocker cover gasket (new-style aluminum or old-style stamped).

-

Reseal governor interfaces whenever removed (head-to-governor, housing-to-drive, spring cover, cap).

-

On boosted setups, don’t forget blower base/screen gaskets and head-to-manifold plus turbo riser gaskets.

-

For cooling/oiling, renew water manifold, oil cooler, thermostat housing, engine water pump cover, and (for marine) raw-water pump and heat exchanger gaskets.

-

Close with flywheel housing papers (and the Allison SAE #2 gasket if applicable), plus consumables: high-temp turbo compound, RTV (sensor-safe), non-hardening sealant, high-tack spray, threadlocker, and Detroit green paint.

Why Buy Your 4-71 Turbo Gaskets & Seals from Diesel Pro

-

Engine-Specific Fitment: The items in this section are curated for the Detroit Diesel 4-71 Turbo, with compatibility notes only where appropriate. You’re not sifting through generic catalog clutter.

-

Complete Coverage in One Stop: From overhaul kits to the smallest governor cap gasket, plus the sealants and compounds to install them correctly.

-

Quality-Focused Materials: Papers, fibers, and molded rubbers selected for Detroit two-stroke environments—oil splash, pulse exhaust, and boosted charge conditions.

-

Marine-Ready Options: Heat-exchanger kits, raw-water pump gaskets, marine flange rings, and Allison SAE #2 housing papers to support common marine packages.

-

Fast Availability: Items are stocked and ready to ship so you can keep downtime to an absolute minimum.

-

Expert Support: Need help identifying aluminum vs. stamped rocker covers or choosing between single-lip and double-lip rear seals? Get guidance before you bolt it up.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588