Parts for Detroit Diesel 671 Non-Turbo - (2 Valve Head Type) - Exhaust Section

Loading...

Loading... Parts for Detroit Diesel 6-71 Non-Turbo (2-Valve Head Type) – Exhaust Section

The Detroit Diesel 6-71 Non-Turbo (2-Valve Head Type) engine represents one of the most iconic powerplants in marine, industrial, and generator applications. Known for its reliability, rugged design, and long operational life, this inline six-cylinder two-stroke diesel engine powered vessels, heavy machinery, and stationary generators worldwide for decades. Maintaining its performance requires precise, high-quality exhaust system components—especially when operating in demanding environments where heat management, vibration, and corrosion are constant challenges.

This section provides a complete overview of the available exhaust components for the 6-71 Non-Turbo engine. Each product listed below is engineered to meet or exceed OEM specifications, ensuring excellent performance and durability. Whether your Detroit Diesel 6-71 is installed in a tugboat, fishing vessel, or industrial setup, Diesel Pro Power offers the correct marine manifold, gaskets, flanges, elbows, hoses, and accessories to keep your exhaust system in top condition.

Detroit Diesel Marine Water-Cooled Exhaust Manifold for 6-71

The marine water-cooled exhaust manifold is one of the most essential parts of the Detroit Diesel 6-71 exhaust system. It captures exhaust gases from the cylinders and directs them through a water-cooled jacket that reduces surface temperature and prevents overheating in marine engine compartments. This design ensures that the engine room remains cooler and safer, particularly in enclosed marine applications where heat dissipation is limited.

Diesel Pro Power supplies new marine manifolds designed for long-term durability under corrosive saltwater conditions. Each manifold features precision-machined flanges for a perfect seal and uses 1-inch threaded fittings to connect cooling water lines. The robust construction minimizes the risk of warping and cracking under extreme heat cycles.

Owners of Detroit Diesel 6-71 engines appreciate this manifold’s ability to maintain consistent exhaust flow while keeping operating temperatures within safe limits. When paired with genuine gaskets and fittings, it provides years of reliable service.

Head-to-Manifold Gaskets for 6-71

Proper sealing between the exhaust manifold and the cylinder head is critical to maintaining engine performance and preventing exhaust leaks. The Detroit Diesel 6-71 head-to-manifold gasket ensures an airtight connection between the manifold and cylinder head surfaces.

These gaskets are made from high-temperature-resistant composite materials that can handle extreme exhaust temperatures while maintaining flexibility for proper compression. A tight seal not only prevents harmful exhaust leaks but also ensures optimal scavenging efficiency, allowing the two-stroke 6-71 engine to maintain its characteristic power and fuel economy.

Whether used in marine or industrial setups, the gasket resists corrosion from salt air, water, and exhaust condensation. Each engine requires multiple gaskets—so referencing the engine configuration is essential when planning a full exhaust rebuild. Diesel Pro Power offers both 6-71-specific and multi-series (71 and 92) gasket options for cross-model compatibility.

Marine Exhaust Manifold Flange and Gasket Assembly

The marine exhaust manifold flange connects the manifold to the rest of the exhaust piping, serving as a structural link that allows for secure mounting and easy disassembly during maintenance. Diesel Pro Power’s replacement flange features a rugged 4-inch NPT thread, ensuring a precise connection for exhaust flow and cooling water passage.

This component is essential for marine applications because it creates a dependable transition point between the manifold and the rest of the exhaust system—whether it leads to risers, elbows, or mufflers.

Accompanying this flange is the marine exhaust manifold flange gasket, designed with a 6.25-inch outer diameter and 4.25-inch inner diameter. The gasket forms a perfect seal between the manifold flange and the adjoining exhaust components, preventing leaks that could compromise system efficiency or introduce unwanted noise.

These parts are often replaced together during a manifold service or rebuild to ensure complete sealing integrity.

Manifold Insulation Tape

In marine and industrial environments, exhaust heat management is critical for safety and performance. Manifold insulation tape provides a protective wrap around exhaust manifolds and pipes, helping to retain heat within the system while reducing the temperature of exposed surfaces.

Diesel Pro Power offers insulation tape in two sizes—3-inch and 4-inch widths—each 100 feet long and 1/8-inch thick. This high-temperature-resistant fiberglass or ceramic-based tape withstands extreme exhaust heat while maintaining flexibility for tight wrapping.

Proper insulation ensures that engine rooms remain cooler, protecting nearby wiring, hoses, and components from heat damage. It also improves engine efficiency by keeping exhaust gases hotter, which promotes smoother flow and reduces backpressure.

Manifold Mounting Hardware: Studs, Nuts, Washers, and Crabs

Reassembling the 6-71 exhaust system requires high-quality mounting hardware to maintain precise alignment and sealing. Diesel Pro Power supplies a complete range of fasteners designed specifically for Detroit Diesel engines, including studs, nuts, washers, and “crabs” (clamps) that secure the manifold in place.

The manifold stud provides the threaded connection between the cylinder head and manifold flange. Each stud is heat-treated for strength and corrosion resistance, ensuring that the manifold remains securely attached even under thermal expansion.

Complementing these are manifold nuts and washers, which distribute load evenly and prevent loosening caused by vibration. The materials used are typically zinc-coated or stainless steel to resist corrosion in humid marine environments.

The manifold crab—a specialized curved clamp—secures multiple manifold sections together, maintaining even pressure across the flanges. These components are often overlooked, but their role is crucial for ensuring that the manifold sections remain sealed and properly aligned.

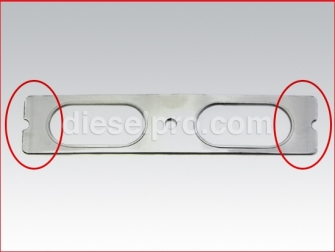

Marine Manifold Water Outlet Plate and Gasket

The marine manifold water outlet plate manages the exit point of cooling water from the exhaust manifold. Over time, this plate can corrode or warp due to constant exposure to hot saltwater. Diesel Pro Power provides replacement outlet plates made from durable corrosion-resistant metal, ensuring long-lasting performance.

Each plate uses a gasket designed for the Series 71 and 92 engines, ensuring a watertight seal and preventing leaks from the cooling jacket. This setup ensures that the water cooling system maintains optimal flow and pressure, helping protect the exhaust manifold and downstream components from heat damage.

Threaded Plates and Marine Manifold Elbows

Another critical component of the 6-71 exhaust system is the threaded plate, which provides threaded ports for connecting elbows, hoses, or sensors. Diesel Pro Power’s 3/4-inch threaded plate is precision-machined to OEM standards and designed to withstand high temperature and pressure.

To route exhaust gases efficiently, marine manifold elbows are used to change the direction of flow within tight engine room configurations. The 90-degree and 45-degree elbows offered by Diesel Pro Power come in multiple thread sizes—3/4-inch and 1-inch—to accommodate different setups.

These elbows are typically made from brass or cast bronze, materials known for their corrosion resistance and thermal durability in marine applications. They allow for flexible installation layouts while maintaining smooth exhaust gas flow and preventing backpressure.

Industrial Exhaust Flange, Gasket, and Muffler Assemblies

While many Detroit Diesel 6-71 engines operate in marine settings, thousands more serve in industrial power generation, pumping, and stationary applications. For these configurations, Diesel Pro Power supplies a range of industrial exhaust flanges, gaskets, and mufflers designed to withstand continuous operation in high-heat environments.

The industrial exhaust flange features a 4-inch internal diameter for connection to standard exhaust piping. The matching gasket ensures leak-free operation between the flange and pipe joint.

To control noise and backpressure, the industrial muffler provides efficient sound attenuation with 4-inch NPT inlet and outlet connections. The muffler is engineered to handle the high-flow exhaust output of the 6-71 engine while reducing noise to acceptable industrial levels. Its construction resists rust and vibration, ensuring long service life in demanding installations.

Muffler Caps and Exhaust Outlet Protection

Marine and stationary engines are often exposed to weather elements, and preventing moisture entry into the exhaust system is critical. Diesel Pro Power offers muffler caps in several sizes—3-inch, 3.5-inch, 4.5-inch, and 5-inch—to fit various exhaust outlet diameters.

These caps automatically close when the engine is off, blocking rain, debris, and seawater from entering the exhaust system. Constructed from stainless or galvanized steel, they offer superior corrosion resistance and smooth operation.

Installing muffler caps helps extend the life of exhaust components and prevents hydrostatic lock—a potentially catastrophic condition caused by water entering the cylinders through the exhaust system.

Flexible Metal Exhaust Hose

Engines like the Detroit Diesel 6-71 produce vibration and movement that can stress rigid exhaust components. The flexible metal exhaust hose absorbs vibration and allows for thermal expansion while maintaining a secure exhaust flow path.

Diesel Pro Power’s flexible hose, available in 4-inch diameter and 18-inch length, is designed for both marine and industrial use. It is reinforced with interlocking metal layers that can handle high exhaust temperatures and pressure while resisting cracking and fatigue.

This flexibility ensures that exhaust connections remain leak-free and reduces the likelihood of exhaust system fatigue or damage caused by engine movement.

Temperature Switch

Monitoring exhaust and engine temperature is vital to prevent overheating and maintain safe operation. The temperature switch offered by Diesel Pro Power activates at 205°F and fits 1/2-inch NPT threads. It can be used for both Detroit Diesel and other engines like Cummins or Caterpillar.

This switch ensures early detection of overheating, providing an essential layer of protection for the 6-71’s exhaust system and cooling components. It is often installed near the manifold or water outlet to monitor thermal conditions.

Detroit Diesel Green Paint

After completing an exhaust system service or rebuild, finishing the installation with authentic Detroit Diesel green engine paint provides both corrosion protection and a professional appearance. Diesel Pro Power offers this paint in the exact Detroit factory shade, making it ideal for restoration or aesthetic touch-ups.

The high-temperature formulation resists heat and oil contamination, keeping the engine compartment clean and consistent with OEM presentation.

Gauges and Monitoring Equipment

Maintaining proper engine monitoring is essential for long-term reliability. Diesel Pro Power provides a complete range of mechanical and electrical gauges compatible with Detroit Diesel 6-71 engines. These include mechanical gauges with alarm functions and electric versions in both 12V and 24V configurations.

Accurate readings of temperature, pressure, and other vital parameters allow operators to detect issues early and prevent costly repairs.

Why Buy Detroit Diesel 6-71 Non-Turbo Exhaust Parts from Diesel Pro Power

Diesel Pro Power has supplied genuine and replacement Detroit Diesel parts to over 40,000 satisfied customers worldwide. Our reputation is built on reliability, precision, and expert support for classic engines like the 6-71.

Unmatched Quality and Compatibility

Every exhaust component sold through Diesel Pro Power is manufactured or rebuilt to meet OEM-level specifications. From marine manifolds to flanges and gaskets, each part is designed for perfect fitment and long-term durability.

Fast Global Shipping and Real-Time Tracking

Diesel Pro Power understands that downtime costs money. We maintain one of the largest inventories of Detroit Diesel parts in the world and offer fast international shipping with real-time tracking. Whether your 6-71 powers a commercial fishing boat in Alaska or a generator in the Caribbean, your parts will arrive quickly and securely.

Expert Technical Assistance

Our technical team specializes in legacy Detroit Diesel engines. We provide expert advice on installation, compatibility, and troubleshooting, ensuring that customers receive the right part the first time.

Marine and Industrial Expertise

Diesel Pro Power supports both marine and industrial Detroit Diesel users. We supply corrosion-resistant components for marine vessels and heavy-duty fittings for industrial engines, providing a single reliable source for all exhaust-related needs.

Proven Performance You Can Trust

For decades, the Detroit Diesel 6-71 has been an icon of durability. Keeping these engines running efficiently requires high-quality replacement components. Diesel Pro Power ensures every part—from gaskets and manifolds to elbows and insulation—is tested for reliability and precision.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588