Parts for Detroit Diesel 671 Non-Turbo - (2 Valve Head Type) - Gasket Section

Loading...

Loading... Parts for Detroit Diesel 6-71 Non-Turbo (2-Valve Head Type) — Gasket Section

Welcome to the dedicated gasket and sealing resource for the Detroit Diesel 6-71 non-turbo, 2-valve head configuration (mechanical blower, no turbocharger). This page is written specifically for mechanics, operators, and rebuilders working on the classic inline-six 71-series platform. While some components below are physically interchangeable across other 71-series or V-71 engines, the focus here is squarely on the 6-71 two-valve head type so you can select confidently and complete jobs without comeback.

Below you’ll find an expanded guide to every major gasket and sealing category represented in the catalog you pasted—organized for real-world troubleshooting and rebuild workflows. We’ll explain where each gasket lives, why it fails, how to pick the correct style (old vs. new rocker cover, single- vs. double-lip crank seals, standard vs. oversize rear main with sleeve), and proven tips for prep, install, and verification on the 6-71. We’ll also include notes about marine cooling hardware (raw water pump and heat exchanger gasket kits) often paired with 6-71 marine builds, plus Allison marine gear interface gaskets where applicable.

For Detroit Diesel 6-71 Non-Turbo — Complete Engine Gasket Coverage

Gaskets for Complete Overhauls (Top-End & Lower-End)

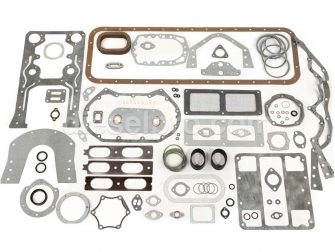

Overhaul Gasket Kits (Full Engine Sets)

A comprehensive engine overhaul set is the fastest way to ensure you have all paper, rubber, and composite seals needed for both top-end and bottom-end reassembly on the 6-71. A well-composed kit typically includes:

-

Cylinder head gaskets and upper engine seals (rocker cover, thermostat housing, coolant crossover/water manifold, governor body interfaces).

-

Intake, blower, and exhaust interface gaskets (including blower-to-block and blower cover interfaces).

-

Oil system gaskets (oil cooler, oil filter adaptor, oil pan).

-

Front and rear cover gaskets, front lower cover, and accessory mounting gaskets.

-

Common service consumables such as inspection cover gaskets and small ancillary seals.

When to choose a full overhaul kit:

-

After a spun bearing, coolant-in-oil event, detonation/piston failure, or when liner protrusion measurements require block counterbore work.

-

During a full in-frame or out-of-frame rebuild to eliminate mismatch between materials and thicknesses.

-

To reduce reassembly delays from missing “small” gaskets (governor covers, screens, plates) that are easy to overlook.

Head Gasket Kits (Upper Engine Sets)

A dedicated head set focuses on the top end. This is helpful for valve jobs, top-end refreshes, and in situations where compression loss is traced to head gasket leakage. On the 2-valve head 6-71, be mindful of:

-

Correct head gasket fire-ring configuration for the 2-valve head architecture.

-

Included rocker cover gaskets (old-style tin vs. new-style aluminum cover), plus stem seals and related top-end interfaces.

-

Thermostat housing and coolant crossover/water manifold gaskets that are commonly disturbed during head service.

Pro tip: Before ordering a head set, confirm you truly have 2-valve heads (two valves per cylinder) and not a later 4-valve conversion. The castings, coolant passages, and rocker gear tooling differ—choosing the wrong set risks misalignment and coolant/oil cross-leaks.

Gaskets for the Front & Rear of Engine (Crankshaft & Covers)

Front Main (Crankshaft) Seal — Standard, Universal Rotation

On a mechanically blown, non-turbo 6-71, a proper front main seal protects against oil sling behind the accessory drive and harmonic balancer. Look for:

-

“Standard” size seal if your crank snout and cover bore are within factory spec.

-

Universal rotation compatibility matters on Detroit two-strokes with accessory drives that can be installed for either rotation mode. Using a universal-rotation front seal eliminates guesswork.

Rear Main (Crankshaft) Seal — Single-Lip / Double-Lip; Standard / Oversize

Rear main leakage is one of the most common customer complaints. You’ll encounter:

-

Single-lip variants for normal duty and double-lip designs for added contamination control and stability.

-

Standard or oversize diameters. Oversize is selected when the crank’s seal surface has worn a groove. In those cases, pair the oversize seal with the rear seal sleeve to restore proper running surface.

Rear Seal Sleeve (Oversize Applications)

When a groove is worn into the crank sealing land, an oversize rear main plus a sleeve brings the surface back to spec. Properly prepping this sleeve—polishing the crank, cleaning, aligning, and pressing square—is critical to prevent eccentric seal wear and renewed leaks within 50–200 hours.

Front Lower Cover & Front Cover Gaskets

These gaskets live behind pulleys and drives and are often ignored until there’s a slow, annoying oil drip. If the cover has ever been pried off without alignment pins, warpage can occur; straight-edge the cover and dress high spots before reassembly.

Inspection Cover Gaskets

The 6-71 block inspection cover(s) use thin paper/composite gaskets that go brittle and weep. Any time you open the cover for timing checks or internal inspection, replace the gasket with fresh material and clean surfaces thoroughly.

Gaskets for Cylinder Head, Rocker Cover & Valve Train (2-Valve Head)

Rocker Cover Gaskets — Old-Style Tin vs. New-Style Aluminum

The 6-71 saw two predominant rocker cover styles:

-

Old-style tin (stamped steel) covers use a black rubber profile gasket.

-

New-style aluminum covers use a gray rubber gasket or a kit with retainer hardware.

Identify your cover before ordering. Mixing styles can lead to seepage around the perimeter, especially after heat cycles.

Governor-to-Head & Governor Drive Gaskets

The governor assembly interfaces to the head and blower cover with thin paper gaskets. Minor seepage here becomes a grime magnet. Always de-oil both faces, note any pitting on the casting ears, and use a moderate film of non-hardening sealant only if the service manual calls for it (over-sealing can block oil drillings).

Thermostat & Thermostat Housing Gaskets

Any time you pull the housing to change thermostats, install new thermostat and housing gaskets. Inspect for erosion at the housing neck—if the sealing land is scalloped, even a new gasket may not hold. Light dressing is acceptable; severe pitting requires replacement.

Water Rail / Manifold Gaskets

The long water rail along the head face is prone to seepage if the rail bows. Use a straight-edge; if it’s out of true, correct it before fitting the new gasket. Always torque in sequence to avoid stressing the new seal.

Gaskets for Exhaust Manifold & Blower Interfaces

Head-to-Manifold Exhaust Gaskets

Exhaust leaks risk valve burning and hot spots at the head flange. For the 6-71 two-valve:

-

Verify the correct port shape gasket for your manifold (there are pattern differences across the 71 family).

-

Replace all head-to-manifold gaskets together—even if only one port was leaking—to keep flange tension even and prevent future leaks.

-

Retorque after the initial heat cycle if procedures permit.

Marine Manifold Flange Gaskets (Where Equipped)

On marine-equipped 6-71 engines using water-jacketed manifolds or elbows, ensure the flange gasket matches the OD/ID of your flange to avoid blow-by or flow restriction. If you see salt creep at the joint, check for warpage and correct before sealing.

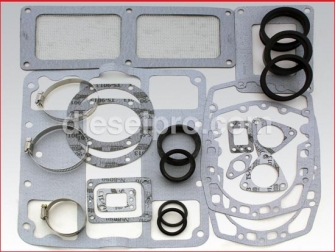

Blower-Related Gaskets

Because every Detroit two-stroke uses a Roots-type blower for scavenging, blower sealing is critical to idle quality and oil control:

-

Blower-to-block gasket: This is the base interface; any air leak here will affect crankcase pressure and scavenging.

-

Blower screen gasket: Goes with the screen that prevents debris from entering the blower intake—replace when disturbed.

-

End-plate and striker-plate gaskets: Specific to older blower styles—important for sealing gear housings and end covers.

-

Governor drive gasket at blower cover: Seals the governor drive stub to the blower housing; replace whenever the drive is removed.

Pro tip: After blower service, always check for shaft endplay, gear backlash, and ensure the rotor timing is correct. A perfectly sealed blower with incorrect timing can still yield low power and high EGT.

Gaskets for Oil System (Oil Pan, Oil Cooler, Filter Adaptor)

Oil Pan Gasket

The 6-71 oil pan uses a formed gasket that should be replaced any time the pan drops for bearing inspection or sludge cleaning. Inspect the pan rail for dents from over-tightening. Use a torque wrench and even pattern—hand “feel” often warps the rail.

Oil Cooler Gaskets (Two Common Styles)

You’ll encounter more than one oil cooler gasket design around the 6-71. Match the core style and face pattern. If you’re diagnosing cross-contamination, pressure-test the cooler core off-engine. New gaskets won’t solve a pinholed core.

Oil Filter Adaptor Gasket

A small leak at the filter adaptor can coat the side of the block over time. Clean both faces thoroughly. If the adaptor O-ring/gasket has taken a set, replace it rather than “doubling up”—stacked gaskets often leak.

Gaskets for Cooling System (Engine & Marine)

Freshwater (Engine) Water Pump & Cover Gaskets

When replacing the engine-driven water pump, always renew the pump cover gasket and any accessory mounting gaskets. Cavitation or corrosion at the cover is common—lightly dress the sealing land and check shaft seal condition.

Thermostat & Housing (recap)

Pair the thermostat face gasket with a fresh housing gasket. Replace corroded fasteners; inconsistent clamp load is a silent leak source.

Raw Water (Marine) Pump Gaskets & Mounting Gaskets

On marine 6-71 packages, the raw water pump uses small inlet/outlet paper gaskets—most pumps require two (one for the inlet and one for the outlet). There is also a mounting gasket between the pump and its bracket or mating pad. Replace all disturbed gaskets during impeller service to stop drips that only appear at running RPM.

Heat Exchanger Gasket Kits (Marine)

A proper kit bundles end-cap gaskets, covers, and plate gaskets for the marine heat exchanger. While this catalog supports multiple Detroit families, for your 6-71 marine build ensure the kit layout matches your exchanger length and cap style. Pressure test the bundle after reassembly and confirm no weeping at end caps after the first hot run.

Gaskets for Fuel & Accessory Drives

Fuel Pump / Water Pump Combo Gaskets

Where the fuel and water pump share a mounting surface or bracket, there’s a combo gasket. Replace it any time either pump is serviced. Always check for flange pitting and address with light dressing to avoid wedge leaks.

Starter Gasket

The starter adapter on many Detroit installations uses a thin gasket. While it’s not an oil pressure joint, it helps keep grime, oil mist, and salt spray out of the interface. Replace on removal—reusing compressed paper gaskets here typically leads to wicking.

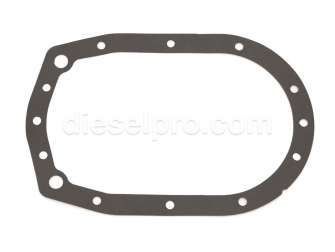

Gaskets for Flywheel Housing, Transmission & Marine Gear

Flywheel Housing Gasket (Engine-to-Housing)

Seals the flywheel housing to the rear of the block. If you find leaks that seem like rear main seal failures, inspect the flywheel housing gasket carefully; oil can track around the perimeter and drip at the lowest point, mimicking a rear seal leak.

Flywheel Housing Covers (Large & Small Plates)

Service plates on the flywheel housing require their own cover gaskets. Any time you open these for alignment checks or ring-gear inspection, replace the gasket and verify plate flatness.

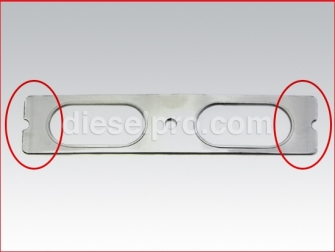

Allison Marine Gear Interface — Flywheel Housing to Transmission (SAE #2)

Many marine 6-71 packages couple to an Allison M or MH marine transmission. The SAE #2 housing-to-transmission gasket is installed between matching SAE #2 housings. Use it whenever the gear is removed for damper, oil seal, or flex plate service. Proper alignment and cleanliness are vital to prevent coupling fretting and oil misting at this high-load interface.

Exhaust, Insulation & Finishing Consumables

Manifold Insulation Tape (Exhaust Wrap)

Useful for managing radiant heat near hoses and wiring. When re-wrapping, overlap consistently and avoid trapping oils under the wrap. Replace broken wrap after manifold service—burnt wrap sheds fibers and can retain corrosive moisture.

Detroit Green Engine Paint

After gasketed joints are sealed and torqued, repainting cleaned areas with Detroit green helps spot new seeps quickly. Only paint after leak checks—never use paint to “hide” wet joints.

Governor & Small-Format Gaskets

Hydraulic Governor Gaskets (Body & Cover)

The hydraulic governor interfaces include small body and cover gaskets that often seep. Replace them during any calibration or inspection. Confirm free motion of springs and weights; trapped debris can scar gasket faces, creating persistent weeps.

Governor Spring Cover & Housing Cap Gaskets

These thin seals are easy to damage during removal. Replace rather than reuse. Lightly oil paper gaskets unless the service manual specifies dry install or a specific sealant.

Adapters, Plates & “Utility” Gaskets

Adapter & Plate Gaskets (Cooling and Marine Pump Plates)

Adapter and plate gaskets (for marine raw water pumps and various accessory plates) are critical to maintain suction on the raw water side and to keep oil and coolant separated on the engine side. Replace any plate that’s warped more than a few thousandths; no gasket can compensate for a bowed plate long-term.

General-Purpose 71-Series Utility Gaskets

Some gaskets are listed as suitable across 53/71/92 families. For the 6-71 two-valve, use them only where the mating geometry is known to be identical (inspection covers, certain small plates). For head, exhaust, and blower interfaces, always pick the 6-71-specific pattern.

Sealants, Sprays & Thread Treatments (Shop Essentials)

High-Tack Gasket Spray

Excellent for thin paper gaskets that need temporary adhesion during assembly (inspection covers, governor housings). Use sparingly—more is not better. Avoid overspray into oil galleries and coolant passages.

Non-Hardening Pliable Sealant

Ideal where you may need to re-index a part during assembly, or on fasteners that penetrate wet cavities. Remains flexible, resisting vibration-induced weeping.

Silicone RTV (Sensor-Safe, Ultra Blue, High-Temp)

Use silicone RTV only where specified, such as timing or inspection cover corners, and avoid over-application that could extrude into oil/coolant paths. Sensor-safe formulas protect nearby senders and harnesses. High-temp RTV is useful near exhaust interfaces—never substitute RTV for a missing exhaust gasket.

Threadlocker (High-Strength Red)

Essential on rotating assembly fasteners and hardware that experiences cyclic vibration. Degrease threads fully before application; oil contamination deactivates threadlocker.

3H-Style Gasket Maker & Cold Weld Epoxy

-

Gasket makers can fill minor surface imperfections but should not be used to compensate for major warpage or to replace a proper formed gasket.

-

Cold weld epoxies are for minor casting repairs away from high-temperature, high-pressure zones; follow cure schedules exactly.

For Detroit Diesel 6-71 Non-Turbo — Selection & Installation Tips

Confirm 2-Valve Head Architecture

-

Two valves per cylinder. If you see four valves per cylinder, you’re on a 4-valve conversion and will need a different head set and possibly different exhaust port gaskets.

-

Check rocker cover style (old tin vs. new aluminum) and match the gasket accordingly.

Standard vs. Oversize Rear Main Seals

-

Inspect the crank sealing surface. If there’s a distinct groove or measurable wear, select oversize + sleeve.

-

Use proper sleeve drivers, align perfectly, and verify run-out. A cocked sleeve ruins new seals in hours.

Single-Lip vs. Double-Lip Rear Main

-

Use double-lip for harsher environments (marine bilges, dusty plants) or when you want extra margin on a high-hour crank surface.

-

Single-lip is acceptable on fresh surfaces where contamination ingress is controlled.

Surface Prep

-

Scrape with plastic or brass tools, never gouge aluminum or cast iron sealing lands.

-

Brake-clean residue, then wipe dry; a film of oil under paper gaskets leads to early creep and seepage.

Torque & Sequence

-

Follow factory torque values and patterns—especially on head, exhaust manifold, and water rail fasteners.

-

Re-torque after the first full heat cycle if the procedure and fastener type call for it. Not all Detroit fasteners are re-torque items; check your manual.

Leak Verification

-

After first run, use a bright light to inspect: front lower cover corners, rear main dust lip area, oil cooler faces, head-to-manifold ports, water rail joints, and raw water pump in/outlet flanges.

-

Wipe clean, then re-check after a short sea trial or road test.

Common Failure Clues

-

Oil on flywheel housing weep hole: Rear main or flywheel housing perimeter gasket.

-

Coolant tracking down block from head line: Water rail or thermostat housing interface.

-

Soot lines at exhaust ports: Head-to-manifold gasket leakage or warped manifold flange.

-

Oil haze around blower base: Blower-to-block gasket or screen gasket compromised; check crankcase pressure.

For Detroit Diesel 6-71 Non-Turbo — Marine Notes (If Applicable)

Many 6-71 engines live in marine service. If you’re maintaining a marine 6-71:

-

Replace both raw water pump gaskets (inlet and outlet) during impeller changes and use the mounting gasket to prevent suction loss.

-

Use the heat exchanger gasket kit matched to your cooler length and cap style; verify cap fit and O-ring/gasket compression.

-

If coupled to an Allison M or MH gear through an SAE #2 interface, install a fresh flywheel housing-to-transmission gasket during alignment checks or gear removal.

For Detroit Diesel 6-71 Non-Turbo — Troubleshooting by Symptom

-

Persistent oil drip at bellhousing: Dye-trace to differentiate between rear main and flywheel housing perimeter gasket. If the crank land is grooved, move to oversize + sleeve.

-

Coolant smell, but no visible puddles: Check thermostat housing and water rail joints first; minor creep evaporates on a hot block.

-

Unstable idle after blower service: Recheck blower-to-block gasket seating, verify rotor timing, and inspect governor drive gasket surfaces.

-

Sooting at engine room bulkhead: Look for head-to-manifold gasket blow-by; replace the set across all ports and check manifold flatness.

-

Milky oil (marine): Pressure-test the oil cooler and inspect heat exchanger inter-coolant interfaces; new gaskets won’t cure a perforated core.

Why Buy 6-71 Gaskets from Diesel Pro Power

Choosing the right gasket is only half of a successful repair—the other half is getting the right parts on time from a supplier that truly knows Detroit two-strokes.

-

Purpose-Built Catalog for the 6-71 (2-Valve Non-Turbo): This guide and the linked products are curated specifically around the 6-71 two-valve architecture to reduce mis-orders and downtime.

-

Exact-Fit Components: From old-style tin to new-style aluminum rocker cover gaskets, from standard to oversize rear mains with sleeves, the coverage you see here matches what seasoned Detroit mechanics actually use.

-

Marine-Ready Options: If your 6-71 lives on the water, you’ll find the raw water pump, heat exchanger, and SAE #2 gear interface gaskets needed to complete a bilge-clean, reliable install.

-

Pro-grade Sealants & Supplies: High-tack sprays, sensor-safe RTV, non-hardening sealants, threadlocker, and finishing Detroit green paint—everything to finish the job correctly.

-

Fast Shipping & Real Support: Parts are clearly marked In Stock, and our support team knows these engines.

-

Trusted by 40,000+ satisfied customers: Professional fleets, yards, and owner-operators rely on Diesel Pro Power for consistent quality and knowledgeable help.

For Detroit Diesel 6-71 Non-Turbo — Quick Reference (What to Check Before You Order)

-

Verify 2-valve cylinder head configuration.

-

Identify rocker cover style (old tin vs. new aluminum).

-

Inspect crank seal lands (choose standard vs. oversize; sleeve if grooved).

-

Note whether the engine is in marine service (raw water pump gaskets, heat exchanger kit, SAE #2 gear interface).

-

Check manifold flatness if you saw any soot trails at ports.

-

Plan to replace all disturbed gaskets during service—don’t reuse compressed paper seals.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588