Parts for Detroit Diesel 671 Non-Turbo - (4 Valve Head Type) - Blower Section

Loading...

Loading... -

Detroit Diesel 6-71 Blower, Supercharger - Rebuilt

BLOW 6-71 LH

Blower mounde on Left Side of engine. Sold with refundable core deposit. See details

Price: $ 1,658.87 -

Detroit Diesel 6-71 Blower, Supercharger - Rebuilt

BLOW 6-71 RH

Blower mounted on Right Side of engine. Sold with refundable core deposit . See details

Price: $ 1,658.87 -

-

-

-

-

-

-

-

Hub for the blower shaft to drive Aluminum Hydraulic pump

5127670

For in line 71 series enginesPrice: $ 389.50 -

-

-

-

-

-

-

-

-

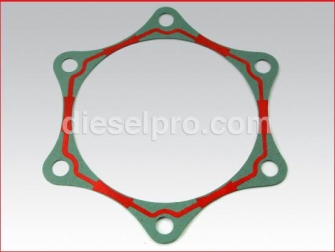

Detroit Diesel Governor drive Gasket

5150246

Gasket between blower cover and Governor drive

Price: $ 5.30 -

Detroit Diesel Governor Gasket

5150890

Gasket between the governor housing and the governor drive

Price: $ 3.52 -

-

-

-

-

Detroit Diesel Blower drive cover hose for engine 3-71, 4-71 and 6-71

5172865

2 3/4" x .95"

Price: $ 8.13 -

-

-

-

Detroit Diesel Gasket for Hydraulic Governor

23509675

Gasket between Governor and DrivePrice: $ 5.50 -

-

-

Teleflex Morse Ball joint type terminal for 1/4" marine cable

29104

For 43C Teleflex-morse marine cables

Price: $ 29.83 -

Teleflex Morse Clevis type terminal for 1/4" marine cable

29025

For 43C Teleflex-morse marine cables

Price: $ 35.50 -

Green Paint for Detroit Diesel Engines

26006

Available for ground shipping only in USA and CanadaPrice: $ 12.46 -

Gasket Spray -High Tack Sealant (Hold & Seals Cut Gaskets)

99MA

For Detroit Diesel & Cummins engines. Available for ground shipping only in USA and CanadaPrice: $ 20.55 -

Parts for Detroit Diesel 6-71 Non-Turbo (4-Valve Head) – Blower Section

The Detroit Diesel 6-71 (four-valve head) is a cornerstone of the Series 71 two-stroke family. On these engines, the Roots-type blower isn’t just an add-on—it’s the heartbeat of the air system, scavenging exhaust and packing fresh air for every power stroke. This section brings together the rebuilt blowers plus every seal, gasket, shaft, and accessory you need to service the blower drive on in-line 6-71 applications (including marine setups with Allison gears).

Rebuilt 6-71 Blowers (Left-Hand & Right-Hand)

Two orientations are common on the 6-71:

-

Left-Hand (LH) Mount – Blower mounted on the left side of the engine when viewed from the flywheel.

-

Right-Hand (RH) Mount – Blower mounted on the right side of the engine.

Each rebuilt unit is fully disassembled, cleaned, inspected, and fitted with new bearings, seals, and gaskets. Rotor timing and clearances are set to factory spec so you get stable idle, crisp throttle response, and strong scavenging under load. Units are sold with a refundable core deposit for cost savings and sustainability.

When to choose LH vs. RH: match the orientation your engine/installation was built with—this keeps your governor, intake ducting, and accessory drives aligned without modifications.

Blower Repair & Installation Kits

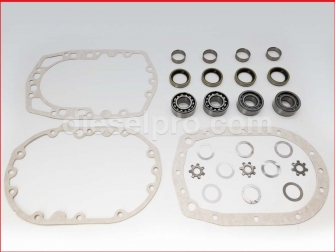

Blower Repair Kit (Series 71 – Natural)

A complete internal refresh for serviceable units. Typical contents include rotor endplate gaskets, oil seals, bearings, and the small parts needed to restore airtight integrity and quiet operation.

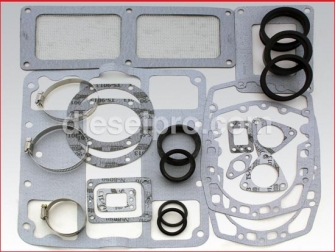

Blower Installation Gasket Kit (6-71)

Correct, uniform sealing thickness is critical on two-stroke Detroits. This kit includes the blower-to-block and cover gaskets needed to seat the rebuilt blower, prevent unmetered air leaks, and keep oil where it belongs.

Couplings, Shafts & Drive Hardware

Blower Coupling (Thin 48-Spline)

The coupling links the accessory/gear drive to the blower input. Precision-machined for the thin 48-spline interface, it transmits torque without chatter, protecting the blower gears and front bearings.

Blower Shafts for 6-71

Multiple lengths support different accessory/front cover arrangements:

-

12.125" 48-spline shaft – Common on in-line 6-71 configurations.

-

11.06" 48-spline shaft – For shorter stackups or specific front covers.

-

12.00" 48-spline shaft (Marine with Allison gear) – Sized for marine installations using Allison transmissions.

Use the length that matches your housing, hub stack, and front cover depth. Replacing a worn shaft with the correct length minimizes spline wear and maintains blower timing.

Blower Shaft Retainer

Locks the shaft axially so spline engagement stays consistent over thousands of hours.

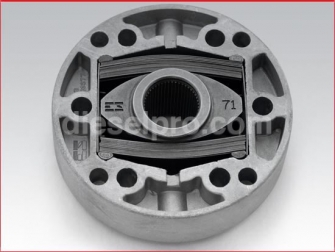

Accessory Drive/Hub Components

-

Aluminum hydraulic pump drive hub (in-line 71) – Couples the blower shaft to an auxiliary hydraulic pump on marine/industrial rigs.

-

Hub for Blower Rotor Gear – Maintains precise gear fit and rotor timing; critical for quiet operation and minimal backflow.

Lubrication & Oil Supply Tubes

-

Tube to lubricate blower drive bearing – Feeds oil to the blower drive so bearings live long at sustained RPM.

-

Oil supply tube for governor drive – Ensures the governor drive receives steady lubrication, stabilizing speed control and idle quality.

Pro tip: replace hard or flattened tube seals whenever the blower or governor drive is removed—small leaks here can cause big messes and unstable operation.

Gaskets for a Leak-Free Airbox

Airtight sealing preserves blower efficiency. This section covers the most used 6-71 gaskets:

-

Blower drive gear cover gasket – Seals the gear cavity.

-

Blower screen gasket (6-71) – Seats the inlet screen, keeping debris out of the rotors.

-

Blower & striker plate gasket (6-71) – Correct sealing at the striker plate prevents air bypass.

-

Blower-to-block gasket (6-71) – Primary seal between airbox and blower; critical on 4-valve heads.

-

End plate gaskets (old-style blowers) – Refresh these during any endplate service.

-

Governor drive gasket / governor gasket / spring-cover gasket / housing cap gasket – Keep oil in the governor and air out; small parts with big impact on drivability.

Seals, Sleeves & Drive Cover Hose

-

Blower oil seals (Series 71) – Keep oil out of the air stream; replace anytime the blower is open.

-

Seal sleeves (Series 71/92) – Renew the sealing surface; vital if the original shaft surface is grooved.

-

Blower drive cover hose (2.75" × ~0.95") – The molded hose for the drive cover—aged rubber here is a common source of weeping and mess.

Air Intake & Silencer Options

-

Industrial Air Cleaner (4" inlet) – High-dust environments demand reliable filtration to protect rotor tips and end plates from abrasive wear.

-

Marine Silencer (6-71) – Cuts intake roar without choking airflow—perfect for enclosed engine rooms where comfort and communication matter.

Tip: verify inlet diameter and body height/diameter against your cowl, hatch, or guard for painless fitment.

Air Box Breather Valve & Governor Interface

-

Air Box Breather Valve Assembly – Controls crankcase ventilation into the airbox to reduce oil carry-over and maintain clean, dry intake charge.

-

Hydraulic Governor Gasket – The thin interface gasket between the governor and its drive; a fresh seal prevents oil migration and wandering idle.

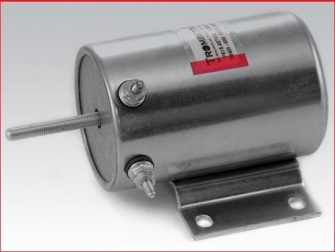

Electrical Shutdown Control

-

Shutdown Solenoid – 12V and Shutdown Solenoid – 24/32V

These fail-safe devices cut fuel for routine shutdowns and emergencies. Choose voltage to match your vessel/vehicle bus. A crisp, reliable shutdown protects engines and gearboxes alike.

Control Cable Terminals (Marine)

-

Teleflex/Morse 43C Ball-Joint Terminal (¼") – Swiveling end for smooth geometry on throttle/governor linkages.

-

Teleflex/Morse 43C Clevis Terminal (¼") – Positive, lash-free connection where a rigid pin joint is preferred.

Stainless construction resists corrosion; always replace frayed or loose ends—slop in the linkage becomes surging at the dock.

Appearance & Assembly Aids

-

Detroit Green Engine Paint – The classic finish that also helps spot fresh leaks after service.

-

High-Tack Gasket Spray – Improves adhesion of paper/composite gaskets around the blower, airbox, and covers; especially helpful on older, slightly pitted surfaces.

Why Buy From Diesel Pro Power

Proven Quality, Perfect Fit

Every rebuilt blower, shaft, coupling, gasket, and seal is curated for the 6-71 four-valve platform and checked to meet or exceed factory specifications. The result: easy installs, stable rotor timing, and long service life.

Experts on Classic Detroits

From choosing the correct LH/RH blower to confirming shaft length for marine Allison gear covers, our team knows these engines inside and out and can help you avoid costly rework.

Fast Global Shipping

We ship to 180 countries and support fleets, shipyards, and shops worldwide—so your 6-71 is back online sooner.

Trusted by 40,000+ Customers

Decades of focused Detroit Diesel experience means you get the right parts, first time—supported by clear documentation and responsive help.

One Supplier, Complete Blower Coverage

Rebuilt blowers, install kits, drive hardware, air cleaners, silencers, solenoids, governor gaskets—everything for the blower system in one place.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588