Parts for Detroit Diesel 671 Non-Turbo - (4 Valve Head Type) - Cylinder head Section

Loading...

Loading... -

Detroit Diesel cylinder head for 6-71, 12V71

5102770B12

Rebuilt - bare. Sold with refundable core deposit. See details.Price: $ 1,986.54 -

-

Detroit Diesel cylinder head for 671, 12V71

5102770V12

NEW - with valves and springs. (U) and springs. With U valves for natural and turbo enginesPrice: $ 4,714.12 -

Detroit Diesel cylinder head for 671, 12V71

5102770C

NEW - with all components and J6 valves for hi performance turbo enginesPrice: $ 8,336.82 -

-

-

-

-

-

-

-

-

Detroit Diesel valve cover, 671, 12V71

U5103800

With oil filler and breatherUsed, inspected, sandblasted and painted with primer

Price: $ 236.50 -

-

Detroit Diesel valve cover, 671, 12V71

U5103744

Used, inspected, sandblasted and painted with primerPrice: $ 220.90 -

-

-

Detroit Diesel Rocker cover kit for 6-71, 12V71

5149512

For use with aluminum rocker covers. New stylePrice: $ 115.28 -

-

-

-

-

Detroit Diesel Rocker cover gasket for 6-71 and 12V71

5143407

For tin cover, old style - black rubber

Price: $ 22.64 -

-

-

-

-

-

-

Regulator Screw - Valve Bridge for Detroit Diesel Engines

5129101

Precision-threaded — for valve bridge; fits Detroit Diesel 71 & 92 Series.Price: $ 8.88 -

-

Kent Moore flaring die for Detroit injector tube installation

J-5286-6

This flaring die is part of an injector tube reconditioning kit.Price: $ 191.25 -

-

-

-

Spring, Push Rod for Detroit Diesel 53, 71 & 92 series engines

5186858

2 5/8" Free Length, .177" Wire Dia., 11 Coils, R.H. HelixPrice: $ 9.03 -

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

Detroit Diesel Fuel Line (Short) for Series 71 and 92

5111526

Short. Each engine uses short and long fuel lines

Price: $ 11.37 -

Detroit Diesel Fuel Line (Long) for Series 71 and 92

5111527

Long. Each engine uses short and long fuel lines

Price: $ 11.97 -

Socket To Install & Remove Injector Fuel Lines For Detroit Diesel 53, 71, 92

J8932B

.Price: $ 154.53 -

Detroit Diesel Elbow

8924161

45 degree Inverted flare elbow - with no restriction - 1/4 X 3/8

Price: $ 22.48 -

Detroit Diesel Suction Elbow for Engine

8924155

Fuel pump 90 degree Inverted flare elbow - with no restriction - 3/8 x 1/2

Price: $ 20.28 -

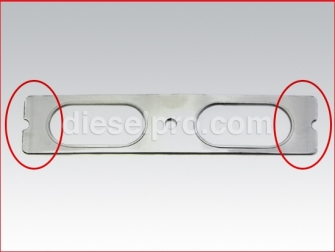

Detroit Diesel Head to Manifold Gasket for 6-71 and 12V71

5120223

Click on + Pictures below to see how many are needed per engine

Price: $ 10.78 -

Detroit Diesel Head to Manifold Gasket for 471, 671, 8V71, 12V71, 16V71, 8V92, 16V92

5120224

Click on + Pictures below to see how many are needed per engine

Price: $ 13.74 -

-

-

-

Temperature switch for Detroit Diesel, Cummins, Caterpillar engines

5146080

Closes at 205 degrees Fahrenheit.Thread size is 1/2 NPTPrice: $ 97.19 -

Green Paint for Detroit Diesel Engines

26006

Available for ground shipping only in USA and CanadaPrice: $ 12.46 -

-

Detroit Diesel 6-71 Non-Turbo Cylinder Head and Related Components

The Detroit Diesel 6-71 non-turbo engine is one of the most iconic members of the Series 71 two-stroke family. Designed for reliability in marine, industrial, and generator applications, the 6-71 has been powering vessels, equipment, and stationary installations for decades. At the heart of its performance is the cylinder head assembly—a critical component that ensures efficient combustion, proper airflow, and long-term durability.

This catalog provides a complete selection of cylinder heads and related components for the 6-71 non-turbo, offering everything from bare rebuilt heads to fully assembled units, as well as gaskets, valves, valve train parts, and installation hardware. Whether you are performing a top-end rebuild, replacing a damaged head, or stocking spares for preventive maintenance, Diesel Pro Power delivers all the essential parts in one place.

Cylinder Heads for Detroit Diesel 6-71 Non-Turbo

Rebuilt Bare Cylinder Head

A rebuilt bare cylinder head for the 6-71 engine provides a cost-effective solution for operators looking to restore performance without investing in a brand-new unit. These heads are professionally remanufactured, machined to factory specifications, and pressure-tested to ensure durability. While sold bare (without valves, springs, or seals), they offer an excellent base for technicians who wish to transfer or install new valve components.

New Bare Cylinder Head

For those who prefer factory-new components, the new bare cylinder head option delivers uncompromised reliability. Manufactured to original Detroit Diesel standards, these heads arrive ready for assembly and installation. Choosing a new bare head is ideal when building an engine to zero-hour condition or when dealing with heavy-duty marine and industrial cycles where downtime is not an option.

New Cylinder Head with Valves and Springs

This version includes valves and valve springs pre-installed, saving valuable time during engine rebuilds. Each valve seat and spring is matched to ensure proper sealing, consistent combustion, and balanced valve operation. Suitable for both natural aspirated and turbocharged Series 71 configurations, these heads are ideal for operators who want an easier installation process while maintaining OEM performance.

New Complete Cylinder Head Assembly

The new complete cylinder head assembly is the top-tier option, designed for operators who want an all-in-one solution. Delivered fully assembled with J6 high-performance valves, this head is built to handle demanding operating conditions, including continuous marine duty and heavy industrial cycles. By choosing a complete assembly, you minimize installation time and ensure that every internal component is properly matched.

Gaskets and Sealing Components

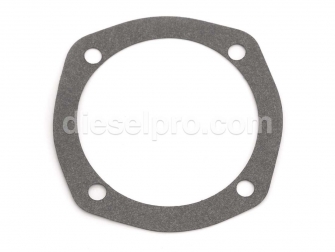

Cylinder Head Gasket Kit

A reliable seal between the cylinder head and block is critical to preventing coolant and compression leaks. The Detroit Diesel 6-71 head gasket kit includes all the required sealing elements to perform a proper head replacement. Using high-quality gasket materials designed to withstand the pressures and temperatures of two-stroke operation, this kit is a must for any top-end service.

Rocker Cover Gaskets

Available in both old-style black rubber and new-style gray rubber variations, rocker cover gaskets ensure oil containment under the valve cover. Replacing these gaskets during head service prevents oil seepage and keeps the engine compartment clean and safe.

Water Manifold and Governor Gaskets

Additional sealing solutions include water manifold gaskets and governor gaskets, both designed to maintain fluid and pressure integrity at key junctions. These small but critical gaskets prevent coolant leaks and ensure smooth fuel management.

Valve Train Components

Exhaust Valves and Intake Valves

The U-style exhaust valves for Series 71 engines are engineered to withstand the high-temperature environment of continuous operation. Precision seating ensures proper exhaust flow and contributes to maintaining compression levels in naturally aspirated configurations.

Valve Seals and Guides

Valve seals prevent oil from leaking into the combustion chamber, while valve guides maintain precise alignment for each valve’s vertical movement. Together, these components protect the cylinder head from premature wear and extend the life of the entire valve train.

Valve Springs and Seats

Heavy-duty valve springs maintain proper valve timing and closure under demanding loads. Combined with valve seat inserts, they provide a durable interface for valve operation. Proper maintenance of these components is essential for operators aiming to maximize fuel efficiency and power output.

Valve Caps, Washers, and Retainers

Supporting elements such as valve caps, spring washers, and retainers are available to ensure complete assembly. Each small part plays a critical role in keeping the valve mechanism stable, balanced, and resistant to vibration under full load.

Cylinder Head Hardware and Accessories

Head Bolts and Plug Kits

OEM-grade head bolts ensure even torque distribution, reducing the risk of warping or leaks. The 6-71 plug kit provides the necessary plugs and fittings for sealing coolant and oil passages within the cylinder head.

Valve Covers

The catalog includes several valve cover options—with oil fillers, breathers, and used but refurbished options. Each valve cover is inspected, sandblasted, and primed to deliver reliable protection for the valve train.

Breather Elements and Seals

Breather systems prevent excess crankcase pressure while allowing proper ventilation. High-quality breather elements and seals help reduce oil misting and keep contaminants out of the engine.

Fuel System Connections and Injector Tubes

The cylinder head also houses the injector tubes and fuel line connections, which are critical for delivering precise fuel quantities to each cylinder. Components include:

-

Injector tubes engineered for correct fit and fuel sealing.

-

Fuel line connectors, washers, and jumper lines (short and long).

-

Specialty tools such as the nut wrench and flaring die to ensure leak-free installation and reconditioning.

By maintaining these components, operators ensure consistent fuel delivery and balanced combustion across all six cylinders.

Rocker Arms, Shafts, and Cam Followers

The rocker arm assembly translates camshaft motion into valve operation. Both left-hand and right-hand rocker arms, along with injector rocker arms, are available. Supporting components include:

-

Rocker arm shafts that maintain alignment and lubrication.

-

Rocker arm brackets and bolts for secure installation.

-

Cam followers and push rods that transfer camshaft lift to the rocker arms.

-

Push rod springs, retainers, and seats to stabilize valve motion and reduce wear.

Together, these parts form the mechanical backbone of the cylinder head’s motion system.

Cooling and Water System Connections

The cylinder head plays a direct role in engine cooling. Available parts include:

-

Water manifold gaskets and studs for sealing coolant passages.

-

Cylinder head water outlet plates for routing coolant flow.

-

Gaskets for the fresh water pump and other coolant interfaces.

Maintaining these cooling connections is vital for preventing overheating, especially in marine environments where engines run for extended hours under load.

Specialty Tools for Cylinder Head Service

To support professional maintenance, Diesel Pro Power offers precision tools such as:

-

Feeler gauges (.002" to .025") for calibrating valves to factory clearances.

-

Injector tube flaring dies for correct fuel line sealing.

-

Socket wrenches for injector fuel line installation and removal.

These tools ensure accuracy during service and extend the life of both new and rebuilt cylinder head components.

Why Choose Diesel Pro Power for Detroit Diesel 6-71 Cylinder Head Parts

Choosing the right supplier is just as important as selecting the right component. A cylinder head is the heart of your Detroit Diesel 6-71 non-turbo engine, and you need a partner who understands the demands of marine and industrial applications. Diesel Pro Power delivers more than just parts—we provide reliability, expertise, and peace of mind for operators worldwide.

Trusted by 40,000+ Customers Worldwide

For decades, Diesel Pro Power has supported commercial fleets, shipyards, power plants, and independent operators with the highest quality Detroit Diesel components. Our reputation is built on long-term customer loyalty, with repeat buyers who trust our parts to keep their vessels and equipment running efficiently. This track record gives you the confidence that every cylinder head and related component has been tested by thousands of real-world applications.

Global Shipping to Over 180 Countries

Downtime costs money, whether it’s a vessel waiting in port or an industrial generator offline. That’s why Diesel Pro Power offers fast, trackable international shipping that reaches customers in more than 180 countries. No matter where your Detroit Diesel 6-71 operates—offshore, inland, or remote locations—you can count on timely deliveries that keep your operations moving without unnecessary delays.

Complete Catalog in One Place

Instead of chasing multiple vendors or searching through outdated catalogs, Diesel Pro Power gives you everything in one streamlined source. Our inventory covers the entire 6-71 non-turbo cylinder head system—from complete heads to the smallest washer, bolt, or gasket. This means fewer headaches during maintenance, easier ordering, and guaranteed compatibility across every component you purchase.

Exclusive Focus on Marine & Industrial Engines

Unlike general parts suppliers who cater primarily to automotive markets, Diesel Pro Power is dedicated exclusively to marine and industrial diesel engines. That focus translates to deeper knowledge, better stock availability, and a product range designed for the continuous-duty cycles that the Detroit Diesel 6-71 is known for. You’re not just buying a part—you’re buying into a supply chain that understands the difference between a truck engine and a workhorse marine engine.

Expert Technical Support Tailored to Your Engine

Even seasoned mechanics benefit from expert advice when it comes to two-stroke Detroit Diesel engines. Diesel Pro Power’s technical team provides personalized assistance on choosing the right head configuration, gasket kits, valves, seals, and injector-related parts for your exact setup. Whether you’re dealing with a single engine overhaul or maintaining an entire fleet, our team ensures that you receive the correct part the first time, avoiding costly trial-and-error mistakes.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588