Parts for Detroit Diesel 6V71 Turbo - Gasket Section

Loading...

Loading... Parts for Detroit Diesel 6V71 Turbo – Gasket Section

A reliable seal is what keeps a Detroit Diesel 6V71 Turbo running clean, cool, and leak-free under boost. Heat cycles, vibration, and sustained turbocharger pressure make gasket quality and fitment especially important on the 6V71 Turbo platform. Below you’ll find an expanded, buyer-friendly guide to every gasket and sealing accessory in this section—what it does, where it lives on the engine, how to spot wear or failure, and practical installation notes so you can finish your job the right way the first time. Where certain pieces are cross-series (shared with other 71/92 engines), we’ll still keep the spotlight on the 6V71 Turbo to help you source confidently.

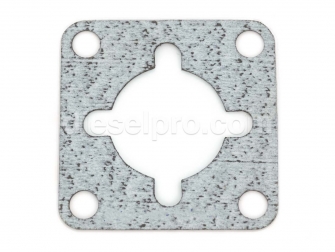

Block Plug Gasket (2.5" Dia) — Sealing coolant gallery plugs the right way

What it does & location. The block plug gasket seals the 2.5-inch core/freeze plug opening on the side of the cylinder block, preventing coolant seepage under pressure. On a turbocharged 6V71, cooling stability is crucial, since elevated EGTs and boost translate into higher thermal loads across the block and head.

Failure signs. Look for green or rusty streaks below the plug, dampness after cool-down, or a faint syrupy smell. Under boost, marginal seals often mist rather than drip.

Fitment & tips. Clean the seat thoroughly with non-marring abrasives, remove scale, and degrease. Lightly oil the gasket if specified by your procedure; do not use excess sealant unless called for. Press the plug squarely to avoid a cocked fit that can scuff the new gasket.

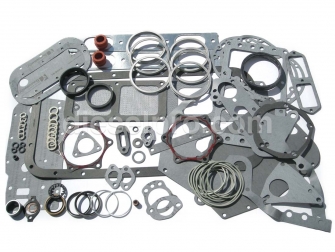

Complete Engine Overhaul Gasket Kit for 6V71 — One kit to reseal the top and bottom end

What it does & contents overview. The overhaul kit bundles the primary soft goods you’ll need during a full refresh: head and base gaskets, intake/exhaust, rocker cover, oil pan, water and oil transfer seals, governor and blower interfaces, and miscellaneous o-rings. It’s purpose-built for the 6V71, reducing second trips and part-match headaches.

Why it matters on turbo builds. Turbocharged 6V71 engines are less forgiving of minor vacuum or pressure leaks. Replacing only a few gaskets while leaving others aged can cause staged failures. The kit approach renews the system so crankcase pressure, intake charge, and coolant all stay where they belong.

Pro tip. Lay out the kit on a clean bench and bag/label by subsystem—“Head & Valve Train,” “Air Handling,” “Lubrication,” “Cooling,” “Front/Rear Structure”—so reassembly flows and nothing is overlooked.

Inspection Block Cover & Inspection Cover Gaskets — Leak-free access panels

What they do. These thin-profile gaskets seal the small access plates on the block. On a 6V71 Turbo, even small weeps can leave tell-tale grime stripes from crankcase pulsation.

Install notes. Scrape gently to avoid gouging. Light, even torque on fasteners is the difference between a perfect seal and a wavy, weeping cover.

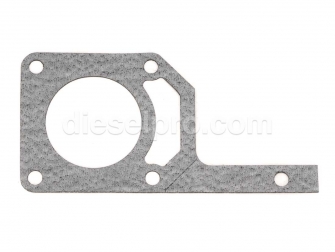

Front End Plate Gasket (V71 & V92) — Structure interface sealing

Role on the engine. Sits between the block and front end plate (timing/gear train cover area). Any leak here quickly tracks downward, confusing diagnosis.

Turbo note. Front leaks can make belts slip and contaminate the crank seal. Replace during any front-drive or accessory service.

Front Crankshaft Seal (Standard, Universal Rotation) — Keep oil in at the snout

Function. Seals the crank snout at the front cover where accessory drives and the damper live.

Symptoms of failure. Oil sling on the damper or belts; wetness behind the pulley; smoke or smell on hot parts.

Install tip. Inspect the wear groove on the crank hub; polish lightly if needed. A straight, square drive-in with the correct tool prevents lip distortion.

Rear Crankshaft Seals — Single-lip vs. Double-lip, Standard vs. Oversize

Choosing the right configuration.

-

Single-lip (Standard/Oversize): Good sealing when the shaft surface is pristine.

-

Double-lip (Standard/Oversize): Added protection where minor shaft wear or pressure pulses exist—common on hard-worked turbo engines.

When to go oversize. If the crank journal shows a measurable groove where the old seal rode, an oversize plus a sleeve can restore sealing without crank replacement.

Best practice. Pair rear seal work with a close inspection of the rear main bearing cap mating surfaces and the flywheel housing gasket; sealing is a system.

Seal Sleeve (Rear for 71; Front for select 92 applications) — Rebuild the sealing surface

Why use it. A thin, hardened sleeve provides a fresh, concentric surface for the new seal lip.

Tip. Dry-fit, mark depth, then apply the specified adhesive or retainers. Press evenly to avoid an eccentric wobble that’ll defeat your new seal.

Cylinder Head Gasket Kit for 6V71 (two kits required per engine) — Top-end sealing that stands up to boost

What’s inside. Head gaskets, intake/exhaust port seals, valve train cover interfaces, and related o-rings.

Turbo-specific advice. Check liner protrusion, deck flatness, and head warp to spec before committing new gaskets. Turbo cylinder pressure magnifies any out-of-flatness. Torque heads in sequence with a calibrated wrench, and re-verify after initial heat cycle if your service guidance calls for it.

Rocker Cover (Valve Cover) Gasket Kit — New-style kit for aluminum covers

Why it matters. Oil mist from a valve cover weep gets drawn toward the turbo inlet, loading the compressor with grime. New-style profiles for aluminum covers resist cold-flow and improve long-term elasticity.

Install tip. True the cover rail; small bends along the bolt holes are common and cause waves that leak.

Water Manifold (Water Rail) Gasket — No drips along the coolant log

Function. Seals the water manifold to the head/block transfer ports.

Checks. Look for pitting at the mating flange; a pitted rail will cut into even a new gasket under clamp load.

Flywheel Housing & Rear End Plate Gaskets — Stable sealing at the rear structure

Why replace together. A fresh flywheel housing gasket is only as good as the end-plate seal behind it. Doing both during clutch/flywheel or ring-gear work prevents repeat labor.

Turbo context. Rear oil leaks can fling onto the bell housing and clutch, creating chatter or smoke under load.

Fuel/Water Pump & Auxiliary Pump Gaskets — Small parts, big leaks if ignored

Use cases. Anytime a pump is removed for service, budget a new paper/fiber gasket. A reused, compressed gasket rarely reseals perfectly on boosted engines that see sustained RPM.

Tip. Dry fit and check for even flare on captive nuts/studs; uneven clamp loads are a silent cause of weeping.

Allison Marine Transmission Flywheel Housing Gasket (SAE #2) — Clean connection to your gear

Purpose. Seals the joint between engine flywheel housing and Allison M/MH marine gear when both share SAE #2 sizing.

Marine note for 6V71 Turbo. A tidy, dry interface helps keep the bilge clean and protects couplers and damper plates. Always verify your housing size before ordering.

Oil Cooler Gaskets — Keep oil and coolant in their lanes

What they do. Seal the oil cooler core and cover interfaces so oil and coolant never cross-contaminate.

Red flags. Milky oil film, unexplained coolant loss, or rising oil level. After gasket replacement, pressure-test before closing.

Blower Installation Gasket Kit — Essential on every blower pull

Why it’s special on a turbo 6V71. The 6V71 uses a Roots-type blower; on turbo engines the blower sees positive inlet pressure. Any gasket leak at the blower base, inlet, or striker plate becomes a boost leak that hurts power and air-fuel balance.

Pro tip. Check rotor-to-case clearances and end play while the blower is off; sealing is only half the story—mechanical health is the other half.

Governor Spring & Governor Top Cover Gaskets — Precise control, no seepage

Function. Seal the governor covers so speed control stays clean and leak-free.

Install advice. Keep fasteners even and don’t over-crush thin paper gaskets. Oil seepage here attracts dust that can interfere with linkage motion over time.

Turbo Exhaust Inlet Connection Gasket — Hot-side sealing under boost

Duty. Seals the turbine inlet junction. A leak here results in soot trails, slower spool, and higher EGT upstream.

Fit check. Dry-fit flanges for flatness; a bowed flange will burn a new gasket quickly. Use the correct hardware and tighten in a cross-pattern.

Turbo Riser Gasket — Correct dimensions for a clean, laminar path

What to know. The inner/outer dimensions are matched to the 6V71 turbo riser to maintain gas velocity and avoid blow-by.

Best practice. Pair with clean, de-scaled mating faces. Avoid over-sealant; excess can intrude into the gas path and overheat.

High-Temperature Jointing Compound (762) — The right sealant for extreme heat

Use cases. Turbo flanges and exhaust joints that see continuous high temp.

Technique. Apply a thin, even film; more is not better. Allow the recommended cure before lighting off. Perfect for helping gaskets conform to minor flange imperfections.

Turbo Oil Return & Turbo Oil Supply Gaskets — Keep the CHRA happy

Why they matter. Supply and drain leaks create smoke, fire risk, and bearing distress. The return side must remain restriction-free—any kink, silicone squeeze-out, or misaligned gasket will pool oil in the center housing.

Tip. Prime the turbo with clean oil before startup and verify drain angle (continuous fall to the crankcase).

Oil Pan Gasket (6V71/6V92) — Base-end sealing that resists vibration

Symptoms of failure. Persistent wet rail along the pan, drips at corners, or a dust-oily cake.

Install best practices. True the pan rail with a straightedge and dolly the bolt holes flat; years of over-torque dish the holes and create sealing “volcanoes.”

Hydraulic Governor Gasket (Governor-to-Drive) — No cross-leaks

Purpose. Maintains a clean interface between the hydraulic governor and its drive.

Tip. Clean dowel bores; a bound dowel can hold the assembly off the gasket and cause a line leak that’s hard to spot.

Oil Filter Adaptor Gasket — Stop seepage at the filter base

Clues you need one. Oil film around the filter base even after replacing filters and properly oiling the seal.

Pro move. Inspect adaptor flatness; aluminum faces can warp. Light stoning restores a flat plane for the gasket to grip.

Marine Raw Water Pump Gaskets: Body, Mounting, Plate, Inlet/Outlet — Four ways to stay dry

Gasket map.

-

Pump body gasket: Seals the pump housing split line.

-

Mounting gasket: Seals the pump to bracket or flywheel housing.

-

Plate gasket: Seals the cover plate (common service point for impeller checks).

-

Inlet/Outlet gaskets: Two per pump—one for each hose flange.

Marine tip. Salt crystallizes under marginal seals; after service, rinse and inspect. Use anti-seize on fasteners to ease future maintenance.

Flywheel Housing Cover (Large Cover) — Keep the bell dry and clean

Use case. Reseal during ring gear, damper, or rear main service.

Why it matters. A sealed housing stays cleaner, making future leak diagnosis faster and keeping contaminants away from the ring gear and starter.

Flywheel-to-Raw Water Pump Gasket — Coupled accessory integrity

Role. Seals the interface on configurations where the raw water pump mounts at the flywheel housing.

Checklist. Verify bracket alignment and shim as necessary to prevent flange pinch and premature gasket crush.

General 71/92 Series Gasket — The handy utility seal

When to use. As specified in your parts diagram where a generic, series-wide gasket is called out (inspection plates, auxiliary covers, etc.).

Advice. Match by outline and fastener pattern, not just by name, to ensure a perfect fit.

Thermostat Housing Cover Gasket — Temperature control without seepage

Why it matters. Any air drawn in at the thermostat cover can create hot spots and erratic thermostat behavior.

Install tip. Clean corrosion grooves; a light coat of appropriate sealant can help fill micro-pits.

Marine Heat Exchanger Gasket Kit (53/71/92) — Keep your closed-loop side sealed

Contents & use. End-cap gaskets, body interfaces, and related seals for marine heat exchangers used with the 6V71 Turbo.

After install. Pressure-test the exchanger and check for weeping under load after the first sea trial.

Block Water Outlet / Block Heater Gasket — Dry, safe winterization point

Role. Seals the block outlet where a heater or plug installs.

Watch-outs. Mineral deposits under the flange will undermine sealing. Clean to bare metal prior to install.

Starter Gasket — A small seal with big cleanliness payoff

Why bother. Oil mist around the starter makes electrical issues harder to diagnose and accelerates grime buildup. The correct gasket keeps the mount area dry.

Engine Paint (Detroit Green) — The last seal in your toolkit

Why paint belongs here. A proper repaint after degreasing and resealing helps reveal future leaks fast. Fresh paint makes even a small oil track obvious so you can fix it early.

Hydraulic Governor Cover Gasket (Series 53/71/92) — Tidy top-side sealing

Function. Seals the governor cover to keep oil in and contaminants out.

Tip. Replace whenever you pull the cover to adjust springs or inspect internals.

Sealants & Compounds — When and how to use them on a 6V71 Turbo

High-tack gasket spray. Great for paper gaskets that must stay put during assembly (oil pan, timing covers, access plates). Light, even coats only.

Liquid gasket maker (non-hardening). Ideal where thermal cycling and small movements occur; it stays pliable.

Sensor-safe RTV (standard & high-temp). Use sparingly at corners and joints where the factory procedure calls for a form-in-place seal. Sensor-safe formulas prevent O2 or temperature sensor damage in mixed fleets.

Threadlocker (high strength, red). For studs/fasteners that must not back out under vibration (exhaust/turbo brackets). Apply per spec; avoid drowning threads near gasketed interfaces.

Cold-weld epoxy. Emergency or supplemental repairs on non-critical, non-pressurized castings. Not a substitute for a proper gasket under pressure or heat.

High-temp jointing compound (762). Purpose-built for turbo/exhaust joints; a small amount enhances sealing at very high temps.

Gaskets for Detroit Diesel 6V71 Turbo — Selection & Installation Playbook

Match by engine, location, and material. The 6V71 Turbo can use composite, fiber, graphite, or metal-layer gaskets depending on the joint. Choose the material engineered for that heat, pressure, and media (oil/coolant/exhaust).

Confirm standard vs. oversize on seals. Measure crank seal journals and inspect for grooves. Oversize seals and sleeves are excellent fixes when surfaces are worn.

Prepare the surfaces. Degrease, remove old material completely, chase threads, and lightly stone flanges to remove raised lips around bolt holes. A clean, flat, dry surface is 90% of leak prevention.

Dry vs. dressed. Use sealants only where specified. Many modern gaskets seal best dry; excess sealant can cause gasket creep, extrusion, or contaminate oil passages.

Torque and sequence. Follow Detroit Diesel torque charts and patterns—especially on the head, blower base, end plates, and covers. Re-torque after initial run if your service literature requires it.

Mind the turbo system interfaces. On the hot side (exhaust inlet, riser), ensure flange flatness and correct hardware. On the oil side (feed/return), maintain free drain and avoid sealant squeeze-out. On the air side (blower to manifold), any leak is a boost leak—use fresh gaskets and verify clamp load.

Replace related wear parts while you’re in there. If you’re doing a rear main seal, consider the flywheel housing gasket and cover. If the blower’s off, refresh the striker plate gasket. Bundling tasks reduces repeat labor.

Document what you install. Note which seals are oversize or if a sleeve was used. Future you—or the next tech—will thank you when it’s time to service again.

Troubleshooting 6V71 Turbo Sealing Issues

Oil at the bell housing weep hole: Often rear main seal, but verify flywheel housing gasket and end-plate gasket. UV dye helps pinpoint.

Oil film near the damper/pulleys: Front crank seal or front end plate gasket; confirm crank hub wear before installing a new seal.

Soot at turbo inlet flange and slow spool: Exhaust inlet connection gasket; check for warped flange and tighten in sequence.

Oily intake piping or compressor wheel fouling: Rocker cover or blower base leaks allowing mist into the intake stream; renew those gaskets and check crankcase ventilation.

Coolant smell near the block side: Water rail manifold or block plug gasket; pressure-test cooling system after replacement.

Persistent pan rail drips after a fresh gasket: Pan rail distortion (“peaked” bolt holes). Dress the rail, use proper torque, and recheck after heat cycles.

Parts Mapping Quick Guide for the 6V71 Turbo (What you’ll typically use and when)

-

During full rebuilds: Overhaul gasket kit, head gasket kits (two), oil pan, front/rear end plate, flywheel housing, blower base/striker plate, governor cover and spring cover gaskets, water rail, oil cooler, thermostat cover, inspection covers, starter gasket, plus appropriate crank seals (and sleeve if needed).

-

Top-end refresh: Head gasket kits, rocker cover kit (aluminum cover style), blower and governor cover gaskets, thermostat housing, water rail, inspection covers.

-

Turbo/exhaust service: Turbo inlet connection gasket, turbo riser gasket, high-temp jointing compound, turbo oil supply and return gaskets; examine manifold joints and replace as needed.

-

Marine cooling service: Heat exchanger gasket kit, raw water pump body/mounting/plate/inlet-outlet gaskets, flywheel-to-pump gasket; pressure test after assembly.

-

Driveline interface: Flywheel housing gasket and cover gasket; on marine units, the SAE #2 Allison interface gasket when coupling to M/MH gears (verify sizing).

Care, Storage & Handling Tips for Gaskets and Seals

-

Keep flat and clean. Store kits flat, in sealed bags away from sunlight and solvent fumes.

-

Dry test-fit. Especially on irregular covers. A quick dry run avoids surprises when the sealant clock is ticking.

-

Replace hardware if needed. Stretched or rusty bolts don’t clamp evenly.

-

Mark torque steps. On critical joints (head, blower), mark each fastener as you complete steps to maintain pattern integrity.

-

Initial run-in check. After first heat cycle, scan for weeps and re-inspect clamp loads where procedures recommend.

Why Buy Your 6V71 Turbo Gaskets from Diesel Pro Power

When you’re resealing a Detroit Diesel 6V71 Turbo, the right parts—and the right partner—save you time, money, and repeat labor. Diesel Pro Power combines quality-controlled sourcing, meticulous cataloging by engine model, and seasoned product support so you order once and install with confidence.

-

Engine-model focus. This catalog is built around the 6V71 Turbo—you won’t sift through unrelated listings to find what fits.

-

Quality you can count on. Gaskets and seals are selected to handle the heat, pressure, and vibration environment of a turbocharged 2-stroke Detroit.

-

Clear, practical fit notes. We include plain-language placement and use-case guidance so you know exactly where each gasket belongs.

-

Marine-friendly coverage. If your 6V71 Turbo is in a vessel, you’ll find the raw water and heat exchanger gaskets you need alongside engine items, plus the SAE #2 interface gasket for Allison M/MH gear pairings when applicable.

-

Fast shipping & real inventory. “In Stock” means ready to move—keeping your downtime to a minimum.

-

Trusted by 40,000+ satisfied customers. Mechanics, captains, and fleet managers alike rely on Diesel Pro Power to keep Detroit's sealed and at work.

-

Human support. Need a second set of eyes on an order? Our team can help you match standard vs. oversize seals, confirm interface gaskets, and suggest best-practice kits for your service scope.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588