Parts for Detroit Diesel 6V71 Non-Turbo - Exhaust Section

Loading...

Loading... Parts for Detroit Diesel 6V71 Non-Turbo – Exhaust Section

The Detroit Diesel 6V71 Non-Turbo engine, part of the legendary Series 71 family, has been a mainstay in marine, industrial, and vehicle applications for decades. Known for its durability and mechanical simplicity, this two-stroke engine requires a carefully balanced exhaust system to maintain its performance and temperature control. The following catalog details the full range of exhaust-related components available from Diesel Pro Power—each engineered to OEM specifications, fully tested, and ready for installation.

Exhaust System Overview for the Detroit Diesel 6V71 Non-Turbo

The exhaust system on the 6V71 plays several crucial roles: it routes burned gases safely out of the cylinders, reduces backpressure for smoother power output, maintains optimal engine temperature, and, in marine configurations, ensures water-cooling efficiency. Marine engines often require corrosion-resistant manifolds and fittings, while industrial versions need durable high-temperature insulation and vibration-resistant mounting hardware. Diesel Pro Power provides complete coverage for both configurations.

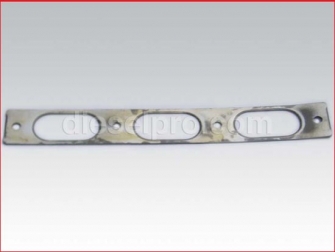

Gasket – Turbo Exhaust Inlet Connection

Although the 6V71 Non-Turbo doesn’t utilize a turbocharger, many installations include exhaust connection points or retrofitted components requiring precision gaskets. The gasket for the exhaust inlet connection ensures a perfect seal between the manifold and adjoining exhaust components, preventing hot gas leaks and maintaining pressure integrity. Constructed from multi-layer heat-resistant materials, this gasket is engineered to handle extreme conditions found in marine engine rooms or industrial generator housings.

Its exact fit and robust composition make it essential during manifold installation or replacement, avoiding exhaust blow-by that can damage insulation or nearby wiring.

Marine Manifold – Water-Cooled Exhaust Manifold

The Detroit Diesel Marine Manifold for the 6V71 is one of the most critical elements in the entire exhaust system. Water-cooled to prevent overheating, it channels exhaust gases from the cylinders while maintaining a controlled temperature. Diesel Pro Power supplies new manifolds, not merely reconditioned or welded versions, ensuring that each casting meets factory flow and thermal specifications.

These manifolds are compatible with multiple Series 71 and 92 engines, but when installed on the 6V71 Non-Turbo, they provide optimal exhaust scavenging and heat exchange efficiency. The corrosion-resistant coating and precision-machined ports help reduce maintenance intervals—especially valuable for vessels that run continuously in saltwater environments.

Head to Manifold Gasket

The head-to-manifold gasket seals the interface between the engine head and the manifold. It prevents exhaust leakage, ensures equal pressure across all cylinders, and guards against the thermal expansion stresses that develop under load. This gasket is designed to handle the high exhaust gas temperatures typical of two-stroke diesel combustion and is an essential component whenever the manifold is removed for inspection or cleaning.

Detroit Diesel 6V71 and 6V92 engines share this gasket type, which simplifies parts sourcing for mixed fleets. Diesel Pro Power’s gaskets are manufactured using reinforced graphite and metal composite materials, extending life far beyond conventional paper or fiber designs.

Manifold Insulation Tape

Manifold insulation tape serves a dual purpose: it retains heat within the exhaust manifold for improved exhaust flow and shields surrounding components from radiant heat. Available in 3-inch and 4-inch widths, each roll provides 100 feet of high-temperature fiberglass material, 1/8 inch thick.

In marine installations, insulation prevents heat buildup in confined engine rooms, protecting hoses, wiring, and personnel. On industrial engines, it maintains safer ambient operating conditions and can slightly improve fuel efficiency by reducing exhaust gas cooling losses. Diesel Pro Power’s insulation tape withstands temperatures above 1000°F (540°C), maintaining flexibility and adhesion over time.

Manifold Mounting Hardware – Studs, Crabs, Washers, and Nuts

A reliable exhaust system begins with precision fasteners. Diesel Pro Power offers complete mounting hardware for the Detroit Diesel 6V71:

-

Manifold Studs: Precisely machined studs (7/16”-14/20 x 2.10”) ensure even pressure across the manifold surface. They’re manufactured from high-tensile steel to resist vibration loosening.

-

Manifold Crabs: These unique clamp-style retainers hold the manifold sections securely in place, distributing stress evenly.

-

Washers and Nuts: Heat-resistant washers and self-locking nuts complete the mounting system, minimizing the risk of loosening due to thermal cycling.

Each component is corrosion-resistant and matches original Detroit Diesel design tolerances for trouble-free installation.

Marine Manifold Water Outlet Plates and Gaskets

The water outlet plate and its corresponding gasket are vital in the 6V71’s marine exhaust manifold. They manage the flow of cooling water that circulates around the manifold jacket. Diesel Pro Power’s replacement plates are machined from marine-grade metal, ensuring longevity in saltwater environments.

The manifold water outlet gasket provides a tight, reliable seal that withstands continuous exposure to hot coolant and exhaust moisture. Together, they prevent leaks and maintain the proper temperature differential essential for exhaust gas cooling.

Threaded Plates and Elbows for Marine Applications

The threaded plate for marine manifolds features a ¾-inch thread design and is often used to connect fittings for water drain or temperature sensors. It is critical that these plates are made from corrosion-resistant materials since they are exposed to both exhaust gases and seawater.

Complementing these are marine manifold elbows, available in 45- and 90-degree angles with ¾-inch and 1-inch threaded options. These elbows allow technicians to route water and exhaust lines efficiently, reducing strain on hoses and maintaining compact installation geometry. Diesel Pro Power’s elbows feature precision threads and smooth internal surfaces for unrestricted flow and reduced turbulence.

Industrial Exhaust Components – Flanges, Gaskets, and Mufflers

For land-based or stationary applications, Diesel Pro Power offers a complete lineup of industrial exhaust components designed for the 6V71 Non-Turbo configuration:

-

Exhaust Flanges: 4-inch inside diameter flanges connect the manifold outlet to piping or mufflers.

-

Flange Gaskets: High-temperature gaskets ensure airtight joints between flanges and prevent soot leakage.

-

Industrial Mufflers: Designed to reduce exhaust noise while maintaining optimal backpressure. The mufflers feature 4-inch threaded inlet and outlet ports and are constructed from heavy-gauge steel with rust-resistant coatings.

Each of these components is engineered to provide reliable operation in generator sets, compressors, and heavy-duty equipment powered by Detroit Diesel engines.

Muffler Caps and Flexible Exhaust Hoses

Muffler caps are simple yet essential accessories for engines exposed to the elements. They prevent rain, spray, and debris from entering the exhaust system when the engine is shut down. Diesel Pro Power offers caps in multiple diameters—3", 3.5", 4.5", and 5"—to match various muffler outlet sizes. Each cap is built from stainless or galvanized steel, with a hinge design that automatically opens under exhaust pressure and closes when the engine stops.

For flexible exhaust connections, the metal exhaust hose (4” x 18”) absorbs vibration and movement between the engine and exhaust piping. This flexibility prevents stress fractures in manifolds or rigid pipe joints. Constructed from reinforced corrugated metal, these hoses can endure both high temperatures and continuous vibration—an essential feature in marine engine rooms and industrial setups alike.

Temperature Switch – Engine Safety Component

The temperature switch serves as a safeguard in the exhaust and cooling system, activating alarms or shutoffs when the engine temperature exceeds 205°F. It uses a standard ½-inch NPT thread for universal fitment across Detroit Diesel, Cummins, and Caterpillar engines. Maintaining correct operating temperature is crucial for two-stroke engines like the 6V71, as overheating can lead to warped manifolds or premature gasket failure. This small but vital component helps operators monitor conditions in real-time.

Detroit Green Paint – OEM Color Finish

Restoring a Detroit Diesel engine to its factory look involves the correct Detroit Green paint. Specially formulated for engine surfaces, this paint resists oil, heat, and corrosion. Beyond aesthetics, the coating helps protect metal surfaces from oxidation in humid or marine environments. Diesel Pro Power provides the authentic color used across the entire Series 71 lineup, available for ground shipment throughout the U.S. and Canada.

Gauges and Instrumentation

Accurate temperature and pressure readings are essential for monitoring exhaust performance. Diesel Pro Power carries a range of mechanical and electrical gauges, available in both 12-volt and 24-volt configurations, with or without built-in alarms. These instruments ensure the operator can detect overheating or backpressure changes before they cause damage. Using reliable gauges extends the lifespan of exhaust components by maintaining proper operating parameters.

Why Maintaining a Healthy Exhaust System Matters

A well-maintained exhaust system directly affects the Detroit Diesel 6V71’s performance, noise level, and longevity. Blocked or leaking manifolds increase exhaust temperature, reduce power, and raise the risk of thermal damage. By replacing worn gaskets, fasteners, and insulation, operators can restore factory efficiency. Properly functioning exhaust components also minimize carbon buildup, which is especially important in marine engines that operate at variable loads.

Why Buy Detroit Diesel 6V71 Non Turbo Exhaust Parts from Diesel Pro Power

Trusted by Over 40,000 Satisfied Customers Worldwide

Diesel Pro Power has built a global reputation as the premier source for Detroit Diesel parts. Each product is quality-checked for compatibility, ensuring that mechanics and operators receive components that fit perfectly the first time. From engine rooms aboard tugboats to industrial powerplants, Diesel Pro Power parts perform reliably under pressure.

OEM-Grade Quality and Expert Support

Every exhaust component—from the smallest gasket to the largest manifold—is backed by Diesel Pro Power’s commitment to precision manufacturing. The company’s experts provide detailed installation guidance and support, reducing downtime and ensuring correct fitment for both left-hand and right-hand engine configurations.

Fast Global Shipping and Real-Time Tracking

Diesel Pro Power’s streamlined logistics system allows customers around the world to receive their parts quickly. Orders are processed promptly, with real-time tracking updates to keep maintenance schedules on track.

Marine and Industrial Expertise

Few suppliers understand Detroit Diesel’s legacy engines like Diesel Pro Power. Their decades of experience with the 6V71 mean customers can trust every gasket, elbow, and manifold to meet the rigorous demands of marine and stationary service.

Comprehensive Inventory Under One Roof

Whether you need insulation tape, exhaust studs, or full muffler assemblies, Diesel Pro Power maintains one of the most complete inventories of Detroit Diesel components anywhere. This all-in-one access helps reduce lead times and simplifies sourcing, particularly for fleet operators maintaining multiple Series 71 engines.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588