Parts For Detroit Diesel 8V92 Turbo - Gasket Section

Loading...

Loading... Gaskets & Seals for Detroit Diesel 8V92 Turbo — Complete Catalog Guide

The Detroit Diesel 8V92 Turbo is a high-output, two-stroke, V-configuration engine widely trusted in marine propulsion, commercial fishing vessels, workboats, standby power, and heavy industrial applications. Keeping this engine dry, clean, and in spec depends on a comprehensive gasket and seal strategy—from the crankcase and cylinder liners to the turbo oil lines and marine exhaust interfaces. This expanded guide organizes every gasket and seal you see on this page into practical, 8V92-Turbo–focused categories. You’ll find what each component does, where it goes, how to select the correct variation (standard vs. oversize, single-lip vs. double-lip, right-hand vs. left-hand rotation), and best practices for installation, inspection, and maintenance.

Use this as your field-ready reference when planning an overhaul, addressing a coolant or oil leak, resealing a turbo interface, or refreshing a marine exhaust connection. All guidance below is tailored to the 8V92 Turbo specifically; where a gasket also fits other Series 92 or V-series engines, we point that out only to clarify compatibility while keeping the focus on your 8V92 Turbo application.

What This Section Covers

-

Lower end & crankcase sealing: front and rear crankshaft seals, end-plate and flywheel housing gaskets, oil pan gasket, and liner sealing.

-

Upper end & cylinder head sealing: head gasket kits (quantity required for an 8V92), rocker cover gaskets (old/new style), and water manifold interfaces.

-

Air handling & turbo/blower interfaces: blower installation gasket kit for turbo engines, turbo riser and oil line gaskets, plus head-to-manifold and marine exhaust flange gaskets.

-

Cooling system & oil cooler interfaces: oil cooler gaskets, heat exchanger sealing, raw-water pump mounting and plate gaskets, and block water outlet.

-

Marine transmission interface: flywheel housing gaskets for Allison M and MH series commonly paired with 8V92 Turbo in marine service.

-

Sealants & consumables: high-temperature jointing compound for turbo joints, RTV and non-hardening sealants, threadlocker, and accessory items like engine paint for final presentation and corrosion protection.

Lower End & Crankcase Sealing for 8V92 Turbo

Cylinder Liner Seals (Block to Liner Interface)

The liner seal sits at the bottom of each cylinder liner to prevent coolant migration into the crankcase and to maintain a stable, leak-free interface between the liner and block. On an 8V92 Turbo, liner seals are critical because two-stroke Detroit Diesels rely on precisely controlled scavenging and tight fluid control.

When to replace: any time a liner is disturbed, decked, or replaced; whenever you see coolant in the oil; or as part of a major overhaul.

Install notes:

-

Inspect the counterbore and liner landing surfaces for pitting, corrosion, or fretting. Address defects before installing new seals.

-

Lubricate seals with the recommended assembly lubricant; don’t use RTV on liner O-rings.

-

Verify liner protrusion after installation and before head assembly; liner protrusion outside spec can overload head gaskets and cause early failure.

Oil Pan Gasket (Crankcase Sump)

The oil pan gasket seals the pan to the crankcase rail. On boats, minor pan leaks can quickly foul bilge areas and trigger oil-contamination issues.

Best practices:

-

Clean and dry both mating surfaces; chase bolt holes to remove oil and debris.

-

Lightly tack the gasket to the pan to prevent creep during installation. Avoid over-torqueing pan bolts; follow a cross-pattern and step torque evenly.

-

Check pan rail straightness. Warped rails create pinch points and weeping.

Front Crankshaft Seals (Right-Hand & Left-Hand Rotation)

The 8V92 Turbo is found in both right-hand and left-hand rotation configurations. Front seals are available specifically for each rotation. Teflon-based sealing lips provide low friction and long life.

Selection rule: match the engine’s crankshaft rotation (as viewed from the flywheel end) and the seal’s stated rotation.

Install tips:

-

Inspect the damper hub surface; a grooved or pitted sealing surface can chew up a new seal. If needed, restore the surface or use a sleeve if specified for the front location.

-

Install squarely with the correct driver. Over-driving or cocking the seal risks lip damage and immediate seepage.

Rear Main Crankshaft Seals (Single-Lip & Double-Lip, Standard & Oversize)

The rear main seal options include single-lip and double-lip designs, standard and oversize diameters, and variants intended for universal, right-hand, or left-hand rotation.

How to choose:

-

Single-lip vs. double-lip: Double-lip seals add a dust or oil deflection lip to improve exclusion of contaminants and better manage splash—helpful in harsh marine environments.

-

Standard vs. oversize: Use oversize only if the crankshaft sealing surface has wear and you’ve installed a rear seal sleeve (or been instructed by service procedure).

-

Rotation-specific versions: Some rear seals are rotation-specific in “new style” designs; always match the engine’s rotation.

Rear seal sleeve: If the crank’s seal journal is grooved, a rear crankshaft sleeve is intended to provide a new, smooth sealing surface sized for the oversize seal. Don’t install an oversize seal without addressing the grooved journal.

Install checklist:

-

Verify the rear main bearing cap alignment and cleanliness.

-

Dry-fit the seal and sleeve (if applicable) to confirm seating depth.

-

Use the approved assembly lube on the sealing lip; don’t grease Teflon lips unless explicitly allowed.

-

After installation, rotate the crank by hand to ensure no drag points.

End Plate & Flywheel Housing Interfaces

-

Front end plate gasket: Seals the interface between the engine block and front end plate. Any weep at this joint can track and appear like a front main leak; address it during timing/cover work or overhaul.

-

Flywheel housing gasket: Sits between the end plate and the flywheel housing. Ensures a clean interface for alignment with marine gear or other bell-housing attachments.

-

Flywheel housing cover: The large cover gasket seals an inspection or accessory opening on the flywheel housing, preventing oil mist escape in high-RPM service.

-

Starter gasket: Creates a clean seal around the starter aperture to control oil mist and bilge odor in marine applications.

Upper End & Cylinder Head Sealing

Cylinder Head Gasket Kits (Quantity for 8V92 Turbo)

The 8V92 uses two head gasket kits (one per cylinder bank). Each kit supports one bank in a V-8 configuration. Ensuring correct liner protrusion and pristine deck surfaces is essential for long-term head gasket life on a high-output turbocharged two-stroke.

Preparation:

-

Measure liner protrusion and record values. If out of spec, correct before head install.

-

Clean deck surfaces to bare metal with plastic scrapers and non-abrasive pads; avoid removing parent metal.

-

Inspect fire rings in the kit and verify coolant/oil port alignment to the block and head.

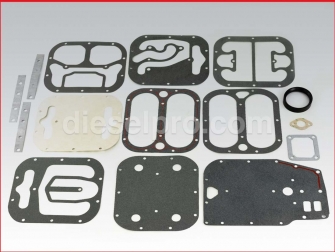

Rocker Cover Gaskets & Kits (Old vs. New Style)

The 8V92 Turbo commonly uses aluminum rocker covers with a new-style gray gasket profile or a complete rocker cover kit where needed.

Selection guidance:

-

If you have aluminum covers with the later profile, choose the new-style gray rubber gasket sized to those covers.

-

If covers are older or heavily worn at the sealing rail, consider the full kit to refresh fasteners, grommets, and seals.

Install tips:

-

Clean the cover rails and cylinder head sealing land.

-

Do not overtighten rocker cover bolts; even compression is far better than high torque.

-

Recheck after first heat cycle; if a gasket has “set,” a small retorque may be appropriate per service guidance.

Water (Coolant) Manifold Gasket

The water manifold gasket (sometimes called the water rail gasket) seals the coolant distribution manifold along the head or block interface, depending on the configuration.

What to watch for:

-

Coolant staining or crusting at the joint indicates seepage.

-

Clean both sides thoroughly; replace fasteners if corrosion is severe.

-

Apply coolant-safe assembly lube where specified; avoid RTV unless the service literature calls for it.

Governor Gaskets (Spring Cover & Top Cover)

Governor cover gaskets seal the spring cover and top cover of the governor assembly on the 8V92 Turbo. While these are small gaskets, a leak here can mist fuel-contaminated oil into the engine room.

Tip: Replace these gaskets whenever the governor is removed for tuning or inspection; they’re inexpensive insurance against nuisance leaks.

Air Handling, Blower & Turbo Interfaces

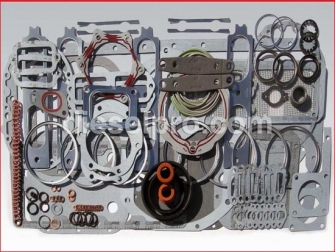

Blower Installation Gasket Kit for Turbocharged Engines

Even turbocharged 8V92 engines retain the Roots-type blower for scavenging. The blower installation gasket kit (turbo version) includes the specific gaskets needed to reinstall or service a blower on an 8V92 Turbo.

When to use:

-

Any blower swap, service, or reseal on a turbo engine.

-

After oil carry-over is detected; oil trails can compromise gasket integrity and attract carbon.

Blower install pointers:

-

Check rotor-to-case clearances if the blower has been renewed.

-

Ensure perfect alignment of the blower to the block to prevent side-load and early seal failure.

-

Always replace the blower base gasket; reuse risks vacuum leaks that harm scavenging efficiency.

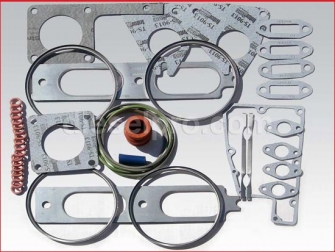

Turbo Riser, Oil Supply & Oil Return Gaskets

-

Turbo riser gasket: Seals the turbo’s outlet connection to the riser or the marine elbow. Turbo joints see extreme heat cycles; use the correct high-temp gasket and ensure flatness on both mating faces.

-

Turbo oil supply gasket and turbo oil return gasket: These support clean oil feed and gravity-assisted return to the crankcase.

Key practices: -

Verify oil feed restrictors and cleanliness; a restriction starves the turbo and can cause catastrophic bearing failure.

-

For the return, ensure the return path is downhill with no sags. A weeping return gasket usually points to a distorted flange or old, cooked gasket material stuck to the surface.

High-Temperature Jointing Compound for Turbo Joints

A high-temperature jointing compound (rated into the 550–760°C range) is ideal for metal-to-metal turbo flanges, studs, and gasket interfaces subject to intense thermal cycling.

Use cases:

-

Light, even film on turbo flange faces if recommended.

-

Threads on studs to ease future service and resist galling.

-

Avoid contaminating oxygen sensor ports or turbo center sections with sealant.

Head-to-Manifold Gaskets & Marine Exhaust Flange Interfaces

-

Head-to-manifold gaskets seal the interface between the cylinder head and exhaust manifold. On turbo engines, these gaskets endure high exhaust energy; replace them whenever the manifold is off or shows hot streaks.

-

Marine exhaust manifold flange gaskets (including spacers and JT-style patterns) adapt the engine to water-cooled manifolds and elbows found on marine 8V92 Turbo packages.

Installation reminders: -

Dry fit the manifold and riser to ensure no pre-load or misalignment; misalignment causes repeated gasket burn-through.

-

Use new hardware where possible and torque in sequence from the center outward.

-

After warm-up and cool-down, recheck flange fastener torque if recommended.

Cooling System & Oil Cooler Interfaces

Oil Cooler Gaskets & Double-Cooler Installation Kit

The 8V92 Turbo often runs dual oil coolers in marine duty. Two common oil cooler gaskets cover the standard cooler end-cap interfaces, and a dedicated double-cooler installation kit provides the pieces needed to mount or reseal twin coolers.

Common leak points:

-

End-cap to housing joints due to thermal cycling.

-

Pitting on mating faces; polish lightly if needed and replace gaskets.

-

O-rings inside the cooler body (not listed in this gasket section) should be inspected during service intervals.

Heat Exchanger Gasket (Marine)

The heat exchanger gasket for V-92 marine engines seals the water tank or end-bell to the exchanger core. Saltwater exposure and vibration make this a periodic maintenance item.

Tips:

-

Neutralize salt deposits with appropriate cleaners; never gouge sealing lands.

-

Pressure-test the exchanger after reseal.

Raw Water Pump Mounting & Plate Gaskets

-

Mounting gasket: Seals the raw water pump to its mounting face.

-

Plate gasket: Seals the pump plate or cover; replace during impeller changes if disturbed.

Marine best practice: Whenever you pull the raw water pump for impeller service, keep a spare plate gasket on hand to guarantee a clean reseal.

Block Water Outlet & Water Manifold Sealing

A small but important block water outlet gasket seals the outlet and any block heater interface on some configurations. Replace if you see crusted coolant around the outlet.

Allison Marine Transmission Interface (Common 8V92 Turbo Pairings)

On many commercial and pleasure craft, the 8V92 Turbo is mated to Allison M and MH marine gears. Two flywheel housing gaskets (for SAE #1 and SAE #2) are used between the engine flywheel housing and the transmission’s bellhousing face.

Selection guidance:

-

Confirm your bellhousing size (SAE 1 or SAE 2). SAE 2 is most common in many 8V92 marine packages, but verify before ordering.

-

Inspect dowel alignment. A misaligned housing can create pump-drive wear in the marine gear and oil leaks at the interface.

Install tip: Clean both housings thoroughly, dry fit on dowels, then torque in a star pattern. A thin film of non-hardening sealant can help fill micro-porosity on older housings (use sparingly and only where appropriate).

Universal & Accessory Gaskets, Sealants, and Shop Supplies

General-Purpose Gaskets for 53/71/92 Series

You’ll see a few universal V-series gaskets in this section. While they list broader compatibility, they are fully appropriate for the 8V92 Turbo where specified (for example, certain inspection covers, manifold spacers, and flywheel covers). Treat these as 8V92-ready where the listing and geometry match your engine’s configuration.

Sealants & Adhesives: Where They Belong (and Don’t)

-

High-temp RTV (sensor-safe variants): Useful for stamped covers and non-exhaust joints that specify RTV in lieu of or in addition to a formed gasket. “Sensor-safe” types avoid harming engine-room sensors.

-

Non-hardening pliable sealant: Ideal for paper gaskets that need a tacky hold during assembly and easy future removal.

-

High-strength threadlocker (red): Reserve for fasteners that must not loosen (e.g., certain turbo studs). Use heat for removal later.

-

Gasket sprays (high-tack): Light coat on paper gaskets helps seating and prevents slippage on vertical faces.

-

Metal-filled epoxies (cold welds): For emergency field repairs on non-pressurized housings. Not a substitute for correct parts, but valuable for temporary stabilization.

Do not: Slather RTV or sealants on head gaskets, liner seals, or any joint where the OEM procedure prohibits it. Over-sealing can shed debris into oil and coolant passages and cause more harm than good.

Finishing Touch: Engine Paint

After a reseal, Detroit Green engine paint protects bare castings and refreshed housings from corrosion and salt spray. Paint also makes future leaks easier to spot—fresh oil on clean green paint shows immediately, speeding troubleshooting.

Selection Guide for the 8V92 Turbo: Make the Right Call the First Time

Rotation: Right-Hand vs. Left-Hand

Some 8V92 Turbo installations are right-hand rotation, others left-hand (commonly identified from the flywheel end).

What changes with rotation:

-

Front crank seals are rotation-specific.

-

Certain rear seals in newer styles are rotation-specific as well.

-

Universal rotation rear seals exist, but always check the listing and your engine build.

Standard vs. Oversize Seals

Use standard unless:

-

The crank seal journal shows wear grooves, and

-

You plan to install the rear seal sleeve and matching oversize rear seal.

Procedure note: Don’t press an oversize seal into a standard bore without the sleeve; you’ll either damage the lip or end up with a leaker.

Single-Lip vs. Double-Lip (Rear Seals)

-

Single-lip: Meets standard service needs with lower friction.

-

Double-lip: Adds a dust/exclusion lip—and is often favored in marine 8V92 Turbo service due to the environment. If your boat sees frequent spray or fine salt mist, a double-lip option is a smart pick.

Rocker Cover Gaskets: New-Style Gray vs. Kits

-

If your 8V92 Turbo uses aluminum rocker covers with later sealing rails, the new-style gray rubber gasket gives a clean reseal.

-

If fasteners, grommets, or rails are suspect, go with the complete rocker cover kit to refresh everything at once.

Marine Exhaust Connections: Match the Geometry

Marine manifolds, risers, spacers, and elbows vary by package builder. The gaskets in this section include:

-

Head-to-manifold

-

Marine flange and flange spacer patterns

-

JT-style variations

Always measure inner and outer dimensions and compare to your mating hardware. Heat-soaked manifolds can distort; if the flange isn’t flat, surface it before installing a fresh gasket.

Installation Best Practices for an 8V92 Turbo Reseal

Preparation & Surface Conditioning

-

Degrease thoroughly. Oil films destroy gasket seating. Acetone or a suitable brake-clean type solvent works well (observe safety).

-

Don’t gouge sealing lands. Use plastic scrapers; avoid Roloc-style abrasive discs on aluminum or deck surfaces where they can remove base metal.

-

Chase threads. Oil in blind holes can hydro-lock bolts and crack castings.

Dry Fits & Alignment

-

Exhaust and marine flanges: Dry fit manifolds, risers, and spacers to confirm bolt pattern alignment and that the gasket’s ports aren’t shrouded.

-

Flywheel housing & marine gear: Check dowels and runout; torque evenly to protect the gear’s pump drive.

Torque Patterns (General Guidance)

-

Head gaskets: Follow the factory sequence—typically center-out in stages. Never guess torque on V-bank heads; uneven crush guarantees early failure.

-

Manifolds & risers: Center-out, incremental steps; re-check after the first heat cycle if recommended.

-

Covers & pans: Lower torque values, even pattern. Over-torqueing bends rails and causes chronic weeping.

Sealant Strategy

-

Use only where specified. Head gaskets, liner seals, and most molded rubber gaskets are designed to seal dry or with assembly lube only.

-

High-temp jointing compound lives on turbo/exhaust interfaces that see extreme heat. Keep it off sensors and rotating parts.

-

Non-hardening sealant is excellent for paper gaskets where slight weep control is needed without bonding permanently.

First Start & Leak Check

-

Pre-lube if possible, especially after major reseals.

-

Run at fast idle and flashlight every seam: front cover, rear main area, oil cooler ends, turbo oil lines, head-to-manifold, marine flange joints, raw water pump, and heat exchanger bells.

-

After cool-down, re-inspect bolt torques where allowed.

Troubleshooting Common 8V92 Turbo Sealing Issues

Oil at the Bellhousing Weep Hole

Likely sources: rear main seal, flywheel housing gasket, or turbo return line dripping and tracking rearward.

Steps:

-

Clean the area and run briefly to identify the fresh trail.

-

If the crank journal is grooved, plan a rear seal sleeve + oversize seal.

-

Verify crankcase pressure; excessive blow-by can push oil past seals.

Oil Film Near the Front Damper

Likely source: front crank seal (ensure rotation-correct seal) or front end plate gasket.

Fix: Inspect damper sealing land; replace or repair as needed. Confirm the correct RH/LH front seal was used.

Sooty Streaks at Exhaust Manifold Ports

Likely source: failing head-to-manifold gaskets or warped manifold.

Fix: Resurface manifold, install fresh gaskets, torque to spec and re-check after a heat cycle.

Persistent Oil Mist in the Engine Room

Likely source: governor cover gaskets, rocker cover gaskets, or the flywheel housing cover.

Fix: Replace the small gaskets you disturbed during timing or rack adjustments; these are low-cost, high-return reseals.

Coolant Crusting at Water Manifold or Heat Exchanger

Likely source: water manifold gasket, heat-exchanger end-bell gasket, or raw-water pump plate gasket.

Fix: Strip, clean, and reseal. Pressure-test exchangers when practical.

Maintenance Intervals & Reseal Planning

-

After any major service: Replace any gasket or seal you disturbed. Reusing compressed paper gaskets usually leads to weeping.

-

Seasonal marine prep: Inspect turbo oil lines, marine exhaust gaskets, raw water pump plate gasket, and head-to-manifold joints. Replace at the first sign of seepage or streaking.

-

Overhaul window: Combine liner seals, head gasket kits (2 per 8V92), rocker cover gaskets, oil cooler gaskets, and front/rear mains into a single reseal plan. It’s more efficient than chasing individual leaks later.

Why Buy Your 8V92 Turbo Gaskets & Seals from Diesel Pro Power

-

Proven reliability, worldwide: Trusted by 40,000+ satisfied customers, Diesel Pro Power supports fleets, shipyards, and operators who depend on the 8V92 Turbo every day.

-

Marine-focused inventory: We stock the gaskets and seals that real 8V92 Turbo marine packages consume—head kits (two per engine), marine manifold and riser gaskets, turbo oil line gaskets, and flywheel housing gaskets for Allison M/MH pairings.

-

Fitment clarity: Product pages specify dimensions and engine rotation where relevant (RH/LH, single vs. double lip, standard vs. oversize). If you’re unsure, our team helps you match parts to your exact 8V92 Turbo build.

-

Fresh stock, fast shipping: In-stock items ship quickly, minimizing downtime. Packaging protects sensitive gaskets from creasing or contamination.

-

Bilingual support: English and Spanish assistance to help you verify parts, installation tips, and best practices.

-

Quality you can feel: From high-temp jointing compounds to sensor-safe RTV and non-hardening sealants, we stock the consumables that make reseals stick—and make disassembly easier next time.

-

Hassle-reduction guarantee: If something doesn’t look right when you open the box, contact us before you wrench—we’ll help you sort it out.

Quick Reference: What You’ll Use Most on an 8V92 Turbo

-

Head gasket kits: Two kits per 8V92 (one per bank).

-

Rocker cover sealing: New-style gray gaskets for aluminum covers or full kits if the hardware is tired.

-

Front & rear mains: Choose rotation-specific front seals; choose single- or double-lip rear seals, standard or oversize with sleeve as required.

-

Blower install kit (turbo): Mandatory after blower work on a turbocharged 8V92.

-

Turbo interfaces: Riser gasket plus oil supply/return gaskets; consider high-temp jointing compound on exhaust flanges.

-

Marine exhaust gaskets: Head-to-manifold, flange, spacers, and JT-type patterns as your manifold/riser package requires.

-

Cooling & oiling: Oil cooler gaskets (and the double-cooler kit where applicable), heat exchanger gasket, raw-water pump mounting/plate gaskets, and block water outlet gasket.

-

Transmission interface: SAE #1 or #2 flywheel housing gaskets to pair with Allison M/MH marine gears.

Pro Installation Tips for Long-Lasting Seals

-

Measure twice, seal once: Confirm rotation, seal size, and gasket geometry before teardown ends.

-

Flatness is king: Use a straightedge on manifolds, risers, and housings; resurface or replace warped parts.

-

Clean, dry, aligned: Most gaskets prefer dry, clean faces; apply sealant only where procedures specify.

-

Torque by the book: Step-torque and sequence patterns prevent uneven crush.

-

Heat-cycle checks: After first run, cool down and re-verify torque where allowed, especially on exhaust joints.

-

Document everything: Record liner protrusion, torque values, and leak checks. Good notes save hours later.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588