Parts for Caterpillar 3208 Non Turbo for Australia - Crankshaft Section

Loading...

Loading... Parts for Caterpillar 3208 Non-Turbo – Crankshaft Section

The crankshaft system is at the heart of every Caterpillar 3208 non-turbo engine. It transforms the up-and-down movement of the pistons into rotational energy, which powers marine vessels, industrial pumps, and stationary generators. For operators who depend on the Caterpillar 3208, maintaining the crankshaft and its supporting components—bearings, seals, thrust washers, and vibration dampers—is essential for reliability and performance.

At Diesel Pro Power, we provide a complete range of crankshaft parts engineered specifically for the Caterpillar 3208 natural aspiration engine. Our catalog covers everything from new crankshafts to precision-fit bearings in multiple sizes, as well as seals, washers, and dampers designed for long-lasting service in marine and industrial duty.

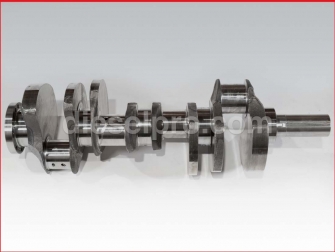

Crankshaft for Caterpillar 3208 Non-Turbo Engines

The crankshaft is the central rotating component of the Caterpillar 3208. Machined from high-strength steel, it is built to withstand extreme pressures and torque while maintaining balance and smooth motion. A new crankshaft restores the rotating assembly to original factory tolerances, helping to reduce vibration, prevent premature bearing wear, and extend the life of the engine.

Applications include:

-

Fishing vessels and commercial boats powered by the 3208.

-

Industrial generators requiring dependable rotational power.

-

Heavy-duty pumps and compressors.

When replacing a crankshaft, it is always recommended to install new bearings, seals, and thrust washers to ensure optimal fit and alignment.

Vibration Damper for Caterpillar 3208 Non-Turbo

A vibration damper, sometimes referred to as a harmonic balancer, is mounted at the front of the crankshaft. Its role is to absorb torsional vibrations created as the pistons fire. Without a functioning damper, the crankshaft could experience dangerous harmonic resonance, leading to cracks or catastrophic failure.

Key benefits:

-

Reduces harmful vibrations and engine noise.

-

Extends the life of the crankshaft and connected components.

-

Ensures smoother operation under heavy loads common in marine and industrial use.

Replacing the damper at regular overhaul intervals helps preserve the structural integrity of the crankshaft.

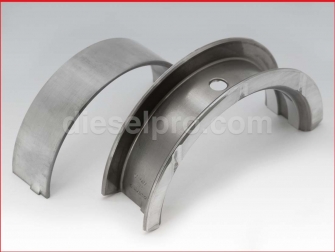

Main Bearings for Caterpillar 3208

Main bearings provide the smooth interface between the crankshaft and engine block. These precision-engineered components support the rotating crankshaft, allowing it to spin freely while carrying the massive forces of combustion.

Diesel Pro Power offers standard and oversize main bearings for the 3208, ensuring operators can choose the right fit based on crankshaft and block condition. Oversize options are particularly important when regrinding a crankshaft journal to restore roundness and smoothness.

Standard Main Bearings

Designed for blocks and crankshafts still within factory specifications. Standard bearings are installed during regular maintenance or complete rebuilds when no machining adjustments are required.

Oversize Main Bearings

Available in multiple oversize increments (.010, .020, .050), these bearings are essential when the crankshaft journals have been ground down during machining. Each oversize restores the correct oil clearance, ensuring proper lubrication and load distribution.

By matching the bearing size precisely, operators prevent excessive wear, oil starvation, and overheating of the crankshaft journals.

Thrust Bearings for Caterpillar 3208

Thrust bearings play a critical role in controlling axial movement of the crankshaft. In the Caterpillar 3208, they prevent forward or backward shifting caused by the helical motion of the transmission gears or heavy axial loads.

Standard Thrust Bearings

Used when the crankshaft and block remain within factory specifications. They maintain proper endplay and prevent damage to the block and rotating assembly.

Oversize Thrust Bearings

Offered in increments (.010, .020, .050), oversize thrust bearings restore crankshaft endplay tolerance after machining or wear. Choosing the correct oversize ensures smooth gear engagement, reduced stress on the transmission, and extended service life.

Bearing #1 Grooved for Caterpillar 3208

The #1 grooved bearing in the Caterpillar 3208 series is designed for specific block applications and provides enhanced lubrication to critical areas. By directing oil through its precision grooves, this bearing ensures stable oil flow to the crankshaft’s leading journal.

Operators should always verify block compatibility before selecting a grooved bearing, as certain block numbers require specialized fitment.

Thrust Washers for Caterpillar 3208 Crankshaft

Thrust washers complement the thrust bearing by fine-tuning axial control of the crankshaft. They are installed in pairs and come in different thicknesses to achieve precise endplay.

Replacing worn thrust washers prevents crankshaft walk, which could otherwise damage bearings, gears, or seals.

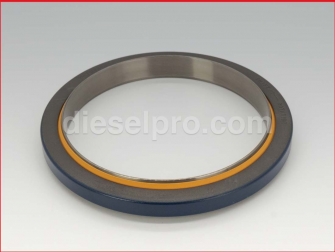

Crankshaft Seals for Caterpillar 3208

Seals ensure that oil remains inside the engine while keeping contaminants out. For the Caterpillar 3208, both front and rear seals are critical in preventing oil leaks that can compromise performance and environmental safety.

Front Crankshaft Seal

Located at the pulley end of the crankshaft, this seal prevents oil from escaping the timing cover. A new front seal is typically installed during crankshaft service or overhaul to protect against leaks under continuous operation.

Rear Crankshaft Seal

Mounted where the crankshaft connects to the flywheel housing, the rear seal prevents oil leaks that could contaminate the clutch or transmission. Because this area is difficult to access, it is advisable to replace the rear seal whenever the engine is dismantled for service.

Importance of Proper Fitment and Sizing

Selecting the right size and type of bearings or washers is critical for crankshaft longevity. Too much clearance can lead to oil starvation and bearing knock, while too little clearance creates excessive friction and heat. Operators should:

-

Measure crankshaft journals carefully with micrometers during rebuilds.

-

Check block housing bores to confirm alignment.

-

Use plastigauge or clearance measurement tools to ensure proper oil film thickness.

-

Select the correct oversize based on machining work performed.

By following these steps, marine and industrial operators can restore their Caterpillar 3208 engines to peak performance.

Marine and Industrial Applications

The Caterpillar 3208 has powered vessels, gensets, and equipment for decades. The crankshaft system is particularly important in these contexts:

-

Marine Engines: Continuous-duty service demands smooth, balanced crankshaft operation to handle long voyages and heavy propeller loads.

-

Generators: Stable rotational energy is required to produce consistent electrical output. Any crankshaft imbalance could affect power quality.

-

Pumps and Compressors: Industrial machinery powered by the 3208 relies on the crankshaft to deliver consistent torque without interruption.

Maintaining crankshaft components is critical for these high-demand applications.

Why Choose Diesel Pro Power for Caterpillar 3208 Crankshaft Parts

When it comes to sourcing crankshaft components for the Caterpillar 3208, operators worldwide trust Diesel Pro Power for unmatched support, quality, and availability. Whether you are maintaining a vessel, overhauling a generator, or rebuilding an industrial engine, we deliver the right parts when you need them.

-

Global Shipping: Orders ship within 24 hours to more than 180 countries, ensuring your equipment stays operational with minimal downtime. Our streamlined logistics process is designed for both marine and industrial operators who cannot afford delays.

-

Proven Experience: With more than 40,000 satisfied customers worldwide, Diesel Pro Power has earned a reputation for reliability. Our experience translates into practical support—helping you identify the right crankshaft parts, even across variations of the 3208 natural and turbocharged engines.

-

Comprehensive Coverage: From crankshafts and vibration dampers to main bearings, seals, and washers, everything needed to service the rotating assembly of your Caterpillar 3208 is available in one centralized catalog. This eliminates the hassle of searching multiple suppliers and ensures every part works together seamlessly.

-

Expert Guidance: Our knowledgeable team goes beyond simply supplying parts. We help ensure compatibility with your exact Caterpillar 3208 configuration, advising on standard vs. oversize bearings, matching seals to your crankshaft design, and guiding you through best practices for installation.

-

Marine & Industrial Focus: Unlike general suppliers, Diesel Pro specializes in heavy-duty engines built for continuous operation under demanding conditions. Every crankshaft component we provide is engineered for reliability in the toughest marine environments and industrial applications.

By choosing Diesel Pro Power, you’re not just buying crankshaft parts—you’re gaining a trusted partner that ensures your Caterpillar 3208 engine remains dependable for years to come.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588