Parts for Caterpillar 3208 Non Turbo for Australia - Oil Section

Loading...

Loading... Caterpillar 3208 Non-Turbo Engine Oil System Parts Catalog

The Caterpillar 3208 natural (non-turbo) engine is renowned for its durability and long service life in both marine and industrial applications. A critical factor in achieving this reliability is proper lubrication. The oil system ensures that every moving component—from bearings to pistons—is adequately lubricated, cooled, and protected from wear. At Diesel Pro Power, we provide a full range of oil system components for the Caterpillar 3208 natural and turbocharged engines, ensuring peak performance and extended engine life.

Below you will find an expanded catalog of Caterpillar 3208 oil system parts, along with detailed explanations of each component’s role, application tips, and maintenance best practices.

Oil Filters for Caterpillar 3208 Engines

Oil Filter (Advanced Efficiency Design)

The oil filter is the first line of defense against harmful contaminants that can circulate through the lubrication system. For Caterpillar 3208 engines, we supply filters engineered for both natural and turbocharged versions, offering advanced efficiency to capture even the smallest debris. These filters maintain proper oil flow while reducing wear on bearings, pistons, and camshafts.

Key Benefits:

-

Prevents premature wear of internal engine parts.

-

Extends oil life by reducing contamination.

-

Designed to meet Caterpillar OEM specifications.

Maintenance Tip: Replace the oil filter at every scheduled oil change to prevent bypass conditions and ensure the engine always runs on clean oil.

Oil Pumps and Related Components

Oil Pump (Gear-Driven, 38 Teeth)

The heart of the lubrication system is the oil pump. In the 3208, a gear-driven pump ensures steady oil pressure and consistent flow across all operating conditions. The 38-tooth design is optimized for this engine, ensuring balance between flow rate and pressure.

Why It Matters:

Without proper oil pressure, bearings and pistons quickly overheat, leading to catastrophic damage. A high-quality pump ensures reliability even under heavy marine loads or continuous industrial duty.

Cover Assembly for Oil Pump

The cover assembly seals and protects the pump gears. Maintaining a proper fit prevents oil leaks and ensures the pump maintains suction.

Oil Pump Guide

This component helps align and stabilize the oil pump during operation. A worn guide can lead to vibration or misalignment, reducing pump efficiency.

Oil Pump Bearing Sleeve

The sleeve reduces friction between the pump shaft and housing. Over time, wear on this sleeve can cause oil pressure loss. Replacing it during rebuilds helps maintain system integrity.

Oil Pressure Control Components

Oil Relief Valve Spring

Regulates the maximum oil pressure to protect seals and gaskets from over-pressurization.

Plunger Relief Valve

Works with the spring to modulate pressure, opening when oil pressure exceeds safe limits.

Relief Valve O-Ring Seal

A small but critical component, this O-ring prevents leaks around the relief valve assembly. Even minor leaks can reduce oil pressure and starve components of lubrication.

Maintenance Tip: If you observe fluctuating or consistently low oil pressure, inspect the relief valve components and O-rings for wear.

Oil Coolers and Gaskets

Oil Cooler Cores

The 3208 engine relies on oil coolers to maintain safe operating temperatures. Overheated oil loses viscosity and cannot properly lubricate moving parts. Diesel Pro Power offers cooler cores for both early and later engine serial prefixes.

Compatibility Notes:

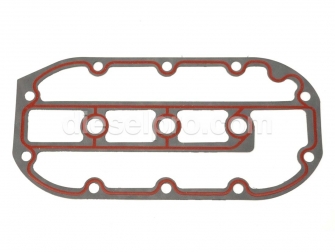

Oil Cooler Gaskets

Essential for sealing cooler assemblies to prevent oil leaks and cross-contamination with coolant. Available for both 75V and 1Z1 engines. Always replace gaskets when installing a new core or servicing the cooler.

Tip for Marine Operators: Oil cooler failure is one of the most common causes of overheating in marine diesel engines. Inspect for leaks or corrosion at every service interval.

Oil Filter Bases and Pans

Oil Filter Base

The filter base holds the oil filter securely in place while channeling oil through the filtration system. A damaged or cracked base can lead to leaks and poor oil circulation.

Oil Pan Gasket

Seals the oil pan to the engine block. Even small leaks at the pan gasket can cause gradual oil loss, risking lubrication failure during extended runs. Marine and industrial operators should check for leaks frequently due to vibration and thermal expansion stresses.

Tools for Oil System Maintenance

Oil Filter Removal Wrench

A universal tool compatible with Caterpillar, Cummins, and Detroit Diesel engines. Designed for filters between 4-21/32" and 5-5/32", this wrench provides the leverage needed to remove stubborn or overtightened filters without damaging the housing.

Pro Tip: Always lubricate the new filter’s O-ring with fresh oil before installation to prevent sticking and make removal easier next service.

Importance of Regular Oil System Maintenance

Proper lubrication is the foundation of Caterpillar 3208 engine longevity. Marine and industrial operators who follow strict oil change schedules, replace filters consistently, and monitor oil pressure will benefit from:

-

Reduced downtime from unexpected failures.

-

Lower long-term operating costs.

-

Improved reliability under heavy duty cycles.

Why Choose Diesel Pro Power for Caterpillar 3208 Oil System Parts

Choosing the right supplier for Caterpillar 3208 oil system components is as important as the parts themselves. Diesel Pro Power delivers:

-

Global Reach: Fast shipping to more than 180 countries.

-

Proven Trust: Over 40,000 satisfied customers worldwide.

-

Comprehensive Inventory: From oil pumps to O-rings, everything for the 3208 is available in one place.

-

Expert Support: Our team ensures correct part selection for your specific serial prefix and setup.

-

Marine & Industrial Focus: Unlike general suppliers, Diesel Pro Power specializes in engines designed for continuous duty in demanding environments.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588