Parts for Caterpillar 3208 Turbo for Australia - Oil Section

Loading...

Loading... Parts for Caterpillar 3208 Turbo – Oil System Section

The lubrication system of the Caterpillar 3208 Turbo engine is central to its performance and longevity. Proper oil circulation reduces friction, prevents overheating, minimizes wear on moving parts, and ensures the engine can perform under continuous load in marine and industrial environments. In this section, you will find every critical component of the 3208 oil system, from filters and pumps to coolers, relief valves, and gaskets. Each item is engineered to match Caterpillar specifications, ensuring dependable performance for both natural and turbocharged variants of the 3208.

With more than 40,000 satisfied customers worldwide, Diesel Pro Power supplies genuine and aftermarket components that are proven in the field. Whether you are preparing for a major overhaul, replacing a worn component, or conducting preventive maintenance, this catalog provides the comprehensive coverage you need to keep your Caterpillar 3208 running at peak condition.

Oil Filtration Components for Caterpillar 3208 Turbo

Advanced Efficiency Oil Filter

The oil filter is the first line of defense against contaminants. In the 3208 engine, an advanced efficiency filter traps microscopic particles, soot, and debris that circulate through the system. Over time, oil picks up carbon deposits and metallic fragments that, if left unchecked, can score bearings, wear journals, and shorten engine life.

High-efficiency filters designed for the Caterpillar 3208 maintain consistent flow while providing superior filtration. The large surface area of the filter media ensures maximum dirt-holding capacity, which is essential in heavy-duty marine and industrial applications where oil change intervals may be extended. Regular replacement of the filter ensures reliable lubrication and helps protect high-value components like the crankshaft, camshaft, and turbocharger.

Oil Pump Assembly and Related Parts

Main Oil Pump

The oil pump is the heart of the lubrication system. In the Caterpillar 3208 Turbo, a precision-engineered gear-type pump with 38 teeth ensures constant oil flow under varying loads and RPM ranges. By drawing oil from the sump and distributing it through galleries, the pump maintains film strength between bearings and moving parts.

A worn or inefficient pump can lead to low oil pressure, which is catastrophic for an engine under load. Replacing the pump during an overhaul or when signs of pressure loss appear is critical to prevent bearing failure, piston seizure, or turbo damage.

Oil Pump Cover Assembly

The cover assembly secures the gears and maintains the proper clearances within the pump housing. A compromised cover can result in oil leakage or pressure loss. Precision-machined replacements are available to restore the pump’s original performance characteristics.

Oil Pump Guide

This small but vital component ensures alignment and smooth operation of the pump gears. Even minor wear in the guide can cause efficiency loss or accelerated wear on the pump. Replacing the guide during servicing helps extend the life of the oil pump.

Oil Pump Bearing Sleeve

The bearing sleeve reduces friction within the pump and ensures smooth gear rotation. Sleeves that show scoring or excessive play can cause noise, reduced pressure, and eventual pump failure. Replacements are designed for exact fit and durability under high load conditions.

Oil Pressure Regulation Components

Oil Relief Valve Spring

The relief valve spring regulates oil pressure within the system. Too much pressure can cause leaks, while too little can starve components. Over time, springs weaken from heat cycles and continuous operation. Installing a fresh spring restores proper tension and pressure regulation.

Oil Relief Valve Plunger

Working in tandem with the spring, the plunger moves to bypass excess oil when pressure exceeds the designed limit. A worn or sticking plunger can lead to pressure spikes or drops, both of which endanger the engine. Replacement plungers are precision-ground to restore smooth operation.

O-Ring Seal for Relief Valve

To prevent leaks at the relief valve seat, a properly fitting O-ring is essential. A hardened or cracked O-ring can allow bypass leakage, reducing pressure in the system. Quality replacements are available to ensure a proper seal and consistent performance.

Oil Cooling Components for Caterpillar 3208 Turbo

Oil Cooler Cores

Oil coolers are critical in marine engines where high loads and limited airflow create elevated oil temperatures. For the Caterpillar 3208 Turbo, two main types of cooler cores are available, each designed for specific engine serial prefixes. These cores transfer heat from the oil into coolant, maintaining optimal operating temperatures and preventing viscosity breakdown.

Engines with the 75V prefix require one version of the core, while those with 1Z1 prefix serials use another. Installing the correct core for your serial series ensures proper fit and maximum efficiency. Regular inspection of cooler cores is advised, as internal clogging or corrosion can lead to overheating and accelerated wear.

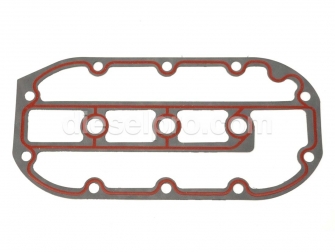

Oil Cooler Gaskets

Every cooler core must be paired with high-quality gaskets to prevent cross-contamination of oil and coolant. Two gasket styles are available for the 3208, matched to specific serial prefixes. Gaskets should always be replaced during cooler servicing to avoid leaks that can compromise the entire lubrication and cooling system.

Oil Filter Base and Related Components

Oil Filter Base

The filter base provides the mounting platform for the spin-on oil filter. It includes passages for oil flow and ports for pressure monitoring. A damaged or corroded base can cause leakage or improper filter sealing. Replacement bases restore reliability and ensure secure filter installation.

Oil Filter Removal Tool

To simplify maintenance, an oil filter removal wrench is available for the 3208. This tool is compatible with Caterpillar filters as well as filters used on Detroit Diesel and Cummins engines. Adjustable in range, it provides the leverage needed to remove filters without damaging the housing.

Oil Pan and Sealing Components

Oil Pan Gasket

The oil pan gasket seals the sump against the engine block, preventing leaks and maintaining oil capacity. Over time, gaskets can harden, crack, or compress unevenly, leading to drips and reduced oil levels. Replacing the gasket during pan removal or overhaul ensures a leak-free seal.

Importance of Maintaining the Caterpillar 3208 Oil System

The Caterpillar 3208, whether in natural or turbocharged form, is designed for continuous operation in marine vessels, generators, and heavy equipment. Because these engines often run for extended periods under heavy load, oil system integrity is paramount.

Key reasons for maintaining the oil system include:

-

Lubrication of Bearings and Journals – Preventing metal-to-metal contact.

-

Heat Dissipation – Carrying heat away from pistons, bearings, and turbo components.

-

Contaminant Removal – Trapping dirt and carbon particles in the filter.

-

Pressure Regulation – Ensuring optimal film strength across operating ranges.

-

Longevity – Extending the service life of high-value components like the crankshaft and camshaft.

Why Choose Diesel Pro Power for Caterpillar 3208 Oil System Parts

Operators around the world turn to Diesel Pro Power for reliable Caterpillar 3208 parts because of our proven advantages:

-

Global Shipping – Fast delivery to over 180 countries, with most orders shipped within 24 hours.

-

Proven Experience – More than 40,000 satisfied customers worldwide.

-

Comprehensive Catalog – Every oil system component in one place: filters, pumps, gaskets, seals, tools, and coolers.

-

Expert Support – Our technical team ensures the correct match for your exact 3208 configuration, whether natural or turbocharged.

-

Marine and Industrial Focus – We specialize in engines designed for continuous duty in demanding environments, not light-duty or automotive applications.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588