Parts for Caterpillar 3406C for Australia - Crankshaft Section

Loading...

Loading... Parts for Caterpillar 3406C – Crankshaft Section

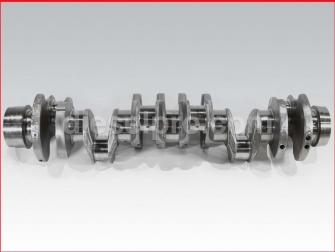

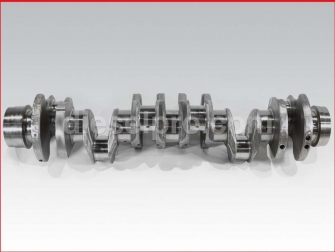

The crankshaft system is one of the most vital assemblies in any Caterpillar 3406C engine. It converts the linear motion of pistons into the rotary motion that powers heavy-duty trucks, marine vessels, construction equipment, and industrial power generators. A properly functioning crankshaft and its related components ensure smooth engine operation, balanced performance, and long service life.

At Diesel Pro Power, we specialize in supplying premium aftermarket crankshaft parts designed to meet or exceed Caterpillar performance standards. Our inventory includes brand-new crankshafts, main bearings in standard and oversize specifications, thrust washers, vibration dampers, gears, dowel pins, and front and rear crankshaft seals. Each component is carefully manufactured for reliability, precision fit, and long-term durability under the toughest working conditions.

Caterpillar 3406C Crankshaft Overview

The crankshaft is the backbone of the 3406C engine. It endures extreme pressures and rotational forces as it transfers combustion energy into usable torque. The 3406C crankshaft is a forged steel component designed for heavy-duty applications, ensuring maximum strength while minimizing flex and wear.

The crankshaft works in concert with the main bearings, thrust washers, vibration dampers, and gears to maintain proper balance and timing within the engine. Seals and dowel pins provide additional support, preventing oil leaks and ensuring components remain precisely aligned.

Diesel Pro Power offers both wide bearing and narrow bearing designs for Caterpillar 3406 engines, allowing operators to match the correct crankshaft type for their engine serial number or rebuild specification.

Crankshafts for Caterpillar 3406C

Wide Bearing Design Crankshaft

The wide bearing crankshaft is engineered for specific applications within the 3406 engine family. Wide bearing designs offer enhanced load distribution, which reduces wear under high torque conditions. They are especially common in heavy hauling and industrial applications where the engine runs at higher loads for prolonged periods.

Narrow Bearing Design Crankshaft

The narrow bearing crankshaft is another variation used in many Caterpillar 3406C engines. While slightly different in configuration, it provides the same level of strength and durability, offering operators flexibility when selecting replacement components for their rebuild. Narrow bearing crankshafts are often chosen when weight balance and precise fitment for particular engine configurations are required.

Main Bearings for Caterpillar 3406C

Main bearings support the crankshaft within the engine block, allowing it to rotate smoothly while minimizing metal-to-metal contact. The bearings must endure enormous pressure while also maintaining a thin film of lubrication to prevent friction and heat buildup.

Standard Size Main Bearings

Standard size bearings are used when the crankshaft journal surfaces remain within original factory specifications. These are common in engines where the crankshaft has not required regrinding.

Oversize Bearings

When crankshafts undergo regrinding during a rebuild, oversize bearings are installed to ensure proper clearance. Diesel Pro Power supplies oversize bearings in increments such as .010", .025", and .050", allowing rebuilders to match exact specifications. Using the correct oversize bearing ensures long-term reliability and proper oil film thickness for lubrication.

Thrust Washers for Caterpillar 3406C

The thrust washer plays a critical role in controlling axial movement of the crankshaft. Without thrust washers, the crankshaft could shift forward or backward, causing misalignment and severe engine damage. Two thrust washers are used per engine, ensuring that the crankshaft remains centered under varying loads.

Diesel Pro Power provides durable, precisely machined thrust washers designed to handle the demanding environments in which 3406C engines operate.

Vibration Damper for Caterpillar 3406C

High-powered diesel engines like the 3406C generate torsional vibrations as combustion events occur in each cylinder. The vibration damper—sometimes called a harmonic balancer—absorbs these vibrations, protecting the crankshaft and connected components from fatigue and failure.

A worn or failing damper can lead to premature crankshaft wear, broken components, and catastrophic engine failure. Replacing the vibration damper during a crankshaft overhaul ensures long-term engine stability.

Crankshaft Gears for Caterpillar 3406C

The crankshaft gear drives essential timing components in the engine, including the camshaft and accessory systems. A properly machined gear with the correct tooth count ensures precise timing, efficient combustion, and reliable power delivery.

Diesel Pro Power offers replacement crankshaft gears specifically designed for the Caterpillar 3406 engine family. Each gear is engineered for accurate fit, smooth operation, and long service life.

Crankshaft Dowel Pins

Dowel pins may appear small, but they are vital in maintaining precise alignment between the crankshaft and the crankshaft gear. Without proper dowel pin engagement, timing can slip, leading to misfires, loss of power, or catastrophic engine damage.

Diesel Pro Power supplies hardened steel dowel pins manufactured to exact specifications, ensuring reliable gear alignment in the Caterpillar 3406C.

Crankshaft Seals for Caterpillar 3406C

Front Crankshaft Seal

The front crankshaft seal prevents oil from escaping at the front end of the engine, near the timing gear housing. A reliable front seal ensures the lubrication system maintains proper oil levels while keeping contaminants out.

Rear Crankshaft Seal

The rear crankshaft seal performs a similar function at the back of the engine, near the flywheel. Rear seal failure often leads to significant oil leaks that can cause engine shutdowns if not addressed.

Diesel Pro Power offers both front and rear crankshaft seals designed with durable materials to withstand extreme heat, pressure, and vibration.

Importance of a Complete Crankshaft Rebuild

When performing a rebuild on the Caterpillar 3406C, it’s critical to replace not only the crankshaft but also the supporting components—bearings, thrust washers, seals, and dampers. Reusing worn parts can lead to premature failure, even if a new crankshaft is installed.

By sourcing all components together, operators can ensure:

-

Precise alignment and fit

-

Proper lubrication clearance

-

Elimination of oil leaks

-

Protection against vibration and torsional stress

-

Extended engine life and reliability

Applications of the Caterpillar 3406C

The Caterpillar 3406C engine is renowned for its versatility and durability across industries. Common applications include:

-

Trucking: Long-haul trucks, dump trucks, and vocational vehicles.

-

Marine: Fishing vessels, tugboats, and workboats.

-

Construction: Excavators, bulldozers, and cranes.

-

Industrial Power: Generators and pumps in remote operations.

-

Mining: Haul trucks, loaders, and drilling equipment.

Each of these industries demands maximum uptime. That’s why operators worldwide trust Diesel Pro Power for crankshaft system components that ensure their Caterpillar 3406C engines remain reliable in the most demanding environments.

Why Choose Diesel Pro Power for Caterpillar 3406C Crankshaft Parts

-

Trusted by 40,000+ Customers Worldwide – Serving operators across 180+ countries, Diesel Pro Power is the go-to source for Caterpillar engine parts.

-

Premium Aftermarket Quality – Every crankshaft, bearing, washer, gear, and seal is manufactured to exacting standards, ensuring durability and precise fit.

-

Fast Worldwide Shipping – With global logistics expertise, we deliver quickly to minimize downtime.

-

Dedicated Caterpillar 3406C Catalog – Parts are organized by engine system, making it easy to locate and order exactly what you need.

-

Expert Technical Support – Our specialists guide operators through rebuild decisions, helping them select wide vs. narrow bearing crankshafts, proper oversize bearings, and correct installation procedures.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588