Parts for Caterpillar 3408B for Australia - Cylinder Head Section

Loading...

Loading... Caterpillar 3408B Cylinder Head Parts Catalog

The Caterpillar 3408B is one of the most respected V8 diesel engines in Caterpillar’s 3400 Series, designed for continuous-duty marine, industrial, and heavy equipment applications. At the heart of this engine’s performance lies the cylinder head assembly—a critical component that houses the intake and exhaust valves, precombustion chambers, valve springs, and all related sealing hardware. This section of the catalog provides an in-depth look at every cylinder head component available for the Caterpillar 3408B, ensuring that marine operators, industrial users, and service technicians can source every part required for maintenance, repair, or a complete top-end rebuild.

With over 40,000 satisfied customers worldwide, Diesel Pro Power is the trusted supplier for Caterpillar cylinder head components, shipping quickly to more than 180 countries. Whether you need a bare replacement head, a fully assembled unit with valves and springs, or supporting hardware such as gaskets, bolts, washers, and valve guides, you will find everything you need in this catalog.

Complete Cylinder Heads for Caterpillar 3408B

Bare Cylinder Heads

Bare cylinder heads are ideal for shops and operators who want to customize or reuse existing hardware. Supplied without valves or springs, these heads provide a solid foundation for a rebuild. Each casting is designed for precombustion chamber engines used in the 3408B platform, ensuring correct fitment and long-term durability under heavy loads.

Cylinder Heads with Valves and Springs

For operators who prefer a ready-to-install option, fully assembled cylinder heads with valves and springs offer a streamlined solution. These units are built to OEM specifications, providing consistent airflow, precise seating, and reliable valve operation. Using a preassembled head reduces installation time and helps ensure that new components are matched correctly, minimizing downtime.

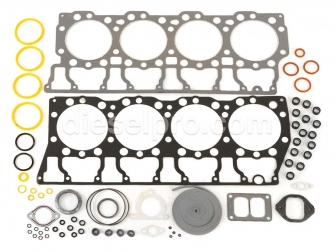

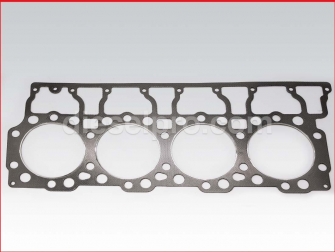

Cylinder Head Gasket Sets

Cylinder head gaskets form the critical seal between the block and head. For the Caterpillar 3408B, gasket sets are supplied with all necessary sealing components to service both banks of the V8 design. Two gaskets are required per engine.

These gaskets are engineered to handle the high compression ratios of the 3400 Series while resisting combustion gas leakage and coolant/oil cross-contamination. They are suitable for engines carrying arrangement numbers and serial prefixes such as 1LG, 8RG, and 99U, making them compatible with a wide range of Caterpillar 3408B installations.

Cylinder Head Bolts and Washers

Proper clamping force is essential for cylinder head performance. The Caterpillar 3408B uses specialized 12-point head bolts as well as conventional high-tensile bolts in different lengths and thread specifications. These bolts ensure that the cylinder head gasket is compressed evenly, preventing leaks and maintaining combustion efficiency.

Head Bolt Washers

Washers provide even load distribution across the cylinder head surface. Using new washers during installation prevents bolt galling and reduces the risk of uneven torque, especially important in engines that see high continuous-duty operation.

Intake and Exhaust Valves

The cylinder head’s ability to breathe depends on high-quality intake and exhaust valves. For the Caterpillar 3408B:

-

Intake valves are designed for cool, efficient airflow, ensuring the engine draws in the right amount of oxygen for combustion.

-

Exhaust valves withstand extreme heat, directing burnt gases out of the chamber.

Both valve types are available for multiple Caterpillar arrangements, ensuring compatibility across a wide range of 3408B configurations. Precision-ground valve faces and hardened stems increase service life in high-load applications.

Rotocoils and Valve Hardware

Rotocoil Assemblies

Rotocoils play a crucial role in valve longevity by slowly rotating valves during operation. This prevents hot spots from forming on the valve face, reduces wear, and ensures uniform seating. The Caterpillar 3408B uses both single-spring rotocoil assemblies and individual rotocoils for precombustion chamber engines.

Valve Guides

Guides maintain precise alignment of valves within the cylinder head. Options are available for both precombustion and direct injection Caterpillar engines, ensuring smooth valve travel and extended component life.

Valve Inserts (Seats)

Both intake and exhaust valve inserts are available. These hardened seats provide a replaceable surface for the valves to seal against, critical in extending the service life of the cylinder head casting itself. Proper installation ensures resistance to heat, pitting, and gas erosion.

Valve Springs

High-tension valve springs control the opening and closing of valves under the stresses of high-RPM operation. For the Caterpillar 3400 Series engines, both intake and exhaust springs are offered, maintaining valve timing integrity and preventing valve float.

Valve Locks

Valve locks secure the springs and retainers, ensuring valves remain in position under dynamic loads. Since two locks are required per valve, it is recommended to replace them during any major head service.

Precombustion Chambers and Related Seals

The Caterpillar 3408B operates with precombustion chamber technology, which requires specialized components to ensure proper fuel ignition and chamber sealing.

-

Precombustion chambers themselves are available for replacement in worn or damaged heads.

-

Sealing O-rings, gaskets, and washer seals are included to maintain airtight integrity and prevent coolant or combustion gas leaks.

-

Each chamber uses one gasket and one washer seal, both of which should be replaced during any top-end service.

Maintaining this system ensures proper fuel atomization, smooth combustion, and reliable cold-start performance.

Push Rods and Valve Lifters

Push Rods

Push rods transfer motion from the camshaft and lifters to the rocker arms, opening and closing the valves in sequence. Heavy-duty push rods designed for Caterpillar 3408B engines ensure reliable performance under constant stress.

Valve Lifters

Also known as tappets, lifters maintain proper contact between the camshaft and push rods. Precision machining ensures reduced friction and consistent valve timing.

Why Cylinder Head Service Matters

Cylinder head maintenance is one of the most critical aspects of keeping a Caterpillar 3408B in peak condition. Symptoms of cylinder head issues may include:

-

Loss of compression or power

-

Coolant leakage into combustion chambers

-

Burnt or pitted valves

-

Excessive smoke due to improper combustion

Timely replacement of gaskets, valves, or complete heads can prevent catastrophic engine damage and extend the life of the 3408B engine in marine vessels, generators, or industrial equipment.

Why Choose Diesel Pro Power for Caterpillar 3408B Cylinder Head Parts

When investing in cylinder head components, the supplier you choose is just as important as the part itself. Diesel Pro Power stands apart by offering:

-

Global Shipping – Fast delivery to over 180 countries.

-

Proven Reliability – More than 40,000 satisfied customers worldwide.

-

Comprehensive Coverage – From complete heads to valve locks, every component is available in one catalog.

-

Marine & Industrial Focus – Unlike automotive suppliers, Diesel Pro specializes in continuous-duty applications.

-

Expert Support – Our team assists in identifying the correct cylinder head, gasket set, or hardware for your specific Caterpillar 3408B arrangement.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588