Parts for Caterpillar 3412C for Australia - Gasket Section

Loading...

Loading... Caterpillar 3412C Overhaul Gasket Section

The Caterpillar 3412C is one of the most powerful and reliable V12 engines produced by Caterpillar, built for demanding applications in marine propulsion, oilfield operations, mining, power generation, and heavy industrial machinery. To maintain this engine’s legendary durability, a complete set of high-quality gaskets is essential for every in-frame repair, overhaul, or top-end rebuild.

This section highlights the gasket sets and individual sealing components available for the 3412C, ensuring operators have access to the precise parts required to restore engine efficiency and prevent leaks.

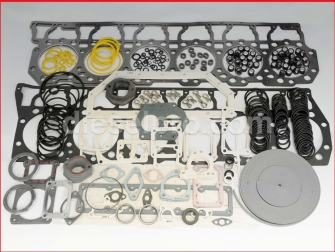

Complete Overhaul Gasket Sets for Caterpillar 3412C

In-Frame Repair Gasket Set

The in-frame repair gasket set is designed for mid-life service work where the engine remains in the block but requires extensive resealing. This set includes essential gaskets for cylinder heads, liners, oil seals, and supporting components. It allows operators to address wear points such as combustion chamber sealing, oil pan leaks, or coolant system seepage without fully removing the engine.

Key Benefits:

-

Covers critical sealing components for partial rebuilds

-

Reduces downtime with a single, consolidated package

-

Ensures compatibility with the 3412C as well as earlier variants like the 3412 and 3412B

Cylinder Head Gasket Set

The cylinder head gasket set is essential when replacing or resurfacing cylinder heads. For the Caterpillar 3412C, each engine requires two heads, and this kit provides the necessary gaskets to ensure a secure seal between the head and the block.

Key Benefits:

-

Designed for precise sealing under high combustion pressure

-

Prevents oil and coolant cross-contamination

-

Supports both standard and high-load operating conditions

Complete Overhaul Gasket Set

A complete overhaul gasket set is used during major rebuilds where the entire engine is disassembled. This kit includes every gasket and seal required to restore the 3412C to factory specifications, from top-end components to bottom-end assemblies.

Key Benefits:

-

Covers all major engine subsystems (intake, exhaust, fuel, oil, and cooling)

-

Reduces the risk of overlooked gaskets during rebuilds

-

Ideal for long-term fleet reliability and marine operators planning preventative maintenance

Cylinder Sealing Components

Cylinder Liner Seal Kit

Cylinder liners rely on sealing rings to prevent coolant leakage and maintain proper compression. Each liner requires its own seal kit, making this an essential component for in-frame and overhaul work.

Key Benefits:

-

One kit per liner ensures precise coolant sealing

-

Protects against liner cavitation and premature wear

-

Maintains combustion efficiency in the 3412C’s high-output design

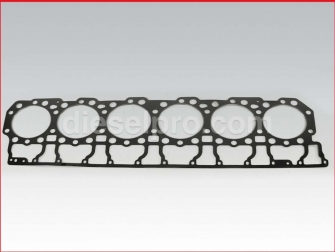

Head Gaskets

The Caterpillar 3412C uses two head gaskets per engine. These critical gaskets are engineered to handle extreme cylinder pressures and temperatures. Replacing them during overhauls ensures long-lasting performance and prevents combustion leaks.

Key Benefits:

-

Engineered for Caterpillar 3412C’s high compression and heavy-duty applications

-

Long service life with resistance to thermal stress

-

Recommended for both in-frame and major overhaul work

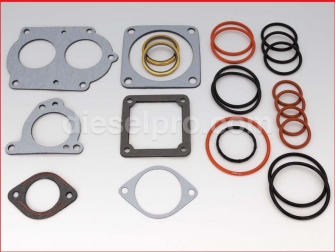

Auxiliary System Gasket Sets

Expansion Tank Gasket Set

The expansion tank manages coolant flow and prevents over-pressurization. Its gasket ensures a leak-free connection between the expansion tank and the cooling system.

Key Benefits:

-

Prevents coolant leakage at expansion tank joints

-

Essential for maintaining system pressure balance

-

Durable material for long-term sealing reliability

Aftercooler Gasket

The aftercooler gasket is a small but crucial component that maintains an airtight seal in the charge-air cooling system. This prevents unmetered air from entering the intake stream and ensures maximum turbocharger efficiency.

Key Benefits:

-

Enhances turbocharged air delivery efficiency

-

Prevents boost leaks and power loss

-

Designed for heat and pressure resistance

Air Compressor Gasket

The 3412C often drives auxiliary equipment like air compressors. The compressor gasket maintains the seal in these support systems, ensuring reliability for applications such as starting systems, pneumatic controls, or braking systems.

Key Benefits:

-

Maintains air system efficiency

-

Reduces risk of compressor oil leakage

-

Extends compressor service life

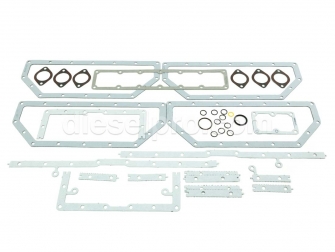

Exhaust Manifold Gasket

This gasket seals the joint between the exhaust manifold and the engine block. On a V12 engine like the 3412C, maintaining this seal is critical to preventing exhaust leaks, protecting turbochargers, and reducing heat damage to nearby components.

Key Benefits:

-

Prevents exhaust gas leakage

-

Protects surrounding components from heat exposure

-

Improves turbocharger efficiency and overall performance

Flywheel Housing Gaske

The flywheel housing gasket seals the connection between the flywheel housing and the block. A properly sealed housing protects against oil leakage and contamination, which is especially important in marine and industrial engines operating under constant load.

Key Benefits:

-

Ensures proper alignment and sealing of flywheel housing

-

Prevents oil leakage into transmission or bellhousing areas

-

Supports long-term drivetrain reliability

Turbocharger Gasket

Every turbocharger installation requires a gasket to prevent exhaust leaks. For the 3412C, this gasket is designed to withstand extreme exhaust temperatures and maintain performance.

Key Benefits:

-

Prevents exhaust leakage at turbo mounting flange

-

Maintains boost pressure integrity

-

Essential during turbocharger replacement or overhaul

Oil and Crankshaft Gaskets

Oil Pan Gasket

The oil pan gasket seals the oil sump against the engine block. Replacing this gasket during overhauls prevents oil leaks and ensures proper lubrication system performance.

Key Benefits:

-

Prevents oil seepage at the oil pan joint

-

Withstands vibration and thermal cycling

-

Critical for keeping engines clean and leak-free

Crankshaft Front Seal

Located at the front of the crankshaft, this seal prevents oil leakage near the timing gear train and accessory drives.

Key Benefits:

-

Protects against oil leaks at the front of the engine

-

Ensures reliability for high-speed crankshaft rotation

-

Helps maintain clean engine operation

Crankshaft Rear Seal

The rear crankshaft seal prevents oil leakage at the transmission interface, a common stress point in high-horsepower engines like the 3412C.

Key Benefits:

-

Prevents rear main seal leaks that could contaminate the flywheel or clutch area

-

Designed for heavy-duty industrial and marine applications

-

Long-lasting construction to minimize downtime

Why Choose Diesel Pro Power for Caterpillar 3412C Gasket Sets

Selecting the right gasket set for your Caterpillar 3412C engine is more than a matter of convenience—it’s about ensuring reliability, extending service life, and reducing costly downtime. Diesel Pro Power has become the preferred source for operators around the globe who rely on precision, speed, and expert support. Below are the reasons why thousands of customers consistently choose Diesel Pro Power for Caterpillar gasket sets and related components.

40,000+ Satisfied Customers Worldwide

With a customer base of more than 40,000 operators in over 180 countries, Diesel Pro Power has built a reputation for reliability. Our gasket sets are trusted by marine operators running high-output 3412C engines on vessels, by mining companies that depend on uninterrupted heavy-duty operation, and by industrial facilities where downtime equals lost revenue. Each order contributes to a long-standing tradition of excellence in supplying aftermarket Caterpillar parts with proven track records in demanding conditions.

Fast Global Shipping

When an engine as large and powerful as the 3412C requires attention, waiting weeks for parts is not an option. Diesel Pro Power ensures that all gasket sets and sealing components ship within 24 hours of purchase. Every shipment comes with real-time tracking, giving operators confidence and transparency from warehouse to delivery. Whether your 3412C powers a fishing vessel in Alaska, a generator in South America, or heavy machinery in the Middle East, fast and predictable shipping minimizes costly downtime.

Engine-Specific Catalogs

Unlike generic suppliers who list universal gaskets that may or may not fit your Caterpillar 3412C, Diesel Pro Power builds engine-specific catalogs. This means that every gasket set—whether it’s a complete overhaul kit, a head gasket set, or an oil pan gasket—is tailored exclusively to Caterpillar’s 3412C specifications. By eliminating guesswork, operators save time, avoid ordering errors, and ensure that every component fits perfectly the first time. This approach has made Diesel Pro Power the go-to choice for fleets, repair shops, and end users who demand accuracy.

Premium Quality Materials

The Caterpillar 3412C operates in environments where standard materials simply do not last. That is why Diesel Pro Power offers gaskets manufactured from premium materials engineered for high-temperature and high-pressure applications. From cylinder head gaskets that endure extreme combustion forces to oil seals that withstand constant thermal cycling, every gasket is tested to meet or exceed OEM performance. Customers benefit from reduced risk of premature failures, less frequent replacements, and confidence that their 3412C will continue operating at peak efficiency.

Expert Technical Support

Purchasing a gasket set is only one part of the process—knowing how to properly install and maintain it is equally important. Diesel Pro Power provides direct access to technical specialists with decades of Caterpillar engine experience. Whether you need guidance on torque sequences, sealing surface preparation, or compatibility between gasket types during in-frame versus complete rebuilds, our team offers step-by-step support. This expertise transforms a simple parts order into a complete maintenance solution.

The Diesel Pro Power Difference

When it comes to Caterpillar 3412C gasket sets, Diesel Pro Power delivers a combination of trust, speed, accuracy, quality, and technical support unmatched in the industry. That is why operators worldwide continue to rely on us as their one-stop solution for maintaining the performance and longevity of their engines.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588