Parts for Caterpillar 3412C for Australia - Oil Section

Loading...

Loading... Parts for Caterpillar 3412C – Oil System Section

The oil system is one of the most important elements of any Caterpillar 3412C engine. Built to deliver consistent lubrication, regulate engine temperature, and protect internal components from wear, the oil system must be kept in peak condition to ensure long life and reliable operation. At Diesel Pro Power, we stock a complete selection of oil system components for the Caterpillar 3412C, including oil pumps, oil cooler cores, installation kits, seals, gaskets, and filter service tools. With more than 40,000 satisfied customers worldwide, our goal is to keep your 3412C running strong with proven aftermarket parts, fast global delivery, and expert support.

Oil Pump for Caterpillar 3412C

The oil pump is the heart of the lubrication system in the 3412C. Its role is to pressurize and circulate oil throughout the crankshaft, bearings, piston cooling jets, camshaft, and valve train. A properly functioning oil pump ensures consistent pressure across all operating conditions, from cold start-up to peak load at full RPM.

Key Features of the 3412C Oil Pump

-

High-Volume Flow: Designed to deliver adequate lubrication to the 12-cylinder configuration of the 3412C.

-

Durable Construction: Precision-machined housing and gears provide long service life under high load conditions.

-

Engine Compatibility: Designed for use across multiple 3412 variants including 3412, 3412C, and 3412E engines.

-

Critical Protection: Prevents overheating and reduces friction, ensuring the long-term integrity of major engine components.

Regular inspection of the oil pump is crucial. Symptoms of a failing oil pump include low oil pressure warnings, increased engine noise, or accelerated bearing wear. Replacing the pump at the first sign of failure prevents costly engine damage.

Oil Cooler Core for Caterpillar 3412C

While the oil pump moves the lubricant, the oil cooler core regulates temperature. As oil flows through the cooler, excess heat is transferred to the coolant system, preventing breakdown of oil viscosity and maintaining optimal lubrication properties.

Why the Oil Cooler Core Matters

-

Temperature Control: Keeps oil within the safe operating range, even in heavy-duty or marine conditions.

-

Extended Oil Life: Prevents premature oil degradation caused by excessive heat.

-

Component Longevity: Reduces thermal stress on bearings, pistons, and cylinder liners.

Replacing a clogged or leaking cooler core ensures the lubrication system can continue to perform effectively under high stress.

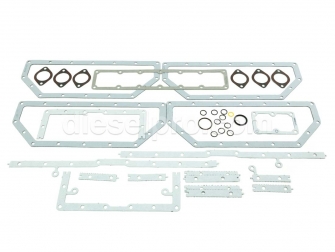

Oil Cooler Installation Kit

When servicing or replacing the oil cooler, an installation kit is essential to ensure a secure, leak-free fit. These kits include mounting hardware, seals, and gaskets to properly position the cooler and integrate it into the oil system.

-

Complete Assembly Support: Provides everything needed for correct installation.

-

Prevents Leaks: Ensures tight sealing and reliable operation.

-

Compatibility: Designed for use with Caterpillar 3412 oil cooler configurations.

Seal O-Rings for Oil Coolers

A small component that plays a big role, the oil cooler O-ring seals the interface between the cooler core and the engine block. A failing seal can cause external oil leaks or allow oil and coolant to mix—both scenarios that can cause major damage if left unchecked.

-

High-Temperature Tolerance: Built to withstand hot oil and coolant flow.

-

Precise Fit: Designed specifically for 3406, 3408, and 3412 engines.

-

Cost-Effective Maintenance: Regular replacement during servicing prevents larger failures.

Oil Pan Gasket for Caterpillar 3412C

The oil pan gasket seals the joint between the oil pan and the lower block. A strong seal is vital to prevent oil leaks and maintain crankcase pressure.

-

Durable Design: Resistant to oil saturation and heat cycling.

-

Leak Prevention: Ensures the oil reservoir remains sealed under vibration and load.

-

Service Recommendation: Replace any time the pan is removed during maintenance.

Oil Filter Removal Wrench

Maintaining the lubrication system means regularly changing the oil filter. A filter removal wrench makes this job quicker and prevents damage to the filter housing.

-

Adjustable Fit: Designed for oil filters used on Caterpillar, Detroit Diesel, and Cummins engines.

-

Ease of Use: Provides grip and leverage for stubborn or tight filter installations.

-

Essential Tool: Keeps service jobs efficient, preventing wasted time in the field or workshop.

Importance of a Healthy Oil System in the Caterpillar 3412C

The Caterpillar 3412C engine operates in some of the harshest environments—marine propulsion, power generation, oilfield operations, and heavy industrial applications. In each of these settings, the oil system plays a central role in performance and reliability.

-

Engine Protection: Proper oil flow prevents catastrophic bearing or piston failures.

-

Temperature Stability: Oil cooling protects against overheating during continuous load.

-

Extended Service Life: Clean, well-circulated oil maximizes the lifespan of major engine components.

-

Reduced Downtime: Replacing worn oil system parts prevents unscheduled breakdowns that cost fleets time and money.

Why Buy Caterpillar 3412C Oil System Parts from Diesel Pro Power

Trusted Worldwide – Diesel Pro Power has earned the confidence of more than 40,000 satisfied customers operating in over 180 countries. From commercial shipping fleets and offshore platforms to mining operations and industrial power plants, operators trust our oil system parts to keep their Caterpillar 3412C engines running reliably in the toughest conditions.

Premium Quality – Every oil pump, oil cooler core, seal, and gasket we supply is manufactured to meet or exceed Caterpillar performance standards. That means precision machining, durable materials, and reliable compatibility with 3412, 3412C, and 3412E engines. Choosing Diesel Pro Power ensures that your lubrication system maintains the correct oil pressure, reduces wear, and protects your investment over the long term.

Fast Global Shipping – We know that downtime is costly. Whether your Caterpillar engine powers a vessel at sea, a drilling rig in remote territory, or a generator supplying critical infrastructure, every hour of lost productivity matters. That’s why Diesel Pro Power provides expedited worldwide delivery, reducing waiting times and helping operators restore equipment quickly. No matter where your 3412C engine operates, you can rely on us to deliver the right part when you need it most.

Dedicated Catalog – Our Caterpillar 3412C catalog is carefully organized by system and component, making it simple to locate the exact part required. Instead of sorting through generic listings or navigating confusing databases, operators can go directly to oil system components such as pumps, cooler cores, gaskets, or seals. This streamlined catalog saves time and ensures accuracy when ordering critical engine parts.

Expert Technical Support – Selecting the correct oil pump design, identifying the proper cooler installation kit, or ensuring the right sealing components are used requires more than just a part number. Our experienced technical team is here to provide step-by-step guidance, helping operators make informed decisions and avoid costly mistakes. Whether you need advice on oil pump replacement intervals, gasket compatibility, or best practices for installation, Diesel Pro Power offers support tailored to your specific Caterpillar 3412C application.

By sourcing your Caterpillar 3412C oil system components from Diesel Pro Power, you gain more than just reliable parts—you gain a trusted partner dedicated to keeping your equipment productive, efficient, and protected for years to come.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588