Parts for Caterpillar 3412E for Australia - Cylinder Head Section

Loading...

Loading... Cylinder Heads & Related Components for Caterpillar 3412E Engines

The Caterpillar 3412E is a high-performance, twelve-cylinder diesel engine widely used in marine propulsion, offshore platforms, power generation, and heavy industrial machinery. Its robust design and electronically controlled fuel system deliver both reliability and efficiency in continuous-duty environments.

The cylinder head is central to the engine’s performance, housing the intake and exhaust valves, valve springs, seats, guides, and associated hardware. On the 3412E, precision in head assembly directly impacts compression, fuel combustion, and durability under demanding workloads.

Below you’ll find a detailed parts catalog for the Caterpillar 3412E cylinder head and related components, with explanations of function, maintenance considerations, and compatibility across the 3400 Series family.

Complete Cylinder Heads for Caterpillar 3412E

Fully Assembled Cylinder Head

The fully assembled cylinder head for the 3412E comes complete with valves and springs pre-installed. This option is ideal for operators seeking to minimize downtime during rebuilds, as the head arrives ready for installation with all core components set to OEM specifications. Using a new complete head ensures proper seating of valves, correct spring tension, and factory tolerances that extend engine service life.

Bare Cylinder Head

The bare version of the 3412E cylinder head is supplied without valves, springs, or related hardware. This option is preferred by rebuilders who want to customize valve materials or seating configurations, or who intend to reuse recently replaced components. The bare head offers a cost-effective foundation for a comprehensive rebuild project while maintaining OEM-level casting integrity.

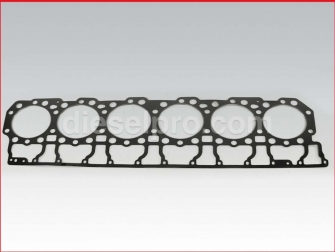

Cylinder Head Gaskets & Sealing Components

Cylinder Head Gasket Set

Each Caterpillar 3412E requires a comprehensive gasket set to ensure reliable sealing between cylinder head and engine block. The set typically includes upper deck gaskets, coolant seals, oil passages, and fire rings designed to handle extreme compression. For engines with serial prefixes such as 3JK, 7BL, 7HG, 9KS, and 9PW, selecting the correct gasket set is essential to prevent coolant or oil leaks under high thermal stress.

Individual Head Gaskets

In addition to full gasket sets, individual head gaskets are available for service scenarios where only one head requires attention. The Caterpillar 3412E uses two cylinder heads per engine, meaning two gaskets are needed for a complete top-end rebuild. High-temperature resistance and multi-layer construction help maintain proper compression in both marine and land-based applications.

Chamber Gaskets

Located around each fuel injector, chamber gaskets seal the combustion chamber from coolant and oil passages. The Caterpillar 3412E requires one chamber gasket per injector. Proper installation prevents blow-by gases and ensures efficient combustion, especially important in electronically controlled injection systems.

Cylinder Head Fasteners & Hardware

Head Bolts

Head bolts secure the cylinder head to the engine block, maintaining compression across the entire 12-cylinder configuration. Each bolt must withstand enormous tensile loads while also resisting stretching during heat cycles. For the 3412E, bolts are precision-machined with a fine-thread design to ensure even clamping force. Correct torque sequences during installation are essential for preventing head warping and gasket failure.

Head Bolt Washers

Washers distribute bolt load evenly across the cylinder head surface, reducing the risk of localized stress and potential cracking. They also provide a smooth interface that reduces friction when bolts are tightened, helping maintain accurate torque readings. Washers are critical on large displacement engines like the 3412E where clamping forces are extreme.

Valve Locks

Valve locks, also known as keepers, secure the valve spring retainer to the valve stem. The Caterpillar 3412E requires two locks per valve. Despite their small size, these components are essential to engine reliability—failure of a single lock can lead to dropped valves and catastrophic engine damage.

Valve Train Components

Intake Valves

The intake valves on the Caterpillar 3412E regulate airflow into the combustion chamber. A total of 24 intake valves are used across the twelve-cylinder configuration. Precision-machined valve faces and hardened stems provide durability against repeated seating under high pressure and temperature conditions.

Exhaust Valves

Exhaust valves manage the expulsion of combustion gases from the cylinders. Like the intake valves, there are 24 exhaust valves on a 3412E engine. Exhaust valves operate under extreme heat, requiring materials engineered for thermal resistance to prevent warping, pitting, or premature failure.

Valve Springs

Valve springs maintain valve seating and ensure proper timing by returning the valve to the closed position after each cycle. On the 3412E, springs must balance strength with flexibility, preventing valve float at high RPMs while avoiding excessive wear on camshaft lobes and valve stems.

Rotocoil Assemblies

Rotocoil assemblies sit beneath the valve spring and rotate the valve slightly during operation. This action promotes even wear on the valve face and seat, extending service intervals and improving combustion efficiency. The 3412E uses rotocoils on both intake and exhaust valves.

Valve Guides

Valve guides provide alignment for intake and exhaust valves, ensuring smooth movement as they open and close. They also conduct heat away from the valve stem into the cylinder head. Proper guide condition is crucial on the 3412E to prevent oil leakage into the combustion chamber and maintain compression integrity.

Valve Inserts (Seats)

Both intake and exhaust valves seat against hardened inserts pressed into the cylinder head. On the Caterpillar 3412E, valve seats resist high-pressure sealing forces while also withstanding corrosion from combustion gases. Regular inspection of inserts during rebuilds prevents valve recession and protects the cylinder head casting.

Supporting Components

Push Rods

Push rods transfer motion from the camshaft to the rocker arms, enabling valve actuation. On the 3412E, push rods must maintain rigidity to avoid bending under high stress. Worn or damaged push rods can cause valve timing issues, misfires, or uneven wear across the valve train.

Valve Lifters

Also known as tappets, lifters ride on the camshaft lobes and transmit motion to the push rods. Hydraulic or mechanical in design, lifters are subject to constant contact stress. In the Caterpillar 3412E, maintaining lifter condition ensures smooth camshaft operation and prevents premature wear of the valve train.

Maintenance Considerations for the Caterpillar 3412E Cylinder Head

-

Regular Valve Adjustment: Proper lash settings maintain efficiency and prevent overheating of valves.

-

Torque & Sequence Checks: Head bolts must be tightened to exact specifications to prevent gasket leaks.

-

Inspection of Valve Seats & Guides: Replacing worn components during top-end service prevents more costly damage later.

-

Coolant & Oil Management: Proper sealing of gaskets and chamber components prevents cross-contamination, a common cause of major repairs.

Why Choose Diesel Pro Power for Caterpillar 3412E Cylinder Head Parts

Global Reach: Diesel Pro Power ships worldwide with fast and reliable logistics, ensuring operators receive critical parts on time. With coverage in over 180 countries, vessel operators, power plant managers, and industrial facilities can minimize downtime by sourcing directly from a trusted supplier.

Proven Reliability: With a track record of more than 40,000 satisfied customers, Diesel Pro Power has become a trusted name in the marine and industrial diesel community. Our reputation is built on consistent quality, dependable inventory, and decades of experience supporting heavy-duty engines like the Caterpillar 3412E.

Complete Coverage: Our catalog goes beyond just cylinder heads. Customers can find every component required for a complete top-end service—head gaskets, bolts, washers, valves, springs, guides, and more—all organized by engine model for easy navigation. Whether you need a fully assembled head or individual hardware, everything is consolidated in one place.

Marine & Industrial Focus: Unlike general suppliers that cater primarily to automotive markets, Diesel Pro Power specializes in continuous-duty diesel engines. The Caterpillar 3412E is designed for demanding environments like marine propulsion, offshore drilling, and power generation, and our catalog reflects that focus by stocking only the components suited to those rigorous applications.

Expert Support: Selecting the correct components for a Caterpillar 3412E rebuild requires precision. Our experienced team helps customers verify compatibility based on engine model, serial prefix, or specific configuration. From identifying whether a full head assembly or bare casting is best suited, to confirming gasket set coverage for multiple head configurations, our specialists ensure accuracy and peace of mind.

Customer Commitment: Diesel Pro Power is more than a parts supplier—we are a long-term partner for fleet operators, repair shops, and industrial facilities. With knowledgeable staff, a comprehensive inventory, and streamlined global distribution, we help customers maintain the performance and reliability of their Caterpillar 3412E engines with confidence.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588