Cummins 4BTA Engine Parts for Australia - Fuel Pump Section

Loading...

Loading... -

-

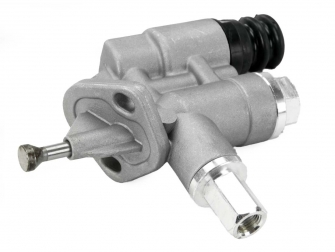

Cummins Fuel Transfer Pump

3936319

Pump Style Mechanical Piston, Used with non-rotary pumpsPrice: $ 101.38 -

-

-

-

-

-

Cummins Fuel Filter & Water Separator

3286503

3.02" diameter, 5.62" height, thread: M16 x 1.5" - 6H INTPrice: $ 44.78 -

-

-

-

1000 Racor Replacement fuel and water separator filter unit

1000

Filter element 2020 includedPrice: $ 449.65 -

-

-

-

-

-

-

Zinc for Cummins Marine Engine Fuel and Oil Coolers

3957921

Brass plug NPT 3/8”, zinc length 1”Price: $ 20.77 -

-

Fuel & Oil Pressure Switch - 10 PSI Make/Break

23520024

10 PSI make/break with 1/8 nptPrice: $ 99.79 -

Fuel & Oil Pressure Switch - 20 PSI Make/Break

23520025

20 PSI make, break with 1/8 nptPrice: $ 96.44 -

Fuel & Oil Pressure Switch - 27 PSI Make/Break

23511819

27 PSI make/break with 1/8 nptPrice: $ 81.10 -

Cummins 4BTA Engine Parts – Fuel Pump & Fuel System Components Catalog

The Cummins 4BTA 3.9-liter engine is widely recognized for its durability, fuel efficiency, and adaptability in both marine and industrial applications. One of the most critical systems that keeps this engine running reliably is its fuel delivery system. Whether powering a commercial fishing vessel, a generator set, or heavy industrial machinery, the fuel pump and related components ensure that the engine receives clean, pressurized fuel at the correct flow rate.

At Diesel Pro Power, we supply a complete range of fuel system components for Cummins 4BTA engines—including fuel transfer pumps, fuel injection pump gaskets, solenoids, fuel manifolds, filtration systems, and associated hardware. Our inventory supports not only the 4BTA but also the related Cummins 4B, 4BT, 6B, and 6BT platforms, ensuring compatibility and reliability across your fleet.

Fuel Transfer Pumps for Cummins 4BTA

The fuel transfer pump is the backbone of the Cummins 4BTA fuel system. It moves diesel from the fuel tank through primary filtration and delivers it to the injection pump. A failing transfer pump can cause hard starting, power loss, and erratic engine performance.

Mechanical Lever-Style Fuel Transfer Pump

Designed for Cummins 4BT and 6BT engines, the mechanical lever-style pump uses a camshaft-driven lever to create suction and move fuel. This simple and durable design is popular in marine applications because it doesn’t rely on electrical power—ensuring consistent fuel delivery even in challenging conditions.

Key features:

-

Rugged mechanical operation for reliability in remote or high-vibration environments.

-

Ideal for boats, industrial generators, and off-road machinery.

-

Easy service and replacement without specialized tools.

Mechanical Piston-Style Fuel Transfer Pump

Commonly used with non-rotary fuel injection pumps, this piston-style variant provides precise fuel delivery and excellent resistance to cavitation. It’s particularly well-suited for steady RPM industrial engines and continuous-duty marine propulsion systems.

Advantages:

-

Smooth, consistent fuel flow.

-

Longer service life under heavy load conditions.

-

Designed for stable fuel pressure to protect injectors and improve combustion efficiency.

Gaskets for Fuel Pumps and Injection Systems

Gaskets are small but critical components in preventing leaks and maintaining proper fuel pressure in a Cummins 4BTA fuel system.

Fuel Transfer Pump Gasket

A fuel transfer pump typically uses two gaskets—one on each side of the mounting flange—to ensure a complete seal between the pump and the engine block. Without a good seal, air can be drawn into the system, causing rough running or loss of prime.

Applications:

-

Used on Cummins 4BT, 6BT, 6CT, ISC, and QSC engines.

-

Designed to withstand diesel exposure and high vibration.

Fuel Injection Pump Gasket

This gasket seals the fuel injection pump to the engine mounting point, ensuring that no diesel leaks under high pressure. Given the precision required for injection timing, maintaining an airtight and leak-free seal is critical.

Fuel Shutoff Solenoids

The fuel shutoff solenoid allows for remote or automatic engine shutdown by cutting off the fuel supply. For the Cummins 4BTA, the 12-volt solenoid is a common choice in marine and industrial applications.

Functions:

-

Enables emergency shutdown in safety-critical situations.

-

Facilitates remote start/stop control.

-

Prevents engine run-on after shutdown.

Fuel Manifolds

The fuel manifold distributes fuel evenly from the transfer pump to the injectors or injection pump inlet. In the Cummins 4B and 4BT family, a properly functioning manifold ensures each cylinder receives an even supply of fuel for balanced combustion.

Fuel Filtration for Cummins 4BTA

Clean fuel is essential for extending injector life and preventing costly downtime. Diesel Pro Power offers both primary and secondary filtration solutions for the 4BTA platform.

Standard Spin-On Fuel Filters

These filters remove fine particulates before they reach the injection system.

-

Designed for optimal flow without sacrificing filtration efficiency.

-

Available in multiple micron ratings to match operational requirements.

Fuel Filter & Water Separator Units

Water contamination is one of the most common causes of injector and pump failure in diesel engines. The combination fuel filter and water separator removes both debris and moisture before the fuel reaches critical components.

Racor®-Style Fuel and Water Separator Systems

In marine environments, Racor fuel/water separators are the industry standard for protecting engines from water and debris contamination. Diesel Pro Power offers complete replacement units and filter elements compatible with Racor 500, 900, and 1000 series systems.

Complete Replacement Units

-

Racor 500 – Compact design, ideal for single-engine installations.

-

Racor 900 – Higher capacity for medium-duty marine and industrial engines.

-

Racor 1000 – Maximum filtration capacity for heavy-duty, long-range operations.

Replacement Filter Elements

Each Racor unit requires the correct element for effective filtration. Elements are color-coded by micron rating:

-

Brown Top – 2 Micron – Ultra-fine filtration for injector protection.

-

Red Top – 30 Micron – Coarse pre-filtration for high-contamination fuel sources.

Additional Fuel System Accessories

Marine Zinc Anodes for Fuel Coolers

In saltwater applications, zinc anodes protect fuel and oil coolers from galvanic corrosion. These sacrificial components are essential for extending the life of marine heat exchangers.

Fuel & Oil Pressure Switches

These switches monitor system pressure and can trigger alarms or shut down the engine in the event of low fuel or oil pressure. Available in multiple set points (5, 10, 20, and 27 PSI) to suit specific operational needs.

Fuel Filter Removal Wrenches

Specially designed tools for quick, safe removal of spin-on filters without damage.

Why Choose Diesel Pro Power for Your Cummins 4BTA Fuel System Parts?

With over 40,000+ satisfied customers worldwide, Diesel Pro Power has built a reputation for providing high-quality parts, fast shipping, and unmatched technical support. Every fuel system component we supply is backed by our commitment to reliability—whether you’re maintaining a workboat, servicing a standby generator, or keeping heavy equipment operational.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588