Cummins 6C Engine Parts for Australia - Engine Water Pump Section

Loading...

Loading... -

-

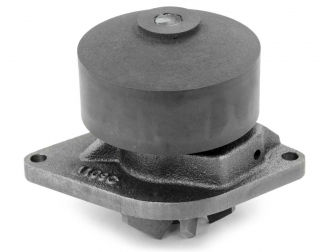

Engine Water Pump for Cummins 6C, 6CT, 6CTA Engines

3806180

For engines with CPL#s 604, 985, 1615, 1845, 1943, 1999, 2060, 2062, 2082, 2114, 2194, 2368

Price: $ 101.97 -

-

-

-

-

-

-

-

Belt for Cummins water pump, alternator and fan drive

3288689

Ribbed (8 ribs), serpentine V belt.

53.50” Long and 1.125” Wide

Price: $ 53.06 -

Cummins Multi-Groove Fan Belt

3288867

Ribbed (8 ribs), serpentine V belt

59” Long and 1.125” Wide

Price: $ 46.44 -

Belt for Cummins water pump, alternator and fan drive

3911562

Ribbed (8 ribs), serpentine V belt. 57.5" Long and 1.125" WidePrice: $ 44.25 -

Belt for Cummins water pump, alternator and fan drive

3911557

Ribbed (8 ribs), serpentine V belt.

59.50” Long and 1.125” Wide

Price: $ 48.64 -

Belt for Cummins water pump, alternator and fan drive

3911563

Ribbed (8 ribs), serpentine V belt.

60.0” Long and 1.125” Wide

Price: $ 52.70 -

Belt for Cummins water pump, alternator and fan drive

3289113

Ribbed (8 ribs), serpentine V belt

66.53” Long and 1.125” Wide

Price: $ 54.25 -

Cummins Serpentine Belt for Water Pump and Fan Drive

4931563

Ribbed (8 ribs), serpentine V belt. 60.50 Long and 1.125" WidePrice: $ 56.76 -

Belt for Cummins water pump, alternator and fan drive

3911567

Ribbed (8 ribs), serpentine V belt

66.92” Long and 1.125” Wide

Price: $ 58.74 -

Belt for Cummins water pump, alternator and fan drive

3289235

Ribbed (8 ribs), serpentine V belt

69.0” Long and 1.125” Wide

Price: $ 64.35 -

Hose Plain for Cummins 6C, 6CT & 6CTA engines

63241N

To connect the heat exchanger outletPrice: $ 69.90 -

Cummins Plain Hose for Coolant Filter

3897106

To Connect to Water Corrosion Resistor or coolant Filter.Price: $ 28.64 -

-

-

Temperature switch for Detroit Diesel, Cummins, Caterpillar engines

5146080

Closes at 205 degrees Fahrenheit.Thread size is 1/2 NPTPrice: $ 97.19 -

-

-

-

-

-

-

-

-

-

-

-

-

-

Clamp for a coolant and fuel Hose

10H

Effective Diameter Range:

Minimum 9/16", Maximum 1-1/16"

Price: $ 3.04 -

Clamp for a cooland and fuel Hose

5104592

Effective Diameter Range:

Minimum 1", Maximum 1.5"

Price: $ 4.52 -

Clamp for a coolant Hose

3412320

Effective Diameter Range:

Minimum 11/16", Maximum 1-1/4"

Price: $ 14.76 -

Clamp for a coolant Hose

4920417

Effective Diameter Range:

Minimum 13/16", Maximum 1-3/4"

Price: $ 15.78 -

Clamp for a coolant Hose

3922846

Effective Diameter Range:

Minimum 1-5/16", Maximum 2-1/4"

Price: $ 16.50 -

Clamp for a coolant Hose

3922847

Effective Diameter Range:

Minimum 1-9/16", Maximum 2-1/2"

Price: $ 16.68 -

Clamp for a coolant Hose

3922849

Effective Diameter Range:

Minimum 2-5/16", Maximum 3"

Price: $ 17.19 -

Clamp for a coolant Hose

5188036

Effective Diameter Range:

Minimum 2-7/8", Maximum 3.5"

Price: $ 5.16 -

Cummins 6C, 6CT & 6CTA Engine Water Pump and Cooling System Parts Catalog

The Cummins 6C series—spanning the 6C, 6CT, and 6CTA 8.3L diesel engines—has been a staple powerplant for industrial, marine, and heavy equipment applications for decades. Known for its torque-rich output and long service life, this engine platform demands a robust cooling system to sustain performance under continuous load and in variable climates.

This catalog highlights a full range of cooling system parts specifically tailored to the Cummins 6C engine family. Here, you’ll find freshwater pumps, thermostats, gasket and seal kits, belt-driven components, tensioners, coolant hoses, and mounting hardware, all engineered for maximum durability and compatibility.

Engine Water Pumps for Cummins 6C, 6CT, and 6CTA Engines

The water pump is the core component responsible for circulating coolant through the cylinder block, cylinder head, and heat exchanger or radiator. Without a properly functioning water pump, engines quickly overheat, risking head gasket failure, piston seizure, or long-term wear.

There are two primary water pump assemblies commonly used across the Cummins 6C platform, depending on configuration and CPL number.

Freshwater Pump for Cummins 6C Engines – CPL Specific

This water pump is specifically designed for several critical CPLs (Control Parts Lists), ensuring exact fitment and flow characteristics. It features robust construction and precision-cast impeller geometry for optimal circulation of coolant through high-load industrial and marine engines.

Fits the Following CPL Numbers:

-

604

-

985

-

1615

-

1845

-

1943

-

1999

-

2060

-

2062

-

2082

-

2114

-

2194

-

2368

Technical Features:

-

Cast iron housing for long-term durability in marine and high-heat environments

-

Precision-balanced impeller for vibration-free operation

-

Direct OE-style replacement with no modifications needed

-

Compatible with closed-loop and heat exchanger cooling systems

-

Engineered for fresh or treated water applications

This pump is ideal for operators running vessels, generator sets, or industrial equipment that require specific flow characteristics to maintain operating temperature within safe limits.

Freshwater Pump for Cummins 6C, 6CT, 6CTA, ISB 6.7, and QSB 6.7

This variant is a broader fitment pump compatible across several generations of the Cummins engine family, including later-model 6C, 6CT, and electronically controlled ISB/QSB engines. It is often used in configurations where standardization across fleet equipment is beneficial.

Application Range:

-

Cummins 6C, 6CT, 6CTA

-

ISB 6.7 and QSB 6.7 variants (mechanical and electronic)

-

Generator sets, marine vessels, and high-load industrial applications

Product Characteristics:

-

High-flow coolant movement for heavy-duty performance

-

Corrosion-resistant internal components for longevity in salt-laden air or industrial dust

-

Drop-in replacement for factory units

-

Matches both gear- and belt-driven accessory layouts

Whether your equipment features an earlier mechanical injection model or newer common-rail ISB/QSB systems, this pump offers a reliable replacement option.

Water Pump Seal and Thermostat Gasket

Anytime a water pump is removed or replaced, the corresponding water pump seal and thermostat gasket must also be installed new. Reusing old gaskets can lead to leaks and improper coolant circulation.

Water Pump Seal:

-

Provides leak-proof seal between pump and engine front housing

-

Resistant to coolant additives and thermal cycling

-

Should be replaced during every pump service

Thermostat Gasket:

-

Creates a reliable barrier between the thermostat housing and coolant outlet

-

Prevents seepage and ensures full pressure retention

-

Compatible with both vented and non-vented thermostats

Cummins 6C Series Thermostats

Thermostats regulate the opening and closing of the coolant passage based on engine temperature, allowing faster warm-ups and stable operating conditions.

Available Variants:

-

160°F Vented Thermostat:

Allows early opening for coolant circulation. Ideal for cooler ambient environments or marine use. Vented design promotes air release to prevent vapor lock. -

180°F Thermostat:

Preferred option for equipment that runs hot or under load for extended durations. Supports efficient combustion and consistent fuel economy. -

180°F Vented Thermostat:

Adds venting for quick air evacuation from the system. Great for high-altitude or marine environments where trapped air could cause temperature spikes.

Why Replace Thermostats Periodically?

-

Spring fatigue over time causes sluggish response

-

Sticking open leads to low engine temps, poor fuel economy

-

Sticking closed risks overheating and head damage

-

Vented options allow improved system priming during coolant fill

Belt Tensioners and Idler Pulleys

Belt Tensioners

The belt tensioner is responsible for maintaining proper pressure on the serpentine belt, which drives the water pump, alternator, and possibly other accessories. Two options are available:

-

Plain Pulley Style: Common on earlier mechanical engine versions. Works with smooth serpentine belts.

-

Grooved Pulley Style: Required for modern 8-ribbed belts. Offers improved tracking and reduced slippage under load.

Routine inspection of tensioners is crucial. Symptoms of a failing tensioner include:

-

Belt noise or squealing

-

Belt misalignment

-

Alternator or water pump under-speed

-

Vibration at idle

Idler Gear Pulley

This component serves as a fixed belt-routing support. It is grooved to match the ribbed belt design, ensuring optimal surface contact.

Serpentine Drive Belts

The Cummins 6C engine family relies on high-performance serpentine belts to drive its key accessories, including:

-

Engine water pump

-

Alternator

-

Mechanical or electric fan

-

Air conditioning compressor (in some configurations)

Common Specifications:

-

8-rib serpentine V-style

-

Width: 1.125 inches

-

Lengths: Range from 53.5” to 69.0”

-

Engineered for reduced stretch and maximum durability

Recommended Maintenance:

-

Inspect for cracks, fraying, or glazing every 250–500 hours

-

Replace anytime squealing or slippage is observed

-

Install with new tensioner and idler components for optimal longevity

Silicone Coolant Hoses

Silicone hoses are now the standard in marine and industrial engine cooling systems thanks to their durability and resistance to high temperatures, pressures, and chemical exposure.

Available Hose Sizes (Inside Diameter):

-

3/4”

-

1”

-

1-3/4”

-

1-7/8”

-

2”

-

2-1/8”

-

2-1/4”

-

2-3/8”

-

2-1/2”

-

2-3/4”

-

3”

-

3-1/2”

-

4”

Each hose is offered in 1-foot lengths for custom installations. Whether routing coolant from pump to heat exchanger or thermostat housing to reservoir, these hoses deliver secure and long-lasting service.

Heat Exchanger Outlet Hose

This molded or plain hose connects the outlet of the heat exchanger back to the engine. Used commonly in marine applications, it must withstand elevated pressures and high ambient engine room temperatures.

Installation Tip:

Check hose bend radius and clamping area for signs of wear or abrasion. Replace with exact-fit diameter and marine-rated clamp.

Hose Clamps for Coolant and Fuel Lines

Quality stainless steel clamps are vital to prevent leaks and maintain hose pressure integrity under thermal expansion. Clamps are available for both coolant and fuel systems and come in multiple diameter ranges to fit all hoses listed above.

Clamp Sizing Ranges:

-

9/16” to 1-1/16”

-

1” to 1.5”

-

11/16” to 1-1/4”

-

13/16” to 1-3/4”

-

1-5/16” to 2-1/4”

-

1-9/16” to 2-1/2”

-

2-5/16” to 3”

-

2-7/8” to 3.5”

Clamping Best Practices:

-

Replace every time a hose is changed

-

Apply uniform torque to avoid hose distortion

-

For marine use, ensure clamps are 316 stainless steel or equivalent

Radiator & Heat Exchanger Cleaner

For engines operating in sediment-heavy water or with aging coolant systems, radiator flushing with a quality cleaner restores heat exchanger efficiency. It breaks down scale, rust, and chemical buildup from coolant pathways.

Use Cases:

-

After coolant contamination

-

During full system overhaul

-

Seasonal marine maintenance

Temperature Switches

Temperature switches act as safety mechanisms in case of cooling system malfunction. Often installed in the cylinder head or coolant outlet, these switches automatically activate a shutdown system, alarm, or cooling fan when a certain temperature threshold is reached.

Most Common Settings:

-

Activates at 205°F

-

Thread: 1/2" NPT

-

Compatible with Detroit Diesel, Cummins, and Caterpillar

This switch is a critical backup device and should be tested annually.

Engine Monitoring Gauges

Real-time temperature monitoring is essential in all diesel engine applications. Gauges are available in mechanical and electric styles, suitable for 12V and 24V systems.

Available Types:

-

Standard mechanical temp gauge

-

Mechanical gauge with integrated overheat alarm

-

Electric 12V gauge for trucks, buses, and gensets

-

Electric 24V gauge for marine and industrial installations

Installation Tip:

Match gauge sender and display unit voltage to prevent inaccurate readings.

Cooling System Troubleshooting & Maintenance Schedule

|

Issue |

Likely Cause |

|

Overheating at idle |

Failing water pump, clogged heat exchanger |

|

Rapid temperature rise under load |

Thermostat stuck closed, low coolant level |

|

Coolant loss |

Leaking hose, failed gasket, worn clamp |

|

Belt squeal |

Loose or glazed belt, worn tensioner |

|

Coolant discoloration |

Old coolant, scale buildup |

Recommended Service Intervals:

|

Component |

Inspection Interval |

Replacement Interval |

|

Water pump |

500 hours |

1500–2000 hours |

|

Thermostat |

250–500 hours |

12–24 months |

|

Serpentine belts |

250 hours |

Annually or 1000 hours |

|

Tensioner and idler |

500 hours |

As needed |

|

Silicone hoses |

250 hours |

Every 2–3 years |

|

Hose clamps |

With every hose |

With every hose |

|

Radiator cleaner |

N/A |

Every 12 months |

|

Temp switch |

500 hours |

Every 24 months |

Why Diesel Pro Power?

With over 40,000 satisfied customers globally, Diesel Pro Power is a leading supplier of genuine and aftermarket Cummins parts for marine and industrial engines. Our curated catalog ensures direct fitment, marine-grade reliability, and fast international shipping.

We Offer:

-

CPL-specific pump compatibility

-

Marine-rated hoses and clamps

-

One-stop shop for 6C cooling systems

-

Dedicated support for part selection

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588