Cummins 6B Engine Parts for Australia - Oil Pump Section

Loading...

Loading... -

Cummins Oil Pump

4939587

For engines with a front gear train.

Pinions have 23/24 Helix Teeth.For engines with CPL#s 591, 599, 714, 721, 742, 831, 1279, 1288 ,1519, 1522, 1523, 1524, 1551, 1816, 1889, 1914, 1948, 1961, 1962, 1975, 2014, 2063, 2071, 2122, 2205, 2208, 2242, 2243, 2292, 2347, 2372, 2373, 2446, 2447, 2486, 2530, 2686, 2891, 2893, 8208, 8217, 8236, 8266, 8267, 8304, 8305, 8306, 8444

Price: $ 104.45 -

Cummins Oil Pump

4897481

For engines with a front gear train.

Pinions have 22/24 Straight Teeth.For engines with CPL#s 0742, 8206

Price: $ 104.45 -

-

-

-

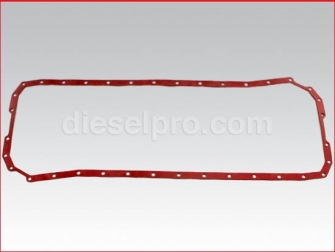

Cummins Oil Pan Gasket for 6B, 6BT & 6BTA Engines

4337597

Segmented Gasket. Included Oil pick up tube gasket.Price: $ 78.63 -

Oil Pan Bolts for Cummins 6B, 6BT & 6BTA

3900631

36 per engine - Oil Pan Bolts for Cummins 6B, 6BT & 6BTA; OEM-quality fasteners.Price: $ 5.78 -

-

-

-

Cummins Oil Filter

3908616

Spin-on type. 3.66" outside diameter, 5.35" height, thread size: 1-16 UNPrice: $ 25.74 -

Cummins Oil Filter

3937743

Spin-on type, 3.66" outside diameter, 6.95" height, thread size: 1-16 UNPrice: $ 32.80 -

Oil Filter Removal Wrench for Detroit Diesel, Caterpillar & Cummins

2321

4-21/32" to 5-5/32"Price: $ 63.29 -

Zinc for Cummins Marine Engine Fuel and Oil Coolers

3957921

Brass plug NPT 3/8”, zinc length 1”Price: $ 20.77 -

-

Fuel & Oil Pressure Switch - 10 PSI Make/Break

23520024

10 PSI make/break with 1/8 nptPrice: $ 99.79 -

Fuel & Oil Pressure Switch - 20 PSI Make/Break

23520025

20 PSI make, break with 1/8 nptPrice: $ 96.44 -

Fuel & Oil Pressure Switch - 27 PSI Make/Break

23511819

27 PSI make/break with 1/8 nptPrice: $ 81.10 -

Oil Pump & Lubrication System Components for Cummins 6B Engines

A reliable oil pump is the heart of the Cummins 6B lubrication system, ensuring continuous oil circulation to reduce friction, cool critical components, and extend engine life. Whether you are running a Cummins 6B, 6BT, ISB 6.7, or QSB 6.7 in a marine vessel or an industrial application, maintaining a healthy oil pump and its related components is essential for peak performance.

This section covers high-quality replacement oil pumps, oil coolers, gaskets, filters, and pressure switches, all built to OEM specifications. Diesel Pro Power has supplied these parts to over 40,000 satisfied customers, making us a trusted source for marine and industrial Cummins maintenance worldwide.

Cummins 6B Oil Pump – Front Gear Train Applications

The Cummins 6B engine family uses a gear-driven oil pump mounted in the front gear housing to ensure dependable oil flow under all load conditions. Two primary gear configurations are used:

-

23/24 Helix Teeth Design – Common in engines with specific CPL configurations, this version provides smoother gear engagement and reduced noise.

-

22/24 Straight Teeth Design – A robust and simpler gear profile used in select CPL groupings, known for durability in heavy-duty environments.

Both designs are engineered for precise oil metering, maintaining optimal pressure even under high-load and high-RPM operation. Marine users benefit from the pump’s ability to handle prolonged idle periods without oil starvation, while industrial operators appreciate its resilience under continuous duty cycles.

Oil Coolers for Cummins 6B Engines

The oil cooler is the unsung hero of your lubrication system, dissipating excess heat from the engine oil to prevent breakdown and viscosity loss. Cummins 6B engines typically use stacked plate oil coolers, with variations based on the number of plates for different cooling capacities:

-

5-Plate Oil Cooler – Compact and efficient, ideal for standard-duty applications.

-

7-Plate Oil Cooler – Increased surface area for higher cooling demand, recommended for heavy-duty, high-load, or hot-climate operation.

Both versions are constructed from corrosion-resistant materials suitable for marine and industrial environments. When paired with proper maintenance and clean oil flow, these coolers can dramatically extend bearing and piston life.

Oil Pan Gaskets for Cummins 6B

A quality oil pan gasket ensures a tight seal between the oil pan and engine block, preventing leaks that can cause gradual oil loss. Our Cummins 6B oil pan gaskets are made from premium sealing compounds that withstand both the constant vibration of marine engines and the thermal expansion cycles of industrial equipment.

Oil Cooler Core Gaskets

These gaskets seal the mating surfaces between the oil cooler core and the housing, ensuring no oil leaks into the cooling system or outside the engine. A failed gasket in this area can cause both oil pressure loss and coolant contamination—issues that can lead to major engine damage if ignored.

Oil Filter Head Gaskets

Oil filter head gaskets seal the filter housing to the engine block, ensuring oil flows directly through the filter without bypassing. A worn or damaged gasket can lead to unfiltered oil reaching bearings, turbochargers, and other sensitive components.

Oil Filters for Cummins 6B

Oil filters are critical for trapping soot, carbon, and microscopic metal particles that naturally accumulate in the lubrication system. Our Cummins-approved spin-on filters are available in multiple heights and capacities to suit your maintenance schedule and operating conditions:

-

Standard Height Filters – Balance between filtration surface area and compact fitment.

-

Extended Height Filters – Increased capacity for long service intervals, ideal for high-hour marine engines.

Oil Filter Removal Tools

An oil filter wrench designed for Cummins engines ensures quick and damage-free filter changes. This is especially valuable in confined engine rooms where access is limited.

Zinc Anodes for Marine Oil & Fuel Coolers

For marine Cummins 6B engines, zinc anodes protect oil and fuel coolers from galvanic corrosion caused by seawater exposure. Regular anode replacement is one of the most cost-effective ways to prevent expensive cooler failures.

Fuel & Oil Pressure Switches

Pressure switches monitor vital lubrication system parameters and trigger alarms if oil pressure falls below safe operating limits. We carry versions with different make/break pressures, including 5 PSI, 10 PSI, 20 PSI, and 27 PSI, to match various control system requirements.

Gauges for Monitoring Oil Pressure

Keeping an eye on oil pressure is essential for engine longevity. Options include:

-

Mechanical Gauges – Direct pressure reading for accurate real-time monitoring.

-

Electrical Gauges (12V or 24V) – Easy integration with helm or control panels.

-

Gauges with Alarm Function – Provide both a visual reading and an audible warning for added safety.

Maintenance Tips for the Cummins 6B Lubrication System

-

Change Oil Regularly – Follow Cummins’ recommended intervals, adjusting for heavy use or harsh conditions.

-

Inspect the Oil Pump Drive Gears – Wear or damage can reduce oil flow and pressure.

-

Replace Gaskets During Service – Avoid reusing old gaskets to ensure leak-free operation.

-

Flush the Oil Cooler When Overhauling – Prevents contaminants from circulating after repairs.

-

Monitor Oil Pressure Closely – Any sudden drop should be investigated immediately.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588