Cummins ISB 6.7 Parts for Australia - Gasket Section

Loading...

Loading... -

-

-

-

-

-

-

-

-

-

-

-

762 Hi-Temperature jointing compound for Detroit Diesel and Cummins turbos

762

225 gm tube - Temp range 550C to 760CPrice: $ 188.19 -

-

-

-

-

Gasket Spray -High Tack Sealant (Hold & Seals Cut Gaskets)

99MA

For Detroit Diesel & Cummins engines. Available for ground shipping only in USA and CanadaPrice: $ 25.67 -

3H Gasket Maker

3H

For Detroit Diesel & Cummins engines. Available for ground shipping only in USA and CanadaPrice: $ 17.46 -

-

-

-

-

Gasket Maker - Ultra Blue RTV Silicone Sensor Safe

77BR

For Detroit Diesel & Cummins enginesPrice: $ 11.03 -

Cummins ISB 6.7 Gaskets & Sealing Components

Introduction to Cummins ISB 6.7 Gaskets

The Cummins ISB 6.7 engine, widely used in marine, industrial, and on-highway applications, depends on a variety of gaskets and seals to maintain performance and reliability. Gaskets perform a critical role—providing a leak-proof seal between components, preventing the escape of fluids, gases, or combustion pressure, and ensuring optimal operating efficiency.

For the ISB 6.7 platform, the quality of gaskets and their correct installation can mean the difference between years of dependable service and costly downtime. From full upper and lower gasket sets to specialized seals for oil pans, water pumps, turbochargers, and intake systems, each component plays a unique role in protecting your engine from internal and external leaks.

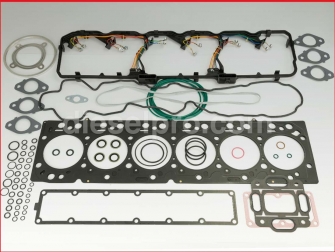

Complete Gasket Kits for Cummins ISB 6.7

Upper Gasket Set for Cummins ISB 6.7

An upper gasket set includes all the critical gaskets and seals located in the upper half of the engine. This typically covers the cylinder head gasket, intake and exhaust manifold gaskets, valve cover gasket, injector seals, and related O-rings. These components are designed to withstand high combustion pressures and thermal cycling.

Key benefits of a high-quality upper gasket set include:

-

Restored compression and sealing performance.

-

Prevention of coolant and oil cross-contamination.

-

Long-term resistance to thermal stress and warping.

Upper gasket sets are essential during a cylinder head rebuild or top-end overhaul. In marine environments where salt exposure is common, replacing aged gaskets helps maintain both power output and fuel efficiency.

Lower Gasket Set for Cummins ISB 6.7 (Rear Gear Train Models)

The lower gasket set is designed for the bottom end of the engine, sealing areas such as the oil pan, crankshaft seals, water pump gaskets, and rear main seals. For ISB 6.7 engines with a rear gear train configuration, these gaskets are specifically matched to ensure proper fitment and sealing.

Benefits of replacing the lower gasket set include:

-

Reduced oil seepage and loss of lubrication.

-

Protection against contaminants entering the crankcase.

-

Prevention of gear housing leaks, which can compromise timing and lubrication.

Individual Cummins ISB 6.7 Gaskets

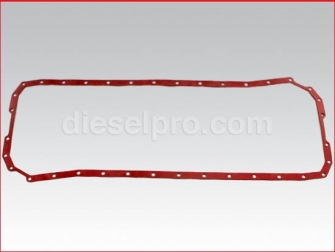

Oil Pan Gasket

The oil pan gasket forms a leak-proof seal between the oil pan and the engine block, ensuring that the engine retains proper lubrication levels. On the ISB 6.7, this gasket must resist both vibration and thermal expansion.

Marine applications demand extra attention here, as a compromised oil pan gasket can lead to dangerous oil loss during operation. Periodic inspections are recommended—look for signs of seepage around the oil pan rails.

Gasket for Oil Pick-Up Tube

The oil pick-up tube gasket ensures a tight seal where the pick-up tube mounts to the oil pump. A failed seal here can cause air intrusion into the lubrication system, leading to reduced oil pressure and potential bearing damage. Replacing this gasket during any oil pump service is standard preventive maintenance.

Intake Manifold Cover Gasket

This gasket seals the intake manifold cover to the cylinder head, preventing air leaks that could disrupt air-fuel ratios. Any breach in this seal can lead to poor engine performance, rough idling, or reduced turbo efficiency.

High-quality gaskets in this location are built to withstand elevated intake air temperatures and the constant pressure fluctuations of turbocharged operation.

O-Ring for Aftercooler

The aftercooler (charge-air cooler) O-ring seals the connection between the cooler housing and the adjoining pipework. On the ISB 6.7, a leaking O-ring can allow boost pressure to escape, reducing power and increasing exhaust gas temperatures. Marine users should also watch for salt corrosion around aftercooler housings, which can shorten seal life.

Valve Cover Gasket

The valve cover gasket prevents oil from escaping the top of the engine where the rocker arms and injectors are located. Over time, heat and oil exposure can cause this gasket to harden and shrink. Replacement helps maintain a clean engine bay and reduces the risk of oil dripping onto exhaust components.

Fuel Transfer Pump Gasket

This small yet essential gasket seals the interface between the fuel transfer pump and the engine. Without a proper seal, fuel leaks can occur, posing both efficiency and safety hazards.

Fuel Injection Pump Gasket

This gasket seals the fuel injection pump to the timing gear housing or adapter plate. A compromised gasket here can allow fuel to leak externally or air to enter the injection system, both of which can severely impact performance.

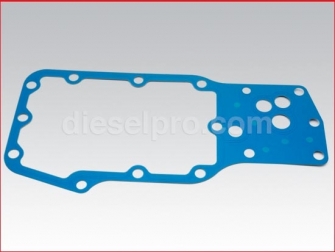

Gasket for Oil Cooler Cover

The oil cooler cover gasket prevents coolant and oil from mixing within the cooler assembly. The ISB 6.7 uses an oil cooler to regulate lubricant temperature under heavy load, making a strong seal here vital to engine health.

Turbo Oil Drain Gasket

Located at the turbocharger oil drain connection, this gasket ensures that returning oil from the turbo flows cleanly back into the crankcase without leakage. Turbo drain gaskets must handle both high temperatures and continuous oil flow.

Specialized Sealants & Jointing Compounds

Hi-Temperature Jointing Compound for Turbos

Designed to withstand extreme heat (up to 760°C), this compound seals turbocharger flanges and prevents exhaust gas leaks under high boost pressures.

Oil Cooler Core Gasket

The oil cooler core gasket seals the core element to its housing, ensuring efficient heat exchange between oil and coolant. Any failure here risks cross-contamination or reduced cooling efficiency.

Water Pump Seal Ring

A small but critical component, the water pump seal ring prevents coolant from escaping at the pump’s mounting interface.

Thermostat Seal

The thermostat seal ensures coolant flows only through the intended passages, preventing bypass leakage that could disrupt engine temperature regulation.

Sealants, Adhesives & Gasket Makers for Cummins ISB 6.7

The ISB 6.7 gasket system also relies on specialized chemical sealants to augment mechanical seals:

-

Gasket Spray – High Tack Sealant: Holds paper or fiber gaskets in place during assembly.

-

3H Gasket Maker: Liquid sealant for custom sealing applications.

-

High Strength Threadlocker (Red): Prevents critical fasteners from loosening under vibration.

-

Silicone Gasket Makers: Available in sensor-safe and high-temperature formulations.

-

Cold Weld Epoxy: For emergency repairs on metal surfaces.

-

Non-Hardening Pliable Sealant: Remains flexible for applications that require re-service.

Installation & Maintenance Best Practices

Preparation Before Gasket Replacement

-

Clean all mating surfaces to remove old gasket material and residue.

-

Inspect for warping or scoring on the sealing surfaces.

-

Check torque specs and follow Cummins tightening sequences.

Common Signs a Gasket Needs Replacement

-

Oil or coolant seepage around joints.

-

Loss of boost pressure.

-

Unusual temperature fluctuations.

-

Increased oil consumption or fuel odor.

Preventing Premature Gasket Failure

-

Use OEM-spec gaskets designed for the ISB 6.7.

-

Avoid over-tightening bolts.

-

Maintain proper coolant and oil levels to reduce thermal stress.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588