Cummins ISX Dual Cam Parts for Australia - Rebuild Kit Section

Loading...

Loading... Cummins ISX Dual Cam Parts – Rebuild Kit Section

The Cummins ISX Dual Cam engine is one of the most powerful and sophisticated heavy-duty diesel engines ever produced by Cummins. Its dual overhead camshaft (DOHC) design allows independent operation of the intake and exhaust valves, resulting in improved airflow, better combustion, and increased efficiency. Designed for performance and reliability in demanding industrial, on-highway, and marine applications, this engine represents a major advancement in Cummins engineering.

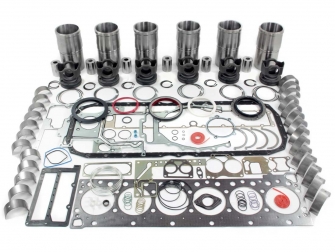

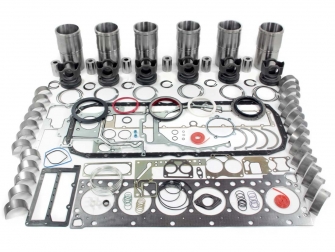

The Cummins ISX Dual Cam Rebuild Kit section at Diesel Pro Power is designed to give you everything needed to restore your ISX engine’s power, reliability, and performance. Whether you are performing a full in-frame overhaul or preparing for a top-end refresh, these kits offer OEM-grade quality components, engineered for precise fitment across multiple CPL configurations.

Complete ISX Dual Cam Rebuild Kits

Rebuilding a Cummins ISX engine is a major investment, and choosing the correct kit is essential to ensure compatibility and long-term reliability. Diesel Pro Power offers multiple ISX rebuild kit configurations, each tailored to specific CPL (Control Parts List) numbers. The CPL number ensures that every piston, liner, gasket, bearing, and seal matches your engine’s original factory specifications.

Cummins Rebuild Kit for ISX – 1 Piece Piston

This rebuild kit is designed for engines equipped with one-piece pistons and covers CPL numbers including 1771, 2440, 2441, 2627, 2628, 2629, 2631, 2632, 2803, 2814, 2933, 2934, 8046, 8047, 8083, 8048, 8242, 8243, 8244, 8255, 8257, and 8258.

These CPL numbers correspond to some of the most widely used ISX Dual Cam configurations in over-the-road trucks, power generation systems, and marine applications. The rebuild kit includes all essential internal components such as pistons, piston rings, cylinder liners, connecting rod bearings, main bearings, and a complete gasket set.

Each piston in this kit is manufactured to Cummins' precise compression ratio and metallurgy standards, ensuring proper cylinder pressure, oil control, and long service life. The one-piece piston design simplifies assembly and provides excellent resistance to cracking under high combustion temperatures.

Cummins Rebuild Kit ISX – 1 Piece Piston (Alternate CPL Sets)

The second configuration supports CPLs such as 927, 1434, 2733, 2734, 2919, 2965, 3167, 3320, 3458, 8125, 8281, 8283, 8284, 8285, 8286, 8518, 8519, 8521, 8522, and 8660.

These engines are often found in high-mileage Class 8 trucks and heavy-duty construction equipment. This kit is optimized for consistent compression across all cylinders and includes all necessary components for a full in-frame rebuild. Bearings are pre-sized for the correct oil clearances, ensuring optimal lubrication throughout the engine’s life.

This particular rebuild kit is popular among fleet operators seeking long-term value. The components are engineered for durability, allowing the engine to perform efficiently under sustained high loads. Diesel Pro Power’s rebuild kits are tested to meet or exceed Cummins factory standards for pressure, temperature, and tolerance.

Cummins Rebuild Kit ISX – 1 Piece Piston (High-Output CPLs)

The third ISX rebuild kit covers CPLs 1437, 2732, 3229, 3459, 3775, 8287, 8288, 8520, 8523. These CPLs are associated with higher-horsepower ISX models designed for applications where torque and load demands are extreme.

This version of the rebuild kit includes heavy-duty pistons designed to handle elevated cylinder pressures. The ring pack is engineered for improved sealing under high compression, contributing to better fuel efficiency and reduced oil consumption. Cylinder liners feature precision crosshatch patterns to promote efficient lubrication during break-in and throughout the engine’s life.

Each kit also includes reinforced head and main gaskets, ensuring leak-free operation under high boost and thermal stress.

Cummins Rebuild Kit for ISX – 1 Piece Piston (Extended CPL Compatibility)

The fourth rebuild kit option supports CPLs 2442, 2483, 2630, 2633, 2801, 2816, 2834, 2835, 2836, 2837, 2900, 8246, and 8247.

These engines are common in both long-haul and industrial stationary applications. This rebuild kit emphasizes balance between power and longevity, using pistons and liners with consistent compression ratios for smooth engine performance. The kit components are engineered to handle both variable-load and continuous-duty operations.

Each rebuild kit includes premium bearings, fully machined liners, and all major seals and gaskets. The included piston rings are precision cut for consistent cylinder sealing, which improves compression and extends engine life.

Supporting Components and Tools for ISX Rebuilds

A full rebuild of a Cummins ISX Dual Cam engine requires more than pistons and liners. Diesel Pro Power carries a complete selection of supporting components and professional-grade tools that make the overhaul process smoother and ensure proper reassembly.

Each ISX and QSX engine uses piston cooling nozzles to spray oil directly onto the underside of the pistons, maintaining ideal operating temperatures. Six nozzles are required per engine. These components are critical for preventing piston crown damage and maintaining proper lubrication under high-heat, high-pressure conditions. Replacing worn or clogged nozzles during an overhaul is highly recommended to prevent uneven piston cooling.

Crankshaft Seal Kits – Front and Rear

Proper crankshaft sealing ensures your engine maintains oil pressure and prevents leaks. Diesel Pro Power offers front and rear crankshaft seal kits for the ISX engine.

-

Front Seal Kit: Includes both the seal and sleeve, ensuring a proper fit on the front timing cover.

-

Rear Seal Kit: Also includes the seal and sleeve, designed to fit tightly around the crankshaft’s rear journal.

Replacing these seals during every rebuild helps maintain crankcase pressure balance and prevents contamination of the clutch or flywheel housing.

Filtration Components

High-efficiency filtration is essential for extending the life of your rebuilt Cummins ISX Dual Cam engine. Diesel Pro Power provides OEM-quality oil and fuel filters that meet Cummins specifications.

-

Cummins Oil Filter: Features a 4.65" diameter and 11.69" height with a thread size of 2 ¼" – 12 UN. This large-capacity spin-on filter ensures optimal oil flow and trapping efficiency, protecting vital engine components from abrasive particles.

-

Cummins Fuel Filter: Designed with a 3.68" diameter and 6.92" height, using a 7/8" – 14 UNF-28 thread. This filter effectively removes contaminants before they reach the injectors.

-

Fuel Filter & Water Separator: Equipped with a 1"-14 UN thread, this component helps separate water from the fuel, protecting high-precision injectors from corrosion and poor combustion.

Regular replacement of these filters is essential, especially during the break-in period following a full rebuild.

Specialty Tools

Diesel Pro Power also supplies specialized tools for rebuilding ISX engines efficiently and safely.

-

Piston Ring Assembly Tool: Designed for both Cummins and Detroit Diesel engines, this tool simplifies installation of piston rings without causing deformation or scoring.

-

Fuel Filter Removal Wrench: Adjustable between 3-7/16" and 3-3/4", compatible with both Detroit and Cummins filters.

-

Oil Filter Removal Wrench: Designed for filters ranging from 4-21/32" to 5-5/32", ensuring a secure grip and easy removal during maintenance.

-

Feeler Gauge: Precision-calibrated from .002" to .025", this tool allows accurate valve lash adjustment—a crucial step when reinstalling the cylinder head on ISX Dual Cam engines.

Proper use of these tools not only speeds up assembly but also ensures professional-level accuracy and safety during your rebuild project.

Cooling System Maintenance

Maintaining proper cooling efficiency is essential after an overhaul. Diesel Pro Power offers components like the radiator cleaner, which helps remove scale and deposits that restrict coolant flow. Available for ground shipping within the USA and Canada, this cleaner ensures that your rebuilt engine runs at ideal temperatures and that coolant channels remain free of corrosion or buildup.

The temperature switch used in Cummins ISX engines helps regulate cooling fan engagement and safeguards against overheating. This component closes at approximately 205°F and features a ½" NPT thread for straightforward installation. Replacing this switch during a rebuild is a simple but essential preventive step to maintain temperature control under heavy load conditions.

Gauges and Monitoring

No rebuild is complete without ensuring proper monitoring systems. Diesel Pro Power carries mechanical and electrical gauges compatible with Cummins ISX engines:

-

Mechanical Standard Gauges – Reliable and simple, ideal for direct engine installations.

-

Mechanical Gauges with Alarm – Include visual and audible warnings for temperature or pressure deviations.

-

Electrical Gauges (12V and 24V) – Suitable for electronically controlled ISX engines, allowing real-time monitoring of oil pressure, coolant temperature, and voltage.

Installing accurate gauges helps protect your rebuilt engine from potential failures caused by overheating, oil starvation, or electrical irregularities.

Why Choose Diesel Pro Power for Cummins ISX Dual Cam Rebuild Kits

With over 40,000 satisfied customers worldwide, Diesel Pro Power is the trusted source for genuine, high-quality diesel engine parts. Every ISX rebuild kit and accessory is backed by expert support and fast, reliable shipping.

Diesel Pro Power’s inventory includes not only complete in-frame rebuild kits but also individual parts like bearings, seals, filters, and sensors—everything required to bring your Cummins ISX engine back to peak condition.

Key advantages include:

-

Engine-Specific Kit Design: Each rebuild kit is tailored to match exact CPL configurations for proper fitment and performance.

-

High-Quality Components: Only OEM-grade materials are used, ensuring strength, precision, and longevity.

-

Comprehensive Coverage: Kits include all critical components needed for a full rebuild—pistons, rings, liners, gaskets, seals, and bearings.

-

Dedicated Customer Support: Diesel Pro Power provides detailed technical guidance to ensure correct CPL identification and installation.

Best Practices for Rebuilding a Cummins ISX Dual Cam Engine

A successful overhaul requires meticulous preparation and correct assembly procedures. Below are key recommendations to follow:

1. Identify Your CPL Number

Always match your CPL number to the correct rebuild kit before disassembly. The CPL ensures every part corresponds exactly to your engine’s specifications.

2. Inspect Components Before Installation

Check liners, pistons, and bearings for shipping damage or manufacturing defects before installation. Clean all components thoroughly to remove any protective coatings or debris.

3. Measure Clearances Carefully

Use feeler gauges and micrometers to verify crankshaft and camshaft bearing clearances. Cummins engines are precision-built, and maintaining exact tolerances is critical for longevity.

4. Replace Cooling and Lubrication Components

Never reuse old oil coolers, filters, or seals during a rebuild. These components are inexpensive compared to the cost of another teardown.

5. Use Assembly Lubricant

Proper lubrication during assembly reduces initial wear during the first few engine revolutions after startup.

6. Monitor During Break-In

After reinstallation, keep close watch on oil pressure, coolant temperature, and exhaust smoke during the break-in period. Diesel Pro Power recommends following Cummins’ official break-in procedure for optimal piston ring seating and fuel economy.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588