Cummins KTA 38 Engine Parts for Australia - Cylinder Head Section

Loading...

Loading... Cummins KTA38 Cylinder Head Parts Catalog

The Cummins KTA38 is a high-performance, V12 industrial diesel engine commonly used in marine vessels, mining equipment, oil and gas applications, and large-scale power generation systems. Renowned for its reliability, the KTA38 features twelve individual cylinders, each with its own cylinder head. This design allows for flexible servicing and superior heat dissipation, but it also means a full top-end rebuild involves replacing or servicing 12 separate heads and 12 head gaskets. Understanding the specific needs of this engine configuration is crucial for maintaining performance, minimizing downtime, and protecting your investment in critical heavy-duty equipment.

Diesel Pro Power provides premium cylinder head components for the Cummins KTA38, trusted by thousands of operators across the globe. Our components are built to last and are ready to ship for quick turnaround during scheduled maintenance or emergency repairs.

Cylinder Heads for Cummins KTA38

Standard Cylinder Head Assembly

This new cylinder head comes fully assembled with intake and exhaust valves, springs, and valve keepers. It is designed to match Cummins specifications for the KTA38 and its sibling engines. This standard configuration uses hardened washers under the valve springs, delivering a dependable and cost-effective solution for fleet maintenance, backup power generators, and marine propulsion systems.

-

Includes factory-installed valves and valve springs

-

Designed for marine, industrial, and power generation applications

-

Built for drop-in installation and quick replacement

-

Requires 12 units for a complete KTA38 rebuild

Premium Cylinder Head Assembly with Rotocoils

The premium variant of the KTA38 cylinder head is equipped with valve rotocoils instead of washers. Rotocoils promote even valve rotation, which extends the service life of valves and valve seats by preventing localized wear. These heads are ideal for high-load, continuous-duty engines where uptime and performance are paramount.

-

Pre-installed rotocoils beneath valve springs for extended valve life

-

OEM-level quality for high-performance demands

-

Direct replacement for KTA38, KTA50, KTA19, and QSK19 engine configurations

-

12 total heads required for a complete KTA38 rebuild

Gaskets and Seals for the Cylinder Head Assembly

Upper Gasket Set for KTA38

A complete upper gasket set includes all necessary seals for reassembling the top end of the engine after head replacement. This includes valve cover gaskets, rocker lever cover gaskets, exhaust manifold gaskets, injector cam follower cover gaskets, and other related components. Using a full gasket set ensures a reliable seal between mating components and prevents premature leaks.

-

Ideal for full top-end overhauls

-

High-quality materials for heat resistance and durability

-

Includes multiple subcomponents to eliminate sourcing individual seals

-

Recommended when servicing all 12 cylinder heads

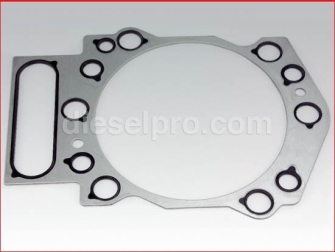

Head Gaskets – One per Cylinder

The Cummins KTA38 requires 12 individual head gaskets—one for each cylinder. These gaskets provide the critical seal between the cylinder block and each head, containing combustion pressures and preventing coolant or oil leakage. Replacing all 12 gaskets ensures long-term reliability and optimal sealing performance.

-

Engineered for high-compression environments

-

Thermal stability across wide temperature ranges

-

Should be replaced whenever a head is removed

-

Sold individually; 12 required per complete engine rebuild

Valve Train Components for Cummins KTA38

Intake and Exhaust Valve Kits

High-quality intake and exhaust valve kits are available for both standard and high-performance configurations. These kits typically include valves made from stellite or inconel materials, depending on application requirements. Inconel is recommended for high-temperature exhaust environments due to its superior resistance to thermal fatigue.

-

Precision-machined for consistent seating and airflow

-

Optional stellite (for durability) or inconel (for heat resistance) valve faces

-

Compatible with both standard and premium cylinder heads

-

Matched for balanced valve movement in all cylinders

Valve Guides and Inserts

Valve guides ensure proper valve alignment and smooth movement within the head. They are available for both intake and exhaust valves. Valve seat inserts, meanwhile, provide a hardened sealing surface and can be replaced during a rebuild to restore factory sealing characteristics.

-

Built to withstand prolonged thermal and mechanical stress

-

Maintains correct valve stem alignment for efficient combustion

-

Compatible with OEM and aftermarket cylinder heads

-

Essential for a complete top-end refresh

Valve Springs, Retainers, and Spring Guides

Valve spring assemblies for the KTA38 include intake and exhaust spring sets, along with upper retainers and lower spring guides. These components are engineered to handle the high lift and seat pressures typical in large-bore diesel engines.

-

Springs available in standard and heavy-duty configurations

-

Retainers and guides designed for secure seating and vibration resistance

-

Replace alongside valves to ensure uniform tension across all 12 heads

-

Helps maintain proper valve timing and seating force

Crosshead Brackets

Crosshead brackets are essential for distributing rocker arm force evenly across valve stems, especially in dual-valve designs. These brackets are machined for strength and longevity, suitable for marine and stationary power units.

-

Ensures balanced actuation of valve pairs

-

Minimizes wear and eccentric loading

-

Integral to long-term valve train durability

-

One bracket per valve pair

Rocker Arms, Push Rods, and Cam Followers

Rocker Lever Housing and Cover Gaskets

These gaskets seal the rocker lever housing and covers, preventing oil leaks and contamination. Proper sealing here ensures that valve actuation components remain lubricated and protected from debris.

-

Made from heat-resistant elastomer or composite materials

-

Designed for the KTA38’s vibration and temperature conditions

-

Should be inspected or replaced during any top-end job

Push Rods for Valve Rocker and Injector Rocker

The KTA38 uses push rods to transmit camshaft motion to the rocker arms. Dedicated push rods are available for both the valve rocker and injector rocker, each designed to specific lengths and materials for precise valve timing and injector operation.

-

Hardened alloy construction for durability

-

Straightness and end geometry inspected for reliability

-

Replace in cases of bending, wear, or scoring

Cam Follower Components

Cam followers transfer camshaft motion to push rods via rollers. Components include rollers and the pins that secure them. In the KTA38, cam followers must be able to withstand continuous contact loads at high RPMs. Proper roller function reduces camshaft wear and maintains engine timing.

-

Heavy-duty rollers and pins for injection and valve actuation

-

Precision fit to minimize play and wear

-

Critical to ensure proper timing and performance

Other Top-End Components

Valve Rotators

Valve rotators help maintain even valve face wear by rotating the valve slightly each time it opens and closes. This is especially useful in high-load marine applications where valves are under constant thermal and mechanical stress.

-

Common in marine versions of the KTA38

-

Promotes uniform valve seating and longer valve life

-

Replace as part of any comprehensive top-end rebuild

Heavy-Duty Fasteners and Hardware

High-load cylinder head environments demand reliable fasteners. Heavy hex nuts used to secure rocker arm adjusters, as well as all necessary bolts for valve train components, are available in corrosion-resistant finishes for marine or coastal environments.

-

Torque-rated for cylinder head and valve train applications

-

Use new fasteners to avoid fatigue failure during reassembly

-

Always use the proper tightening sequence during installation

Exhaust and Intake System Gaskets

Exhaust Manifold Gaskets

These gaskets seal the connection between the cylinder heads and exhaust manifold runners. Heat-resistant materials prevent exhaust blow-by and protect surrounding components from hot gas exposure.

-

Designed to maintain seal integrity under high exhaust pressures

-

Replace with each head service to ensure tight sealing

Intake System Gaskets and Seals

A variety of intake gaskets are available to reseal connections after cylinder head servicing. Proper intake sealing ensures balanced air delivery and optimal combustion efficiency across all 12 cylinders.

-

Durable sealing material for manifold and housing junctions

-

Resists heat cycling and vibration common in large diesel engines

Temperature Sensors and Engine Monitoring Components

Temperature Switches

Temperature switches and sensors are often replaced during top-end overhauls to ensure the cooling system operates reliably. These switches trigger alerts or shut-downs when coolant temperatures exceed safe limits.

-

Helps monitor high-load engine conditions

-

Can prevent catastrophic engine failure due to overheating

-

Should be tested or replaced during rebuilds for added peace of mind

Important Considerations for KTA38 Cylinder Head Servicing

Quantity Matters

One of the most important factors to remember is that the Cummins KTA38 requires 12 of nearly every cylinder head component: 12 heads, 12 head gaskets, 24 valve sets (two per head), 24 valve guides, and so on. When planning a complete overhaul, it’s critical to calculate correct quantities across the board to avoid delays and mismatched parts.

Use Matched Components

Each head should be assembled with compatible valves, springs, guides, and retainers. Mixing standard and premium components across heads can lead to uneven performance or premature wear. Consider either standard or premium builds depending on engine duty cycle, operating environment, and maintenance goals.

Replace All Related Gaskets

A complete top-end rebuild isn’t complete without renewing all associated gaskets—this includes upper sets, cam follower cover gaskets, rocker housing gaskets, exhaust manifold gaskets, and others. Leaks in any of these areas can compromise performance and reduce engine life.

Trusted Source for Cummins KTA38 Cylinder Head Parts

Diesel Pro Power proudly supports over 40,000 customers worldwide with fast shipping and knowledgeable service for Cummins KTA38 parts. Whether you need a single replacement head or a full 12-head overhaul solution, our components are ready to perform in the most demanding industrial and marine environments.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588